Thermal Expansion Valve Function

Thermal expansion valve (short called “TXV” ) is one basic system components for refrigeration cycle. His functions as follow:

1. Throttle and pressure reduction

Throttle and reduce pressure of normal temperature and high pressure liquid refrigerant after condensation in the condenser, adjust the refrigerant which flows through the evaporator, and control the overheat at the evaporator outlet. Overheat = air outlet temperature – evaporation temperature.

2. Regulate flow

According to the temperature signal obtained by the temperature sensor, TXV can automatically adjust the refrigerant flow entering the evaporator to adapt the changes of refrigeration load.

3. Prevent abnormal overheating

The expansion valve adjusts the flow rate to make the evaporator keep a certain overheat, ensure the effective use of the evaporator, meanwhile avoid liquid refrigerant entering the compressor to cause liquid strike; at the same time, it can prevent abnormal overheating.

TXV Classification and Installation

TXV can divide into two types: internal balanced and external balanced.

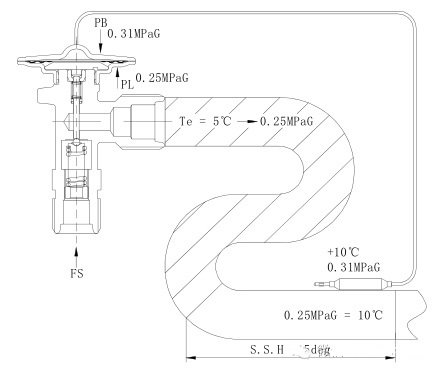

Internal balanced TXV

Temperature sensor pressure = spring pressure + evaporator inlet pressure. Valve diaphragm pressure comes from evaporator inlet.

External balanced TXV

temperature sensor pressure = spring pressure + evaporator outlet pressure. Valve diaphragm pressure comes from evaporator outlet, always used in systems with large evaporator resistance.

TXV Structure

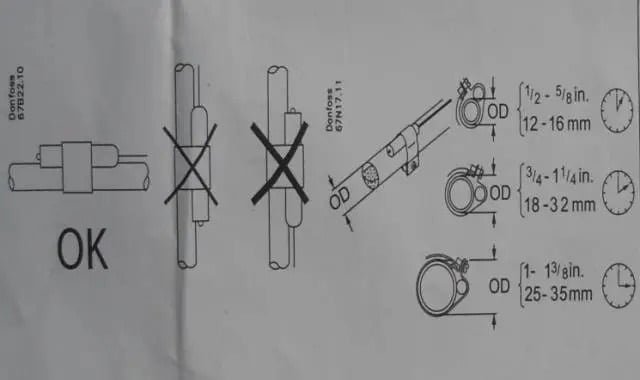

Install temperature sensor onto the horizontal air-outlet pipe at the evaporator outlet, 1.5m away from the compressor suction port. Temperature sensor mustn’t place on the pipeline with accumulated liquid. And wrap it tightly against the pipe, meanwhile clean the oxide scale at the contact in order to expose the metal natural color.

When air-outlet pipe diameter is <25mm, the temperature sensor can be tied at the pipe top; when diameter is >25mm, it can be tied at 45° on the lower side of the air-outlet pipe to prevent oil accumulation at the pipe bottom from affecting temperature sensor performance properly.

Temperature Sensor Installation

TXV Debug

Must debug TXV under normal refrigeration operation condition. If the flow rate is too large, turn the debugging screw half a turn clockwise. Otherwise, turn the debugging screw counter-clockwise, also half a turn. Don’t turn the debugging screw more than half a turn at one time.

There must be an interval of more than 15 minutes between each debug.

TXV overheat should be 5~8℃. If not, adjust it.

TXV Debug Example

Fault: A constant temperature and humidity air conditioner is running with both compressors, air outlet is 22.5℃, air inlet is 16.8℃, its cooling performance is not good. Freon was sufficient, and filter not blocked.

Inspection: 2 compressors’ air outlet was overheated and temperature at the expansion valve outlet was low. The evaporator outlet temperature was 18℃, and air outlet pressure was 3.2kg/cm2 (the corresponding temperature was -5℃, overheat was 23℃), which was obviously deviated from the normal overheat. Reason is the expansion valve wasn’t open enough.

Debug: After correct debug, the evaporator outlet temperature was 12℃, air outlet pressure was 4.8kg/cm2, the corresponding temperature was 4.5℃, and the overheat was 7.5℃.

The specific data before and after the on-site debug are as follows:

| Item | Evaporator outlet Temp (°C) | Compressor air outlet pressure (kg/cm2) | Ralated temp for Compressor air outlet pressure(°C) | Overheat(°C) | Overheat meet the request or not |

|---|---|---|---|---|---|

| Manufacturer's debug standard value | <14 | 4.5~6 | 2.5~11 | 5~8 | Yes |

| (#1 compressor) before debug | 21.0 | 3.2 | -5.0 | 26.0 | No |

| (#1 compressor) after debug | 12.3 | 5.0 | 5.8 | 7.6 | Yes |

| (#2 compressor) before debug | 20.5 | 4.0 | 0.0 | 20.5 | No |

| (#2 compressor) after debug | 13.9 | 5.2 | 6.0 | 7.9 | Yes |

In this debug, the optimal overheat was 7.6℃ and 7.9℃ respectively.

| Item | Air conditioning air outlet | Air conditioning air outlet | Air conditioning air inlet | Air conditioning air inlet | Temp gap between air inlet and outlet |

|---|---|---|---|---|---|

| Unit | Temp (°C) | Humidity (%) | Temp (°C) | Humidity (%) | (°C) |

| Before debug | 22.5 | 54.8 | 16.8 | 75.4 | 5.7 |

| After debug | 22.5 | 54.8 | 14.3 | 84.3 | 8.2 |

Conclusion

At last, thermal expansion valve (TXV) plays a vital role in regulating refrigerant flow and ensuring optimal system performance.

By understanding its functions, classifications, proper installation, and debugging techniques, you can maintain efficient operation and address potential issues effectively, contributing to the reliability of the refrigeration or air conditioning system.

Any comments?

Welcome leave a message or repost.