Description

What is explosion proof air conditioner?

Explosion-proof air conditioner is a special cooling system to operate safely in environments where there’s a risk of explosion due to the presence of flammable gases, vapors, or dust.

These Air Conditioners are built with materials and features that prevent sparks or other ignition sources from causing explosions in hazardous areas.

Explosion proof air conditioner classification

Explosion-proof air conditioners are classified according to the hazardous environments they operate in. The classification based on the type of hazardous substances present and the likelihood of an explosion occurring.

Class I: This classification pertains to locations where flammable gases or vapors are present in quantities sufficient to produce explosive or ignitable mixtures.

Class I is further divided into:

Class I, Division 1 (Div 1): Areas where flammable concentrations of gases or vapors are likely to exist under normal operating conditions.

Class I, Division 2 (Div 2): Areas where flammable concentrations of gases or vapors are not likely to exist under normal operating conditions, but may occasionally be present.

Class II: This classification applies to locations where combustible dust is present in sufficient quantities to potentially produce explosive mixtures.

Class II is further divided into:

Class II, Division 1 (Div 1): Areas where combustible dust is regularly present in sufficient quantities to create a hazardous atmosphere.

Class II, Division 2 (Div 2): Areas where combustible dust is not present in sufficient quantities to create a hazardous atmosphere, but may accumulate and become a hazard.

Class III: This classification covers locations where ignitable fibers or flyings may be present but are not likely to be suspended in the air in quantities sufficient to produce ignitable mixtures.

Class III is further divided into:

Class III, Division 1 (Div 1): Areas where ignitable fibers or flyings are present in quantities sufficient to create a hazardous atmosphere under normal operating conditions.

Class III, Division 2 (Div 2): Areas where ignitable fibers or flyings are not normally present in quantities sufficient to create a hazardous atmosphere, but may accumulate and become a hazard under abnormal conditions.

Explosion Proof Air Conditioner Parameter

| Model | BKFR-26GW/1HP | BKFR-35GW/1.5HP | BKFR-50GW/2HP | BKFR-72GW/3HP |

|---|---|---|---|---|

| Capacity(Horsepower) | 1.0HP | 1.5HP | 2.0HP | 3.0HP |

| Capacity(BTU) | 9000BTU | 12000BTU | 18000BTU | 24000BTU |

| Function | Cool and Heat | Cool and Heat | Cool and Heat | Cool and Heat |

| Cooling capacity power | 2650W | 3500W | 5000W | 7200W |

| Heating capacity power | 2920W | 3850W | 5800W | 8000W |

| Power supply | 220V 50/60Hz | 220V 50/60Hz | 220V 50/60Hz | 220/380V 50/60Hz |

| Cooling input power | 810W | 1068W | 1600W | 2350W |

| Heating input power | 810W | 1200W | 1680W | 2650W |

| Electric heat power | 900W | 1000W | 1200W | 1000W |

| Cooling current | 3.7A | 5.4A | 7.3A | 10.8A |

| Heating current | 3.7A | 5.8A | 8.2A | 12.2A |

| Energy Efficient Ratio | 3.6 | 3.6 | 3.6 | 3.6 |

| Volume(m3/h) | 541 | 631 | 851 | 1101 |

| Noise(indoor/outdoor) dB | 35/40 | 37/42 | 40/53 | 46/57 |

| Water proof grade | IP54 | IP54 | IP54 | IP54 |

| Refrigerant | R410a | R410a | R410a | R410a |

| Suitable area | 10-18 m2 | 15-24 m2 | 22-34 m2 | 35-50 m2 |

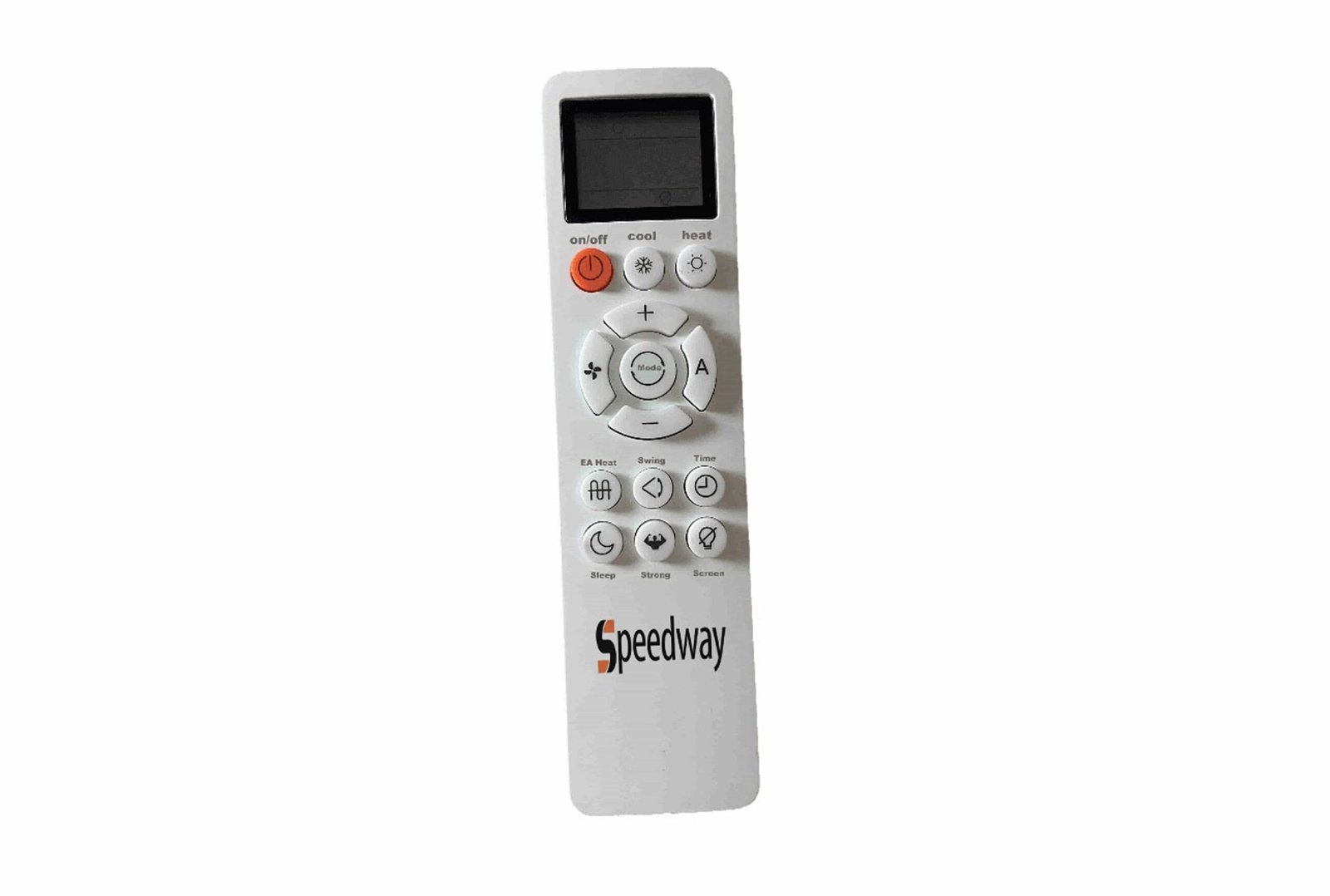

| Control mode | Remote control | Remote control | Remote control | Remote control |

| Display screen | LED | LED | LED | LED |

| Cleaning way | Automatic | Automatic | Automatic | Automatic |

| Indoor unit dimension | 776*268*186mm | 844*300*183mm | 940*298*200mm | 1078*326*253mm |

| Outdoor unit dimension | 776*540*320mm | 848*540*320mm | 995*700*396mm | 980*790*427mm |

| (Indoor / outdoor) weight | 25 / 31kg | 26 / 35kg | 29 / 52kg | 35 / 70kg |

———Differences Between Normal and Explosion Proof Air Conditioner———

Safety Features

Normal Air Conditioner:

Don’t incorporate safety features to prevent explosions in hazardous environments.

Explosion-Proof Air Conditioner:

Have safety features such as sealed enclosures for electrical components, explosion-resistant materials, and special motors and controls that minimize the risk of sparking or overheating in potentially explosive atmospheres.

Intended Use

Normal Air Conditioner:

Suitable for use in residential, commercial, and industrial places where there is no risk of explosion from flammable gases, vapors, or dust.

Explosion-Proof Air Conditioner:

Used in hazardous environments where the presence of flammable gases, vapors, or combustible dust poses a risk of explosion. They are commonly used in industries such as oil and gas, chemical processing, pharmaceuticals, and mining.

Enclosures and Sealing

Normal Air Conditioner:

Have open or partially enclosed electrical components, which may allow sparks or arcs to escape and ignite flammable substances.

Explosion-Proof Air Conditioner:

Feature fully sealed enclosures for electrical components to prevent any sparks, arcs, or heat from escaping and igniting hazardous substances in the surrounding environment.

Materials and Construction

Normal Air Conditioner:

Constructed using materials like plastic or lightweight metals, which may not withstand the rigors of hazardous environments or provide sufficient protection against explosions.

Explosion-Proof Air Conditioner:

Built with robust materials such as stainless steel or aluminum alloys, which offer enhanced durability and resistance to corrosion and can withstand the conditions of hazardous areas.

Cost

Normal Air Conditioner:

More affordable for use in non-hazardous environments.

Explosion-Proof Air Conditioner:

Special equipment for use in hazardous locations, and as such, they come with a higher initial cost due to their special construction, components, and certification requirements.

————Frequent Asked Questions————

1. Can explosion-proof air conditioners operate in extreme temperature?

Yes, many explosion-proof air conditioners can operate effectively in extreme temperatures, ranging from very low temperatures in arctic environments to high temperatures in desert regions (-30℃ ~ +55℃). Our units have robust components and insulation to withstand harsh temperature conditions.

2.Do explosion-proof air conditioners require special installation?

Yes, you should have expertise person, who is familiar with the requirements of hazardous locations and applicable regulatory standards, to make the installation.

3. Can explosion-proof air conditioners be used in outdoor environment?

Yes. Our units have weatherproof enclosures and components to withstand exposure to elements such as rain, wind, and sunlight.

4. What are the maintenance requirements for explosion-proof air conditioners?

Maintenance requirements include: routine checks, filter replacement, cleaning of components, and inspection of seals and enclosures to ensure continuous safe operation.

Should carry out maintenance procedures according to Air Conditioner Manufacturer regulatory guidelines.

5. What certifications are required for explosion-proof air conditioners?

Certificates have ATEX (Europe), NEC (USA), or IECEx (International) , which can ensure compliance with safety requirements for use in hazardous locations.

6. Are explosion-proof air conditioners resistant to corrosion?

Yes, they use corrosion-resistant materials such as stainless steel or aluminum alloys. These materials help protect the units from corrosion caused by exposure to moisture, chemicals, or other corrosive substances present in industrial environments.

7. Are explosion-proof air conditioners suitable for use in offshore installation?

Yes, they can use in offshore installations such as oil rigs and platforms, where the presence of flammable gases and harsh environmental conditions necessitate the use of special equipment for safety.