Before building cold storage, many people will consult related issues in cold storage construction and design. In fact, knowing some cold storage design and construction knowledge in advance is very helpful for the final cold storage plan; especially a good design plan is related to construction costs, later use effects, and operating costs, finally will ultimately affect your business profit.

How to Design a Cold Storage?

To design a cold room, you will need to consider the following factors:

Size

Determine the size of the Cold Room based on your storage needs and available space. Consider the number of perishable items you plan to store and how much space they will require.

Temperature Range

Determine the temperature range you need for your cold room. This will depend on the types of items you plan to store. For example, vegetables may require a temperature range of 0-5°C, while meat may require a range of -18 to -20°C.

Insulation

Choose the right type of insulation for your cold room. This will help maintain the desired temperature and prevent air leaks. Common insulation materials include polyurethane foam, polystyrene, and mineral wool.

Refrigeration System

Choose a refrigeration system that is appropriate for the size and temperature range of your cold room. Common types of refrigeration systems include split systems, packaged systems, and remote systems.

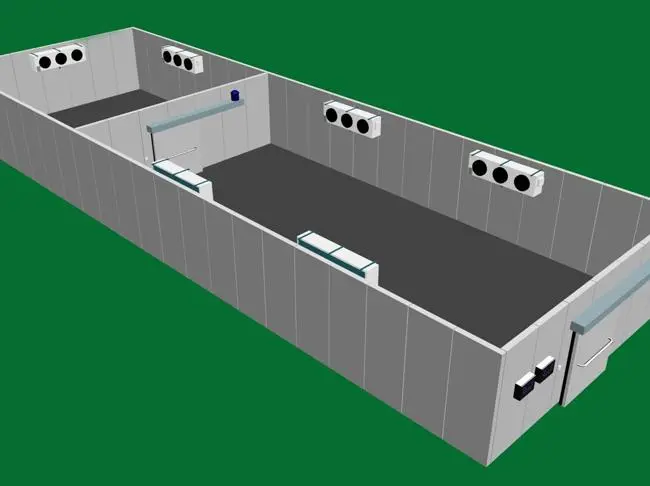

Cold Storage Design

Lighting

Install lighting in your cold room to improve visibility and make it easier to find items. Consider using LED lights, as they produce less heat and are more energy-efficient.

Ventilation

Proper ventilation is important to ensure good air circulation and prevent the buildup of moisture. This can be achieved through the installation of air vents or fans.

Flooring

Choose a flooring material that is durable, easy to clean, and can withstand low temperatures. Common options for cold room flooring include vinyl, epoxy coatings, and concrete.

Monitoring

Need to install temperature sensors and data loggers to monitor temperature and humidity levels. This helps identify temperature deviations and prevent product spoilage.

Air Curtain

Air curtains can be installed at the entrance of the cold room to reduce temperature fluctuations when the door is opened and closed.

Shelving and Storage

Install shelving and storage options that are appropriate for the size and weight of the items you plan to store. Consider using wire shelving as it allows for better air circulation and is easy to clean.

Cold Storage Shelving

Backup Power Source

It’s important to consider a backup power source for your cold room. This will help ensure that your perishable items remain at the desired temperature in case of a power outage.

Maintenance

Regular maintenance of your cold room is essential to ensure that it continues to function properly. This includes cleaning the interior, checking the temperature, and inspecting the seals on the door and panels for any signs of wear and tear.

Walk in Freezer Installation

How to Build a Cold Storage?

Building a cold room can be a great addition to your home or business, as it provides a convenient way to store perishable items at a constant and suitable temperature.

Build Cold Storage Checklists

Usage

Is it for self-use, rental, or logistics cold storage for turnover? There are many types of cold storage, and the design schemes of different types of cold storage are different.

Storage Items and Volume

What products need to store? What is the volume of cold storage? What are the requirements for the cooling speed of cold storage?

Different products require different storage temperatures, also refrigeration equipment is different; and blast freezer cold storage has certain requirements for the cooling speed.

For example, it takes 30 minutes for the processed product to reach the required temperature in the cold storage, if the goods in and out of the cold storage are frequently, needs a big cooling capacity unit to ensure product quality, and it must be selected according to the actual production situation.

Should design the cold storage volume according to the maximum amount of stored products, then can determine the cold storage size.

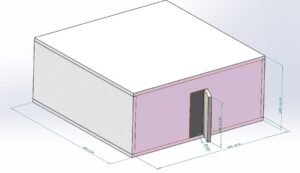

Cold Storage Build

Structure

Cold storage is divided into single-layer cold storage and double-layer cold storage, usually single-layer cold storage is a reinforced concrete structure or steel structure, and height is >7m.

Feature: High cargo handling efficiency, simple construction process, and low construction cost.

The double-layer cold storage is usually a brick-concrete structure or a reinforced concrete structure, height is >5 m, and the total height doesn’t exceed 20 meters.

Feature: Smaller size, reduce cost and save insulation materials.

Refrigeration Unit

Compressor is the core of the entire refrigeration system. Cold storage Refrigeration Units are divided into semi-hermetic and hermetic; rotary, piston, and scroll compressors.

The model and quantity of the refrigeration unit are configured according to the cold storage volume, temperature, stored items, and other specific parameters. There are different brands of refrigeration units such as imported, domestic, and joint ventured.

The condensation methods of refrigeration equipment are divided into air cooling, water cooling, and evaporative cooling, etc., which must be selected and installed according to the different conditions.

Refrigeration unit

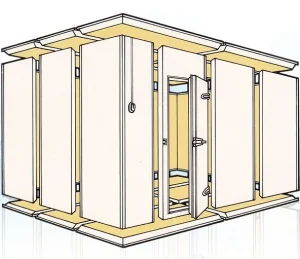

Insulation Panel

Cold storage Insulation Panels must not only have good heat insulation performance but also be economical and practical.

For example, the assembled cold storage can be assembled on-site, and is convenient, fast, and movable; while the spraying cold storage is fixed, can’t move at all, but can be customized in any size and shape.

You can choose different insulation materials and thicknesses, please contact our staff, and they will give you the most suitable choice.

Electric Control System

The electric control system included: electric control boxes, electric doors, lighting, etc., which can be controlled automatically without manual operation.

For example, refrigeration equipment automatic operation, automatic increase and decrease load, automatic control temperature and humidity, automatic recording and printing, automatic liquid supply, automatic defrosting, automatic fault alarm and analysis, automatic control of condensing pressure, etc.

Can be customized according to your needs.

Door

Select the Cold Storage Door according to the path width. Cold storage doors included: sliding door, electric door, rolling door, spring door, etc.

Skilled Person

Building cold room requires specialized knowledge and expertise.

It is very important to work with experienced professionals who can design, install, and maintain the cold room to ensure optimal performance and longevity.

Contact our person for professional support.

Materials Needed

– Insulated panels

– Angle bars

– Screws and bolts

– Hinges

– Door handle

Build Steps

Choose Location

The first step is to choose a location for your cold room. It should be an area that is easy to access and has enough space for the size of the room you want to build.

Build Frame

Using the angle bars, build a frame for the cold room. Ensure that the frame is sturdy enough to support the weight of the panels.

Install Panel

Secure the insulated panels to the frame using screws and bolts. Ensure that the panels are properly sealed to prevent any air leaks.

Cold Storage Panel

Install the Door

Attach hinges to the frame and install the door handle onto the door. Hang the door on the hinges and ensure that it closes properly.

Test the Temperature

Once the cold room is complete, test the temperature using a thermometer. Adjust the temperature as needed.

And that’s how you can build cold storage!

With the right materials and some basic construction skills, you can create a convenient space for storing perishable items.

Conclusion

By following the above, you can design, build and maintain cold storage that is both functional and efficient. It’s a great investment for anyone looking to store perishable items for an extended period of time.

Any comments?

Welcome leave a message or repost.