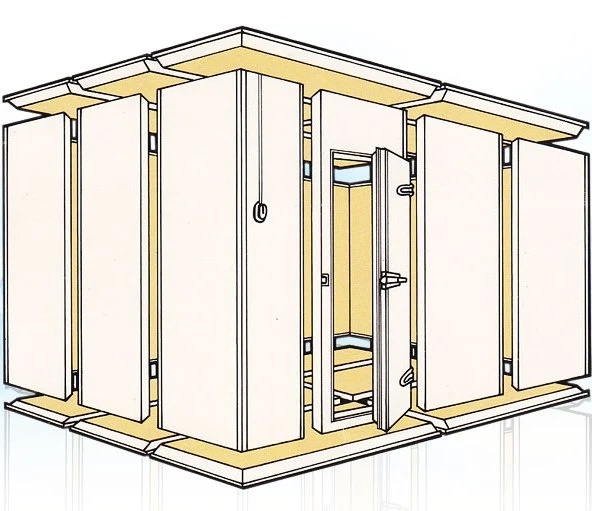

One-Stop OEM & ODM Cold Room Solution Partner

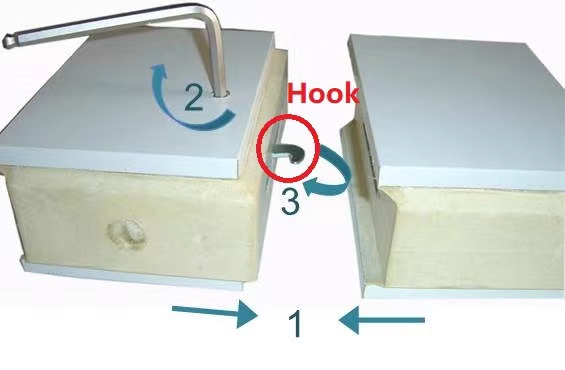

Our China Factory Fabricates All Sizes High-Level Cold Room Panel As Your Demand

We produce PU/ PIR/ XPS cold room panels with width: 900 /1000 /1100mm; thickness: 50 /75 /100 /120 /150/180 /200 /250mm. With Galvanized Plate/ Color Steel/ Stainless Steel sheet. Or custom your request, contact us Now !