One-Stop OEM & ODM Cold Room Solution Partner

Our China Factory Fabricates and Designs All Sizes Unit Cooler for Cold Room

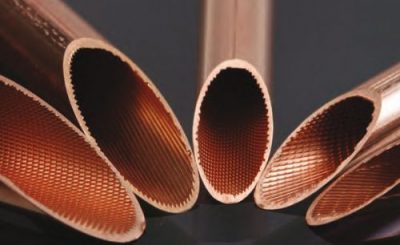

We customize all types unit cooler ( evaporator unit, indoor unit) with different size, fin spacing and material, fan diameter is 300~700mm or even more, contact us for details.