Whether the refrigerant charge of refrigeration equipment is too much or too little, it will cause facility abnormality, such as: decreased cooling capacity & EER, shortened equipment life, increased input power, etc. So how can we judge whether the refrigerant charge is correct ?

Some commonly used judgment methods as follow:

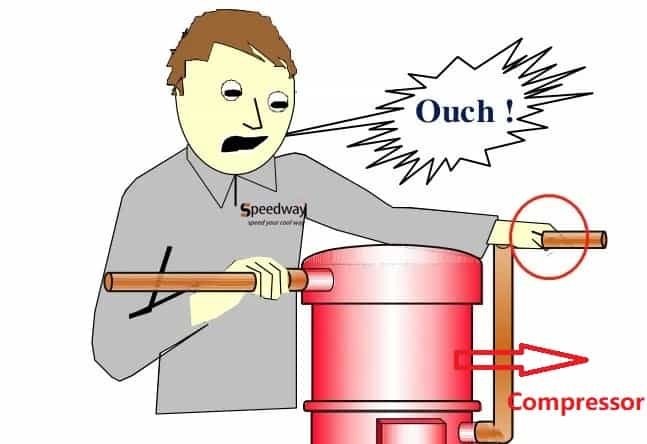

Touch Compressor Pipeline by Hand

Everyone feels hot or cold differently. Usually, the human body feels hot when the temperature is >37℃, and feels cold when the temperature is <37℃. The temperature limit of skin perception is 49℃.

When you touch compressor suction and discharge pipe and feel that they aren’t cold enough, that means the refrigerant charge isn’t enough.

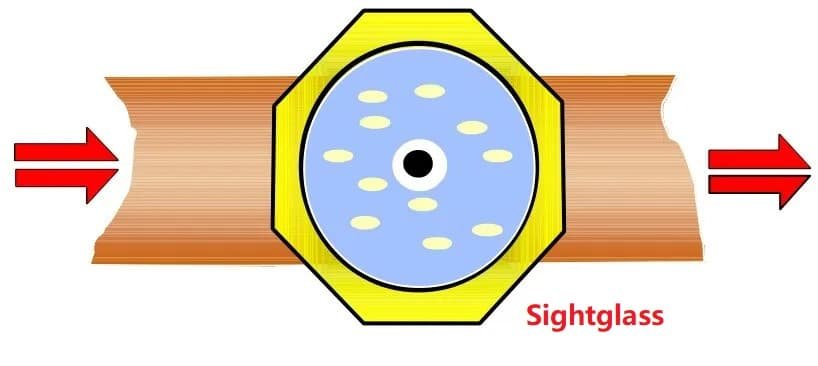

Watch Sightglass Bubble

Bubble indicates refrigerant absence and loss of liquid line pressure. If the liquid line pressure loss is severe, the liquid refrigerant will quickly evaporate into gas. This gas will reduce refrigerant flow when flowing through the expansion valve (TXV) and cause its damage. If the system is not cooled enough, the pressure loss can easily cause bubbles in the sight glass.

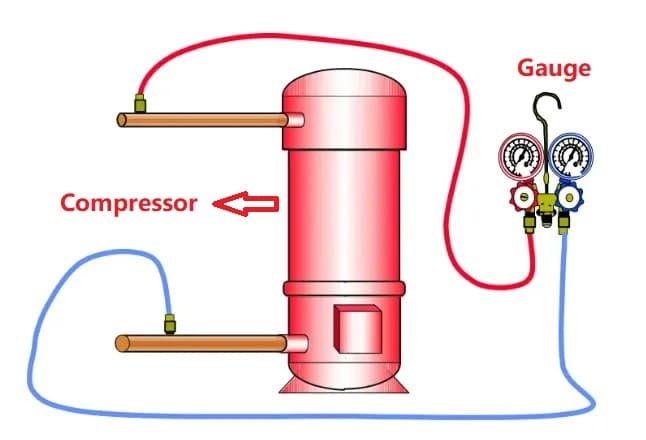

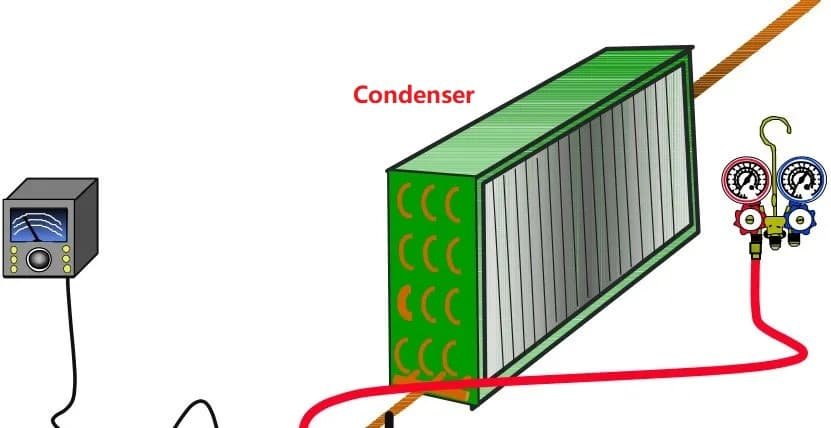

Test Refrigerant High-Low Pressure

Firstly, you must ensure both condensation air volume and evaporation air volume meet the international standard. If the two fail to match, it will directly affect the accuracy of the refrigerant pressure test.

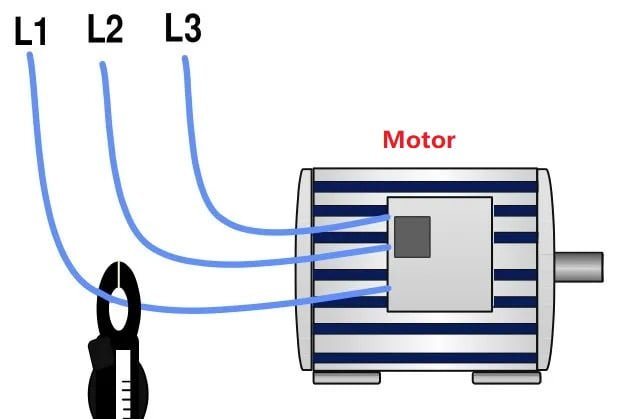

Test Compressor Current

Compressor current will behave differently in different situations. For example, it will be affected by the main power voltage value, a small deviation in voltage may cause a significant deviation in current.

In addition, the current is also subject to the lubrication condition of the motor bearings and changes in temperature.

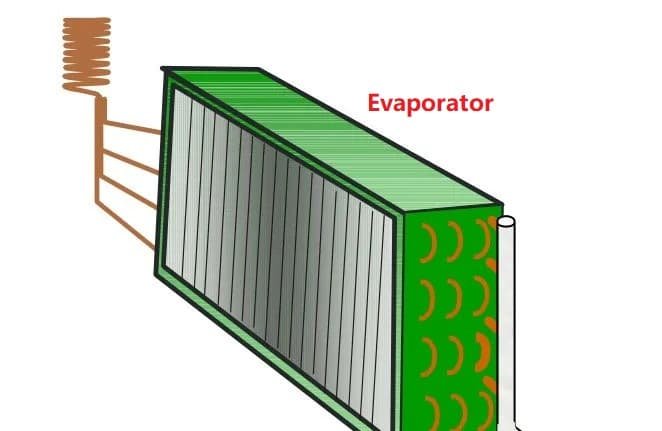

Calculate Superheat

Calculate superheat by measuring the suction temperature & pressure of suction pipe on the evaporator. The pressure value is converted into temperature value, then minus suction temperature value, the difference is called superheat.

For the capillary system, measure the correct capillary flow depends on the pressure and resistance. For the expansion valve system, it is easy to overcharge. Since the expansion valve will automatically open and close.

The superheat of the expansion valve system is 7~8℃.

Calculate Subcooling

Calculate Subcooling by measuring the liquid temperature & pressure values on the liquid pipe. The pressure value is converted into temperature value, then minus liquid temperature value, the diference is subcooling, which is equivalent to the condensation degree of the refrigerant liquid in the condenser.

If subcooling is low or non-existent, you can see the bubbles (caused by the drop in liquid pipe pressure) in the sight glass. The subcooling of the expansion valve system is 8~12℃. Subcooling degree only represents the condensation effect.

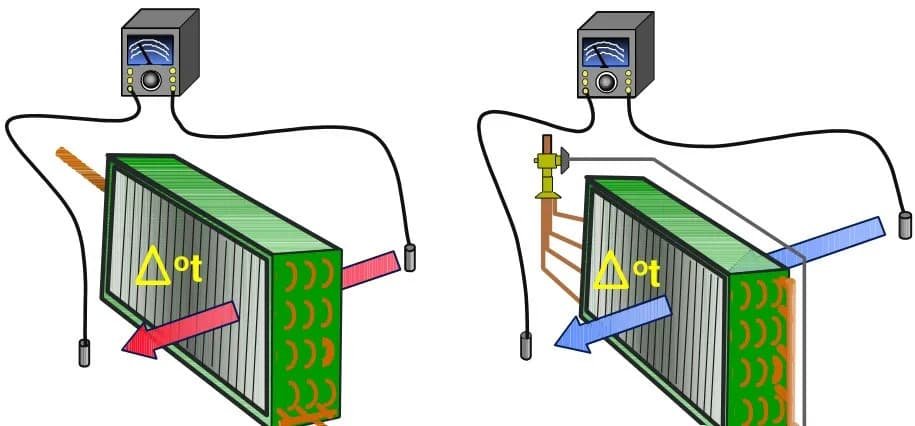

Calculate Inlet and Outlet Air Volume Temperature Difference

Temperature difference of air-cooled condenser is 16.7℃, and temperature difference of the evaporator is 11.1℃. Under high latent heat load, evaporator “△t” will decrease. So excessive injection, in order to obtain a higher “△t”, will be detrimental to compressor operation.

Since the air volume will affect “△t”, the condenser and evaporator air volumes must be correct before measuring “△t”.

Suction Pipe Condensation

This method depends on the refrigerant liquid flow rate of the capillary tube and the pressure difference at both ends.

If the evaporator air volume is normal, the refrigerant flows through the evaporator according to the load change, and no frost will form. If the load decreases, the liquid refrigerant will flow through the evaporator and enter the suction pipe.

The water vapor in the surrounding air will condense on the copper tube, iIf there is enough liquid refrigerant.

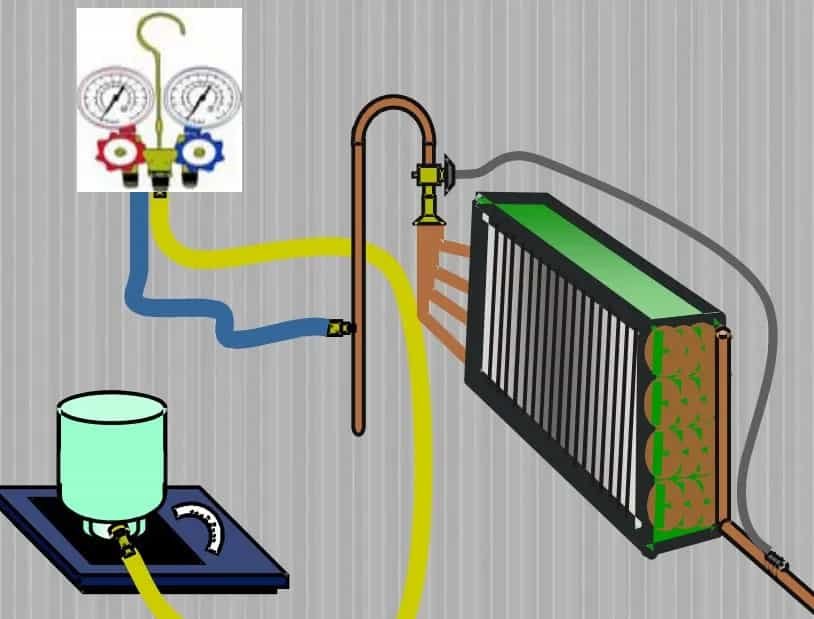

Weigh Charge

Weighing is the most effective way to calculate refrigerant charge!

First, recover refrigerant, then evaculate the refrigeration system, and finally refilled by weighing.

This method is the most accurate no matter what kind of refrigeration system it is.

Conclusion

At last, accurately judge the correct refrigerant charge is essential to ensure the efficiency and lifespan of cooling systems.

By applying the outlined methods, such as pressure readings, superheat and subcooling measurements, and performance monitor,etc, you can maintain optimal system operation and prevent issues caused by overcharge or undercharge.

Any comments?

Welcome leave a message or repost.