OEM w jednym miejscu & Partner rozwiązań ODM

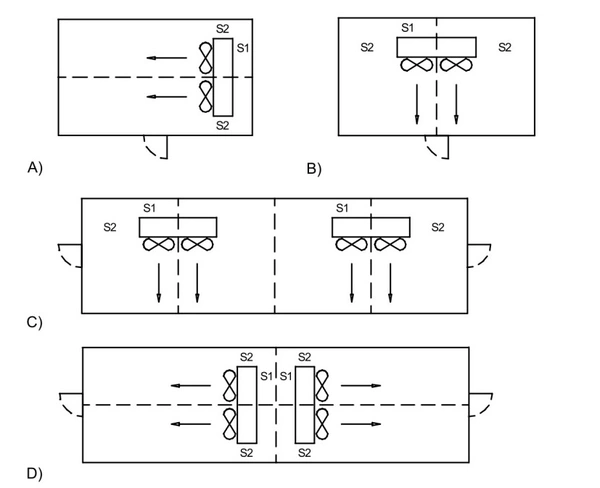

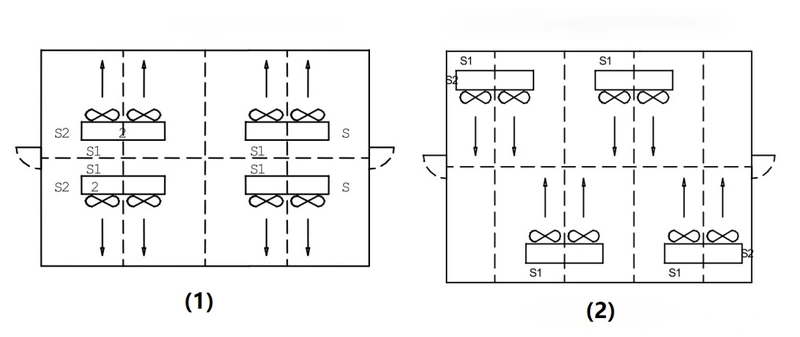

Nasza fabryka w Chinach produkuje chłodnice jednostkowe wszystkich rozmiarów do chłodni

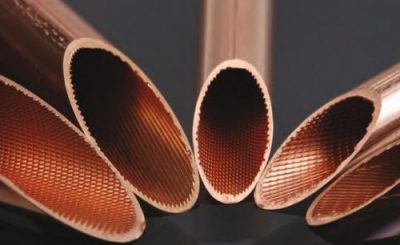

Dostosowujemy chłodnice wszystkich typów ( parownik, urządzenie wewnętrzne) o różnym rozmiarze, rozstaw żeberek i materiał, średnica wentylatora wynosi 300 ~ 700 mm lub nawet więcej, skontaktuj się z nami, aby uzyskać szczegółowe informacje.