Many bars need beer cold storage, so how do you build it? Do you know the procedures? And you should know the ways how to save your cost, etc.

Let’s talk today.

How To Choose The Right Cold Storage

How to Select the Correct Cold Storage Space

Must select according to the number of tap handles:

| Numbers of Tap Handle | 8-12PCS | 13-20PCS | 21-30PCS |

|---|---|---|---|

| Recommended Area | 5-8SQM | 7-10SQM | 10-15SQM |

Conclusion: Roughly, the area of cold storage is HALF of the tap handles’ number.

Attention: you should consider the electricity consumption and cleaning problems of cold storage. What’s more, the application of space.

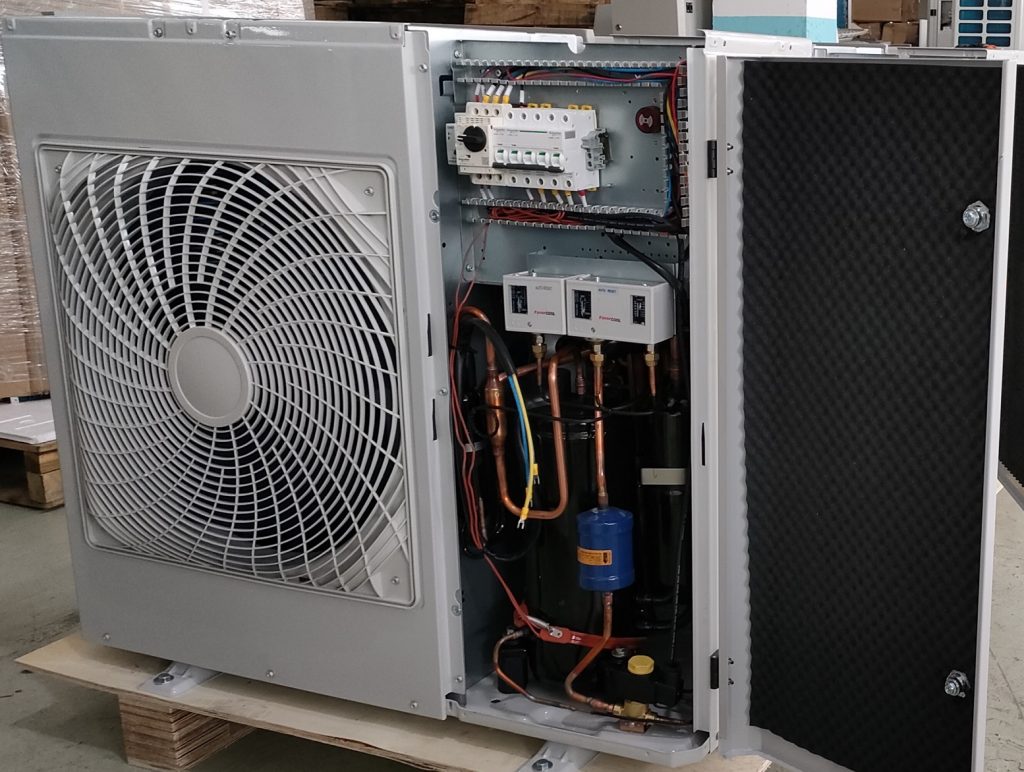

How to Choose the Power of the Cold Storage Condensing Unit

Condensing Unit basically needs 2-5hp (hp=horsepower), depending on the size of the cold storage.

Power of Condensing Unit

The general price of entire project is 3,000-4,500 USD, and a slightly larger area project doesn’t exceed 7,500 USD.

Cold Storage Material

Insulation material for cold storage

Must choose Fire-Resistant Panel materials!

Test method: Tear off a small piece of the material and ignite it. If burning, means not fireproof; The fireproof material will extinguish itself after burning.

In addition to the side and top, ground layer of cold storage must be insulated. Otherwise, the heat will lose from the ground layer.

The ground layer must be sturdy and wear-resistant, such as using a non-slip aluminum plate or bamboo plywood, to prevent the beer barrels from damaging the ground during transportation.

Must have a sewer pipe on the floor to facilitate cleaning.

The Thickness and Insulation of the Wall

If bar or tap handles are just outside the cold storage, the thickness of the wall should be 10cm-15cm. Too thick will lead to excessive cooling loss and beer quality problems.

Thickness of The Cold Storage Wall

Cold Storage Precautions

Goods in the cold storage

Barreled beer must obey FIFO ( First-In First-Out) system, maintaining a reasonable circulation.

FIFO System

Don’t put food in cold storage !!

Vegetables and meat will have bacteria and microorganisms, which will destroy beer quality.

If too many barrels are stacked in the cold storage, you can make a shelf to increase the space to place the barrels more reasonably.

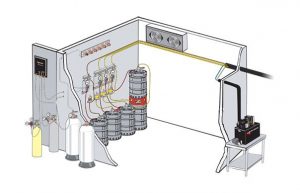

Precautions for Installing Beer Dispensing Equipment

Equipment installation must be reasonable. Equipment such as barometers (need debugging frequently) must be installed in an easy location to debug them in time.

There will be many pipes after installation, and the wiring is particularly important. In the case of ensuring the appearance, the layout must be reasonable, and the length & distance of the wiring must be well-controlled.

Beer Dispensing Equipment

Cold storage temperature should be above 0°C (recommended at 1-2°C), not below 0°C.

Beer should be far away from the evaporators to avoid freezing.

Cold Storage Safety

Do not store CO2 gas cylinders in cold storage

The humidity in the cold storage is high, which will corrode the parts of the gas cylinder and cause gas leakage or other safety accidents; Once the gas leaks, the oxygen in the cold storage will be discharged, forming an oxygen-deficient environment, which may cause suffocation.

Gas needn’t be refrigerated, that is a waste of electrical energy.

We recommended punching holes and putting the CO2 cylinder outside the cold storage.

Remember to keep the hole well-insulated as well.

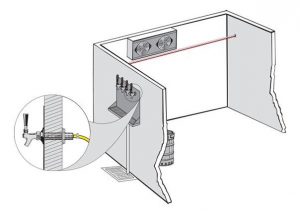

Use Two-way Door

Many cold storages in bars use one-way doors. If the staff closes the door after entering or the people passing by close the door, the person inside won’t be able to open it, which will cause personal risk.

So we recommended choosing a two-way door, people inside can also open it.

Two-way Door for Cold Storage

The Best Distance Between Cold Storage and Tap Handles

There are 2 types of cold storage beer out systems:

1. Straight-out system

The shorter the better, as straight-out system saves costs.

Distance between cold storage and tap handles

2. Long-distance system

If the distance between tap handles and cold storage is more than 10 meters, you should use a water chiller. If the pipeline is too long, will lead to a greater energy loss, which means more cost for you.

Also need to adjust the barometer accordingly.

Temperature Measurement in Cold Storage

Cold storage temperature is always a concern for everyone, so how to measure the temperature?

You can buy a special thermometer for cold storage, put it in the cold storage, then you can check the temperature in real-time.

Gas Blend Calculator

But the more professional suggestion is: Put a water-filled bottle in the cold storage and insert a thermometer.

This method can more accurately detect the temperature of the water, that is: check the temperature of the beer in the barrel of the cold storage.

Temperature Measurement in Cold Storage

Follow-ups after the Cold Storage Installed

Usually, after the new cold storage installation, there will be pungent odors (electric welding smell, paint smell, etc.). Therefore, you need to disinfect and inspect the cold storage.

Follow-ups after installation:

1. Do the necessary anti-corrosion treatment for the stored items. Carry out pre-cooling work to achieve the best effect on temperature, humidity, and gas composition.

2. Adjust the suitable temperature control range (0~5℃).

3. Read the instructions carefully before the cold storage condensing unit first runs, to fully understand the performance characteristics and operational specifications of the unit.

4. Check the oil level of all compressors, and pull the compressor pulley by hand to understand if it rotates freely.

5. Turn on the power of all equipment, start the motor, and observe whether the rotation direction of the motor is consistent with the indicator.

6. Disinfect the cold storage before the items are in.

7. Check the circuits and meters of all equipment for breakage and abnormal conditions.

8. Regularly check the humidity in the cold storage, and humidify when it is insufficient.

9. Observe whether the operating sound, temperature, and pressure of the compressors are normal.

10. Emergency power supply is required for cold storage in areas with frequent power outages.

11. Regularly ventilate the cold storage (turn on the ventilation fan) and defrost the evaporator (automatically defrosting device).

Conclusion

The above are the main points about building beer cold storage. When you build cold storage, you need to pay more attention, which will definitely save you money and achieve a better income.

Any comments?

Welcome leave a message or repost.