One-Stop OEM & ODM Solution Partner

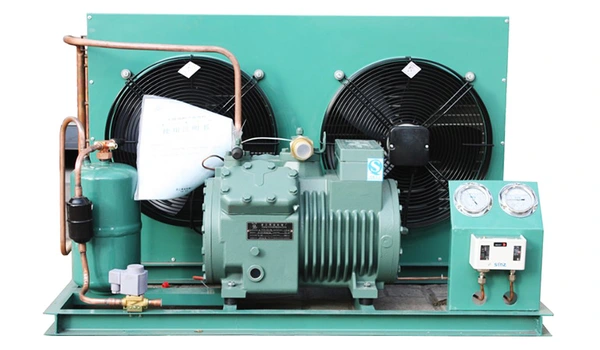

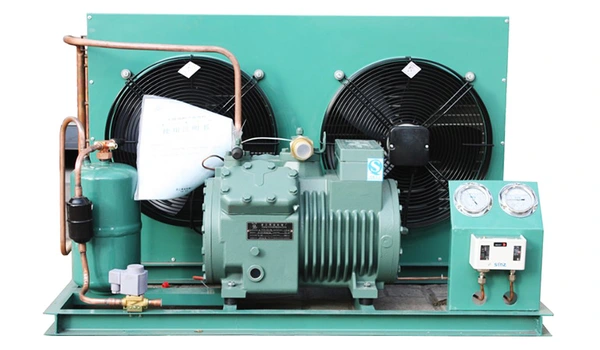

Condensing units (also called”refrigeration unit” or “cold room outdoor unit”) are used for refrigeration of various equipments. Main components: compressor, condenser, expansion valve, fan motor, control board and pipeline, etc.

Compressor is the most important equipment in the condensing unit, usually called “main engine”. Refrigerant changes from low pressure to high pressure and the continuous flow and transportation are all accomplished by the work of the compressor.

Speedway is a condensing unit manufacturer in China, produce both inverter and non-inverter condensing unit.

Our factory manufactures condensing unit from 0.75hp (horse power) up to 50hp, of course also can customize your requirements. Our equipments are suitable for Cold Room, cold storage, container, hospital drug cold chain, seafood cold chain, cafe room, or any other commercial purpose places in where you want to cooling the space.

What’s more, we also produce Cold Room Panel, Cold Room Door, Unit Cooler (evaporator), drying room panel which equiped with our condensing unit or your existing cooling system.

Warmly wish to cooperate with you.

Cold Room Panel and Refrigeration Unit

Self-Contained Refrigeration Unit

Semi-Hermetic Condensing Unit

Super Low Temp Refrigeration Unit

Monoblock Condensing Unit

Inverter Condensing Unit

Mobile Refrigeration Unit

Hermetic Condensing Unit

Clients Priority, Quality is Everything! We have 6 production lines for condensing unit, use world famous brand compressor and parts to ensure every unit ranked top quality.

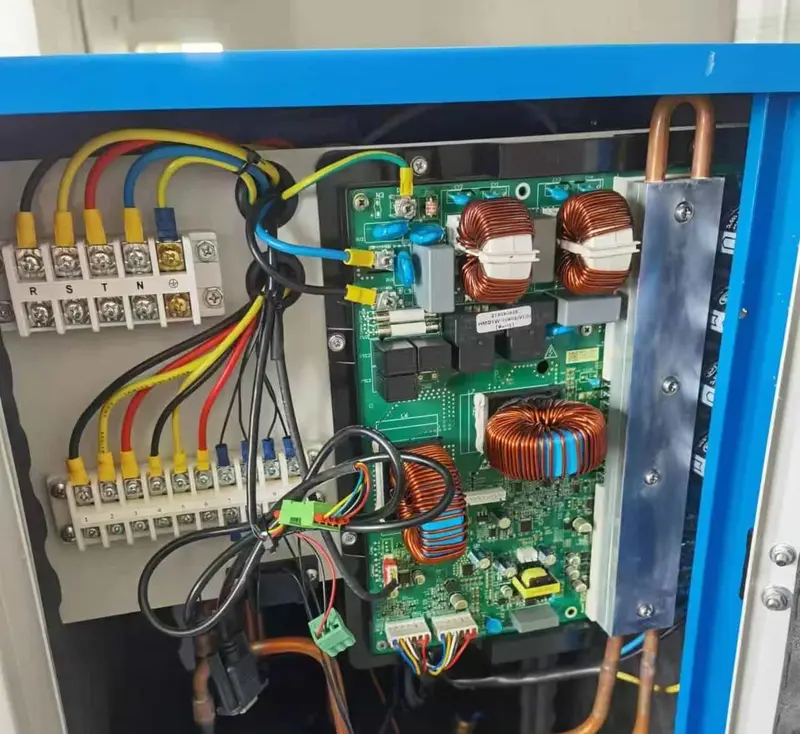

Inverter Condensing Unit Can Save 50% Energy and Cooling Time

Very Suitable For Voltage Un-stable Area, Never damage Compressor

Inverter CDU Board

Custom Display

Unique Design 5HP Inverter Board

Custom Inveter Board

Sight Glass

Filter Dryer

Oil Separator

TXV Valve

Condensing unit mainly used for food storage, pharmaceutical storage, flowers, chemical storage, hotel industry, cold chain logistics, wine storage, seedling cultivation, supermarkets, and other industries. Meanwhile, used for the production, storage and logistics for all kinds of food, agricultural products and other commodities which needed a constant temperature environment.

Seafood

Flower

Seedling Cultivation

Chemical Material

Agriculture

Cold Chain

Pharmaceutical

Wine

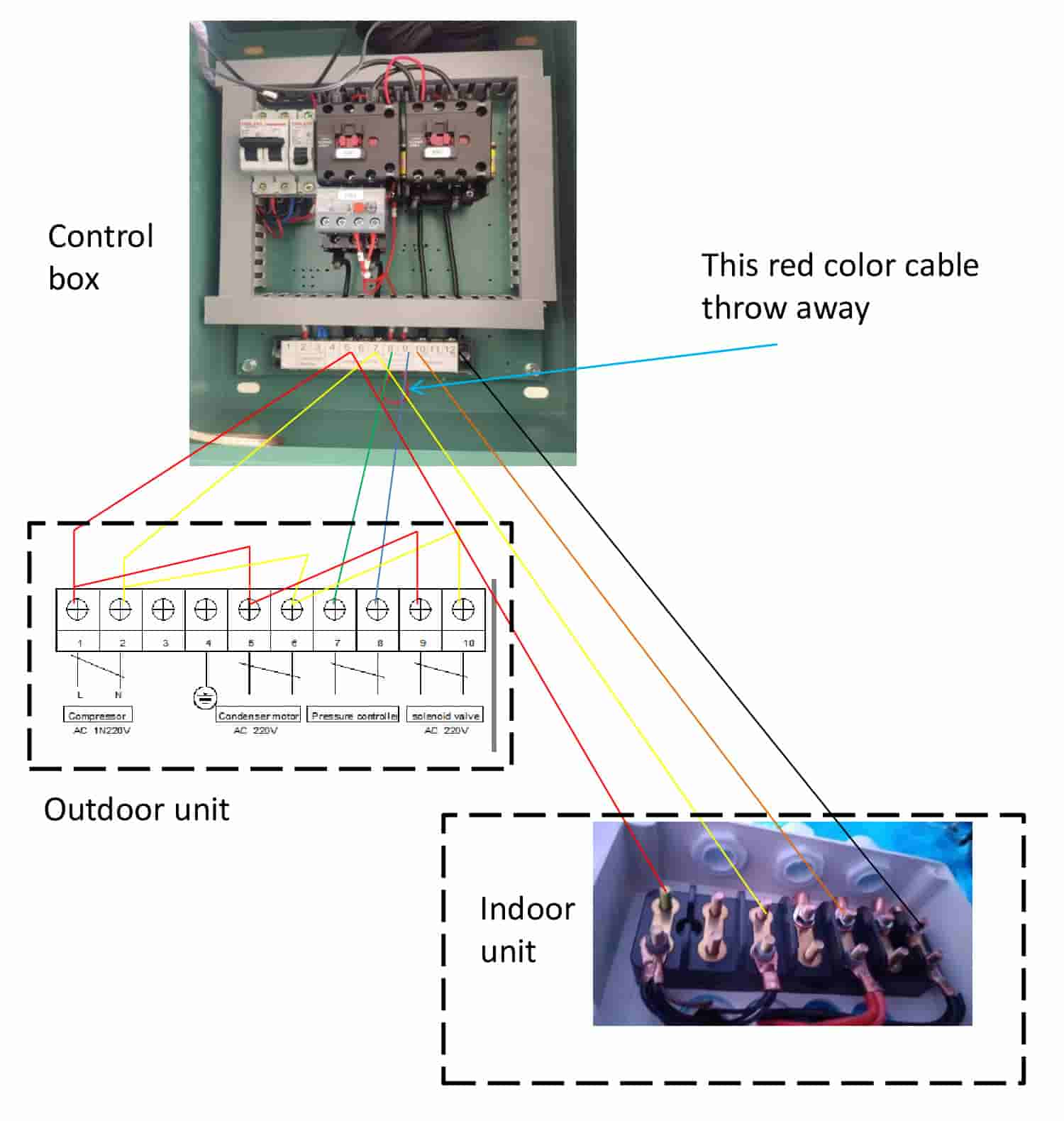

Control box line color :

Red is “5”

Yellow is “7”

Green is “8”

Blue is “9”

Brown is “10”

Black is “12”

Attention: The colors only demonstrate how to connect different terminals properly, not cables’ color.

Outdoor unit: Cold room condensing unit circuit diagram

Indoor unit: Cold room Unit Cooler (evaporator) circuit diagram

Attention: For original whole diagram, please Contact Us freely.

No worry, our cooling capacity tonnage calculator will help you !

When you want to wholesale condensing unit,or act as a dealers.

# Firstly you should double think some questions: what is your selling market features? What is your selling channels? Who is your competitor? etc. they are very important for us before giving you the final solution.

#1 Application

If you want to cool a whole project for cold room, container (20ft/40ft), supermarket, the household split type Air Conditioners are not suitable. As their application areas are so different.

Application areas for condensing unit:

2hp 10~20m2; 3hp 15~25m2

4hp 20~40m2; 5hp 30~55m2

6hp 40~80m2, etc.

(HP means Horse Power)

Due to working temperature ( high, medium, low) the application areas are different even the same hp.

So please give your drawings and all information, we will supply you the solution.

#2 Refrigerant

Different refrigerants have different prices, also most countries are forbidden R22 refrigerant (Not R22 compressor), so double check your market or government the related policy, don’t make big mistake.

For condensing unit or refrigeration unit, there are more refrigerants’ options, like R404, R448a, R134a, R449a, etc. Let’s know your option or project details.

#3 Inverter or Non-inverter

Most people are puzzled by two types cooling way: inverter or non-inverter. In one word: Inverter condensing unit is more energy-saving, more stable, more bigger cooling area, better for low-voltage areas. Of course, price is higher.

#4 Pricing

According to different working temperature & room size, we will recommend the most suitable & competitive refrigeration products.

What’s more, different compressors ( Copeland / Sanyo / Panasonic / Highly ) have different prices.

For condensing unit or refrigeration unit, you can choose from 0.75hp up to 50hp or even more.

#5 Reputation

Before confirming the order, should first verify the authenticity of supplier, if possible please visit the factory before purchasing

the products, what’s more, can ask for some sample for testing then you will have a brief understanding about this company and their managenment.

#6 Required Temperature

Different stored goods have different temperature requirements, and the cooling power is also different.

For example, the delivery of frozen food such as ice cream generally requires a low temperature of -18°C, transportation of chilled meat requires -5°C, and the required temperature for fresh fruits and vegetables is also different. Especially for the cold chain transportation of vaccines and medicines,which need special requirements of temperature.

Therefore, need selecting the suitable condensing unit or refrigeration unit according to the different temperature requirements.

In addition, some goods also require the refrigeration unit to have a defrosting function during transportation.

#7 Hermetic Way

Cold storage refrigeration compressors can be divided into two categories: semi-hermetic and hermetic due to their structure.

1) Semi-hermetic refrigeration compressor:

It can adapt to a wider pressure range and cooling capacity requirements. Thermal efficiency is higher, cooling effect is more stable, and the unit power consumption is less. But the price is much expensive.

2) Hermetic sealed refrigeration compressor:

The compressor and motor are installed in a welded or brazed shell, and share a main shaft, which not only cancels the shaft sealing device (decrease the possibility of leaks), but also greatly reduces size and weight of the entire compressor. But its price is cheaper than the semi-hermetic type.

#1 Package

Brand new condensing unit should use hard and sturdy wooden (Fumigation Free) package, firmly fixed. No broken or damage.

#2 Casing

Normally use zinc plated iron sheet, which has anti-rust function. The more even plated, the more better function of anti-rust. Of course, you can use stainless steel (SS) material, neven corrosion.

#3 Parts Condition

All parts should be brand new, especially the compressor, some suppliers use second-hand or refurbished compressor to cheat clients, whose quality is very unstable.

#4 Welding

Qualified products will have dwell time for pressure one week or more before delivery to prevent any refrigerant leakage. Bad welding will easily leak refrigerant, bringing big money loss for clients.

#5 Compressor Type

Less than 3hp usually use rotary compressor ( Copeland / Sanyo / Highly ), more than 3hp use scroll compressor ( hermetic condensing unit) or piston compressor ( semi-hermetic condensing unit).

#6 Noise

Brand new evaporator & condensing unit shouldn’t have a big noise (more than 45DB) when runs in 30 minutes, otherwise the compressor or fan (motor) uses poor quality, this kind of evaporator or condensing unit is not qualified.

#7 Voltage and Frequency

Condensing unit less than 3hp uses 220V normally ,but we also supply 380V. More than 3hp usually adopt 380-440V. What’s more, you should confirm your frequency , 50Hz or 60Hz, the unit price is different and misuse will damage your compressor even the whole condensing unit.

Frequently Asked Questions About Condensing Unit

Condensing unit is responsible for condensing refrigerant vapor into liquid form by releasing heat, allowing the refrigeration system to remove heat from the desired space, finally cool down the room.

Speedway is committed to quality across all aspects of our business – our people, processes and products. We call this ‘the SPEEDWAY standard’.

The condensing unit receives high-pressure, high-temperature refrigerant vapor from the compressor. The refrigerant flows through the condenser coil, where it releases heat to the surrounding air or water, causing it to condense into a liquid, finally cooling the space or medium.

We welcome any sample order before big quantity purchase, that means 1pc is acceptable. For mass order quantity is 10pcs each model.

The two main types of condensers used in condensing units are air-cooled condensers, which use fans to blow air over the condenser coil, and water-cooled condensers, which circulate water to remove heat from the refrigerant.

We have own factory to produce the main refrigeration products, but we also do trading for other related products because we have resource to supply good quality and service.

Sizing a condensing unit involves determining the cooling capacity required for the specific application. Factors such as the desired temperature, ambient conditions, and the type of refrigerant will determine the appropriate capacity.

For details request please email us: sales@cn-beyond.com

Yes,we have 5 senior engineers, 13 professional r & D team, 65 professional production personnel.

Regular maintenance of a condensing unit includes cleaning the condenser coil, checking and replacing air filters, inspecting electrical connections, ensuring compressor proper lubrication,etc. It’s also important to monitor and maintain the appropriate refrigerant levels.

We support payment through wire transfer, like T/T, L/C, Western Union. Also accpet Paypal payment for sample piece order.

For sure. You can send us your logo, package, design, technical specification, we will give you the final satisfied solution accordingly without additional cost !

Common issues with condensing units may include refrigerant leaks, compressor failures, fan motor malfunctions, clogged condenser coils, or issues with control and safety devices. Regular maintenance and Prompt Troubleshooting can help address these problems.

Yes, we did. Our factory has inner 100% inspection for each unit before loading, also can make the legal test report for each shippment. What’s more, can invite SGS / TUV / BV inspection according clients’ request, but customers should pay for the test fee.

First, we need starting the business to understand each other, if things move smoothly and you meet our “distributor request”, then we will sign the formal contract and agreement to ensure your rights in your market.

Contact our salesman for more details please.

While condensing units are typically installed outdoors, there are indoor installation options available. Indoor condensing units require proper ventilation and may require additional considerations for air circulation and condensate drainage.

The lifespan of a condensing unit can vary depending on factors such as maintenance, usage, and environmental conditions. On average, a well-maintained condensing unit can last 12~15 years or more.

When working with a condensing unit, it’s important to follow appropriate safety measures such as disconnecting power before performing maintenance or repairs, wearing personal protective equipment (PPE), and following proper handling procedures for refrigerants to prevent injury or accidents.

Partner with us to increase your brand reputation, get an impressive experience for your clients to remember you lifelong, and help you stand out in the competitive market !

Email:

sales@cn-beyond.com

cn-beyond@hotmail.com