As the main driving equipment of all kinds of rotating machinery, motors are widely used in various fields of industrial production. Dozens or even hundreds of drive and control motors are often needed for large equipment or a production line. Even if only one of the motors fails, it will lead to the failure of the whole equipment, system or production line.

Meanwhile, modern large-scale production places special emphasis on continuity, requiring the reliable and uninterrupted operation of complete sets of equipment. Due to the interruption of equipment operation, even if it is only a few hours, the loss can be as high as hundreds of thousands, millions, or even more US dollars,seriously may cause complete sets of equipment scrapped.

Therefore, the safe and reliable continuous operation of the matching motor is crucial.

Let us understand the various faults of the motor below.

Motor Failure And Cause

Temperature Abnormal

The main heating components of motor are generally windings and bearings, specific to the appearance of temperature anomalies are generally divided into the following categories: bearing temperature is too high, winding temperature is too high, housing temperature is too high, and so on.

Let’s explain them one by one.

1. Bearing temperature is too high

Motor bearing is the main component of the supporting rotor, if the temperature is too high, will lead to loss of the motor bearing, efficiency will become lower, even causing the motor bearing to bite to death, and stall suddenly, finally bring the damage to the whole system.

Therefore, it is very important to monitor the condition of motor bearings.

Reasons of excessive bearing temperature:

1.1) Excessive bearing wear

Mechanical parts are bound to wear out during long-term operation, and the normal running motor should replace the bearing every few years.

After excessive wear, the bearing will produce a series of phenomena, such as high bearing temperature, larger bearing vibration, abnormal bearing noise, and so on.

1.2) Lack of oil

Grease will be added to lubricate the bearing. In the normal operation, the grease of motor bearing will gradually wear out. When the grease loss is too large, it will cause poor lubrication, resulting in a significant increase in motor-bearing temperature.

When found the bearing temperature is too high, you should stop to check the bearing condition of the motor immediately.

Motor Bearing

1.3) Other

As an integral part of the motor, the high temperature of each part probably will be transmitted to bearing and cause the bearing temperature excessively high.

Therefore, when you found the bearing is not abnormal, check each part of the motor near around bearing, perhaps you will find the source of abnormal temperature.

2. Winding temperature is too high

As an important part of the conversion of electrical energy to mechanical energy, state monitoring of motor windings is very important.

Through the monitoring, can reflect many problems, such as excessive load, winding insulation damage, abnormal load end, etc, all will lead to excessive winding temperature.

Reasons for excessive winding temperature:

2.1) Abnormal load

Before purchasing the motor, you must choose a suitable motor according to your used scenes.

The sudden change of the load during operation will lead to a significant change in the motor winding temperature.

2.2) Abnormal heat dissipation

During the motor on operation, will cause all kinds of losses, in which the stator&rotor losses are mainly reflected in the winding temperature.

When the winding temperature is too high, you can check whether the air inlet or outlet of the motor is blocked by dirt, whether the heat dissipation rib is damaged, and so on.

2.3) Winding aging

Internal temperature of the motor in normal operation is generally high, and there are harmonic problems for the motor powered by an inverter, which will lead to the aging of windings, magnets, and other components.

When the aging reaches a certain degree, will cause the decline of the motor performance, and the motor will change from normal operation to overload operation, meanwhile the winding temperature will rise significantly.

Generally speaking, the change of winding temperature caused by this kind of problem is relatively slow, and isn’t easy to cause a sudden rise in temperature.

3. Housing temperature is too high

For larger motors, will pre-embed temperature monitoring equipment to monitor the bearings or windings of motors.

But for smaller motors, sometimes this method is not easy to achieve.

Staff can use non-contact temperature measurement method to inspect the motor instead of the pre-embedded method.

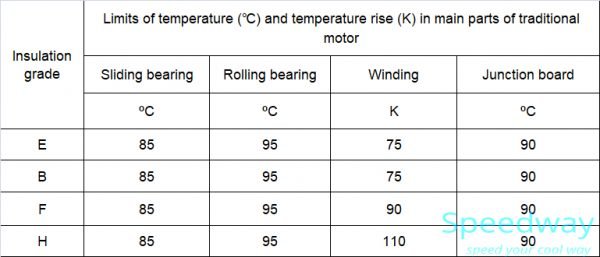

Temperature limit of each part of motor

As above, in the common use of motor, many faults will lead to abnormal temperature. Therefore, temperature monitoring is very important in the practical use of the motor.

The international standard stipulates the temperature of the main parts of the motor in safe use.

Limit of Temperature

Abnormal Noise and Vibration

A motor will inevitably produce noise and vibration in the process of use, especially when the mechanical structure of the motor is abnormal, and the abnormal phenomenon is the significant increase of noise or vibration.

Therefore, the monitoring of noise and vibration can early warn the fault of the motor, so as not to cause greater harm.

1. Excessive vibration

As an important technical index of motor, vibration is one of the main items in the type test of all kinds of motors.

When the mechanical parts are loosened, it will produce obvious vibration, such as excessive bearing wear will lead to the vibration of the extended side of the motor shaft, and the increase of vibration is a vicious process.

There are many reasons for the increase of motor vibration, such as the damage of mechanical structure, the aging of electrical structure, and the installation itself.

From the point of view of monitoring, it is divided into numerical abnormalities of vibration in various parts, which are mainly divided into 3 types: abnormal vibration of front cover, rear cover and machine base.

1.1) Abnormal vibration of the front cover

For the long-running motor, bearing is a mechanical component which is easy to aging.

When the bearing is worn, the end cover side of the motor may have an obvious vibration increase. In addition, the problem of the motor shaft may also cause abnormal vibration on the end cover side.

When the motor is in the manufacturing process or used improperly, after the long-term operation, probably cause abnormal vibration on the end cover side.

1.2) Abnormal vibration of the rear cover

Most motors are equipped with fans for heat dissipation on the non-shaft side. When the fan is damaged, the vibration will obviously increase on the back cover side of the motor.

If the fan is in good condition, you should check whether the rear bearing of the motor is abnormal.

1.3) Abnormal vibration of the machine base

Base as the main body of the motor, all kinds of vibration will convey to it. When you found the overall vibration of motor becomes larger, firstly you should ensure each installation fastener is loose or deformed.

When the fastening parts (installed on the outside of the motor) and the fastening parts of motor body are not loose, you should disassemble to confirm whether the internal components of the motor are loose.

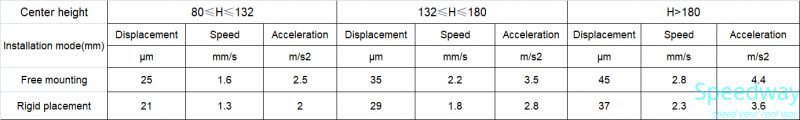

Motor Vibration Limit

2. Excessive noise

Motor noise is mainly divided into mechanical noise and electromagnetic noise.

Compared with the abnormal vibration of the motor, the sharp increase in noise is easier to be detected, but also easier to attract attention.

Excessive electromagnetic noise means problems in motor winding coils, while excessive mechanical noise means loosening or even fracture of mechanical parts.

Therefore, should check the motor timely when there is abnormal noise to avoid more serious noise accidents.

How to distinguish between electromagnetic noise and mechanical noise? When cutting the power supply of the motor ( the speed of the motor decreases slowly): If the noise still exists, it is mechanical noise; If the noise disappears immediately, generally is electromagnetic noise.

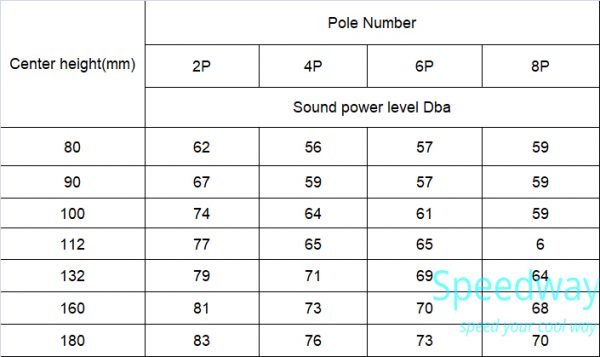

Because of many interference factors and great difficulties in the real-time monitoring and early warning of noise, generally test the noise of the motor under no-load conditions so as to analyze the possible problems of the motor.

Normal Motor Noise Limit

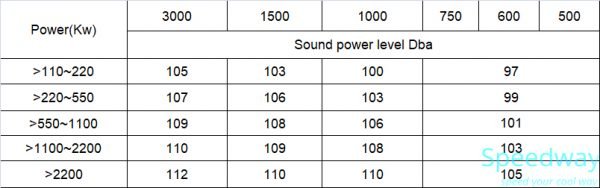

High-voltage Motor Noise Limit

Abnormal Electrical Parameters

As a kind of electrical equipment, the electrical parameter is a basic performance parameter. From the power consumption of the motor, it can reflect not only the running state of the motor itself but also the working state of the load end.

Current monitoring and voltage monitoring are commonly used in electrical parameter monitoring.

1. Excessive voltage deviation

1.1) When the motor is under-voltage, generally two kinds of reasons: one is power supply problem, the other is load problem.

The simultaneous operation of too many devices or the short-term overload operation of the current motor leads to overload and under-voltage phenomenon and most motors have a working voltage range.

The working voltage should be kept within this range as far as possible, see the nameplate of motor:

Motor Nameplate

1.2) When the motor is overvoltage, plan the downtime is very important.

In the power system with multiple electrical equipments working at the same time, if multiple devices stop working probably cause a sharp increase in power supply voltage.

1.3) When the motor is out of phase, must stop immediately and cut off the power supply circuit for troubleshooting. Generally, check first the transmission circuit then the power supply. If both of them are working normally, the problem perhaps occurs on the connecting parts of the two.

2. Current deviation is too large

Current value can truly reflect the use of electrical equipment, generally have the following types of abnormal current deviation.

2.1) Excessive current

Firstly, when found motor current exceeds the limit value, should check if the power supply is undervoltage or overvoltage.

Secondly, when there is a problem with the insulation of the motor, will lead to the phase-to-phase short circuit or to the ground short circuit of the motor, which will also lead to the occurrence of the over-current.

2.2) The current is too small

When the connection between motor and load is loosened, the current will obviously become smaller.

At this point, you should confirm whether there is any loosening of the connecting parts the integrity of the connection (between the motor and the load), such as shaft coupling loosening, tooth scratching, and so on.

Meanwhile, you should also check whether the load is in good working condition.

2.3) The current deviation is too large

There are generally 3 reasons for current value deviation:

1. Power supply problem

The imbalance of the supply voltage will directly lead to the imbalance of the motor current. Maintain power supply to solve this problem.

2. Aging of the windings

After long-term operation, the motor windings may be aging, resulting in changes in the value of the windings and the generation of current imbalance.

Stopping the machine, checking the turn-to-turn and winding resistance.

3. Windings insulation problem

In this problem, the current of a certain phase or several phases of motor will increase obviously, so you should stop immediately to check the phase-to-phase insulation and ground insulation of the windings.

Conclusion

Above is a summary of the most common problems of motors.

If you understand them all, then you can find the problem by yourself and find a suitable solution at the first time when your motor has an issue.

If the problem is really a headache, had better consult a service and maintenance company or the motor distributor, but it will definitely cost money.

Any comments?

Welcome leave a message or repost.