Copper tubes are called the “blood vessels” of air conditioner. Quality of the “blood vessels” will directly determine the quality of air conditioner. Today we will discuss how to weld refrigeration unit and air conditioning copper tubes.

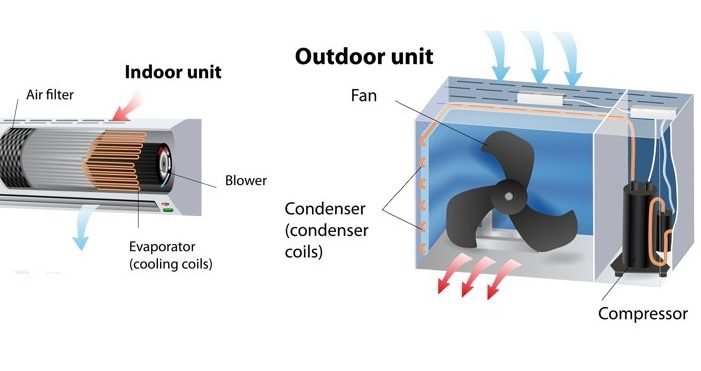

Air Conditioner Main Components

Air conditioner included indoor unit (evaporator) and outdoor unit (condenser).

Main components:

Compressor: Keep the refrigerant in the compressor at a high temperature and high pressure, liquefy the refrigerant, then circulate the refrigerant in the pipeline. There is oil in the compressor, the function of which is to lubricate the reciprocating motion of compressor, reduce friction, finally cool the system.

Filter: Filter impurity and dry moisture

Heat exchanger: Cool refrigerant

Four-way valve: Conversion of cooling and heating

Pipeline system: Pipeline for refrigerant circulation

Valve plate: Switch connected to indoor unit

Electronic expansion valve: Control refrigerant flow

More details about the components, please check page: “Refrigeration Accessory”

Welding Tips

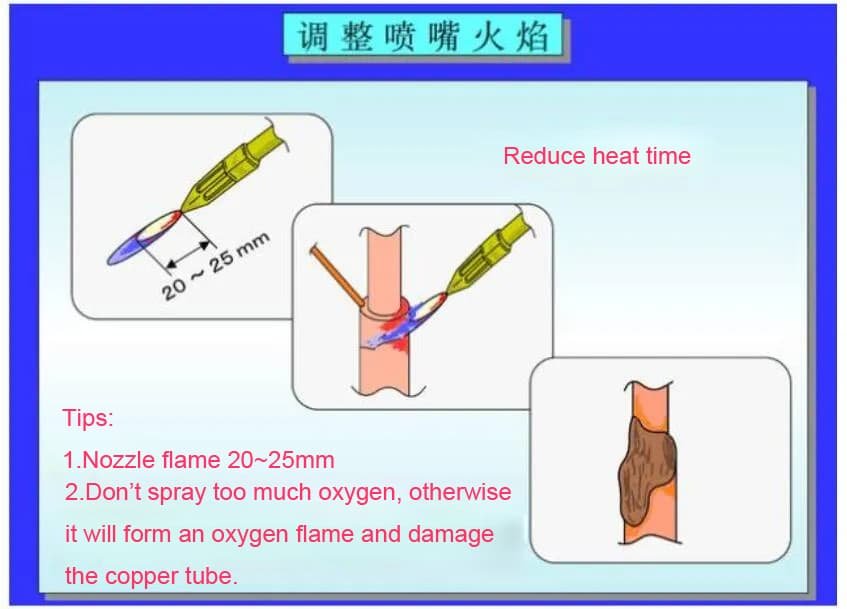

1. Heating

-Heat the copper tube until tube color reaches 740~840℃ (by visual sensation).

-Record the temperature at which copper tube will melt (holes appear) : 1,038℃.

-Maintain the welding temperature (740~840℃) for 10 seconds.

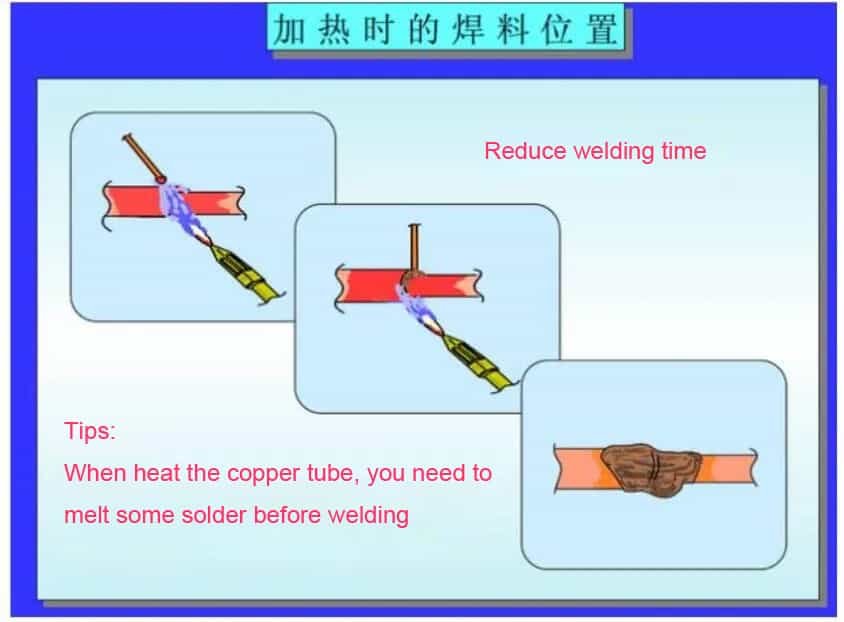

2. Fill Solder

-Use 1.6mm×0% solder

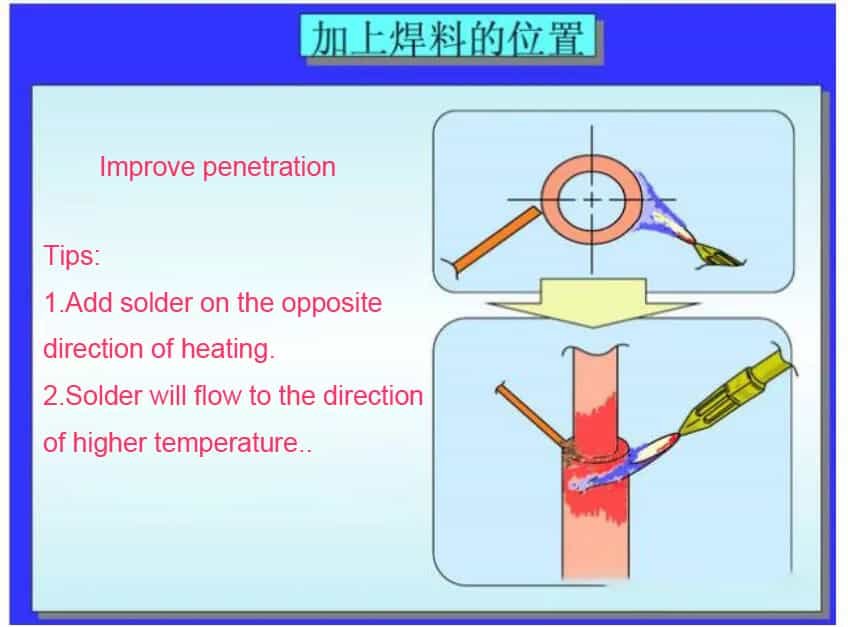

-Position for adding solder (opposite of heating)

-Timing for adding solder

-Dripping of solder (caused by temperature difference)

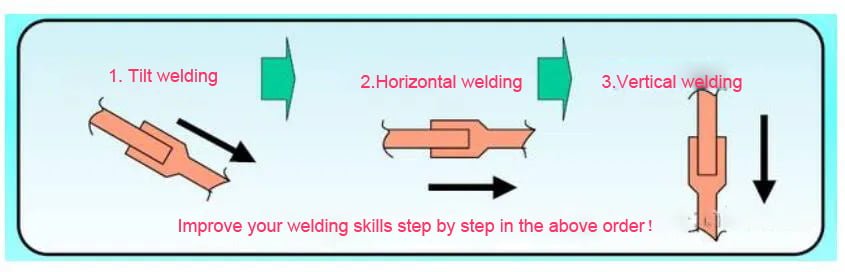

3. Welding Steps

| Type | Ag% |

|---|---|

| BCUP-3 | 5% |

| BCUP5 | 15% |

| BCUP6 | 2% |

| BAg30CuZn | 30% |

Welding Rod Types

Welding Operation

1. Adjust Nozzle Flame

2. Solder Location

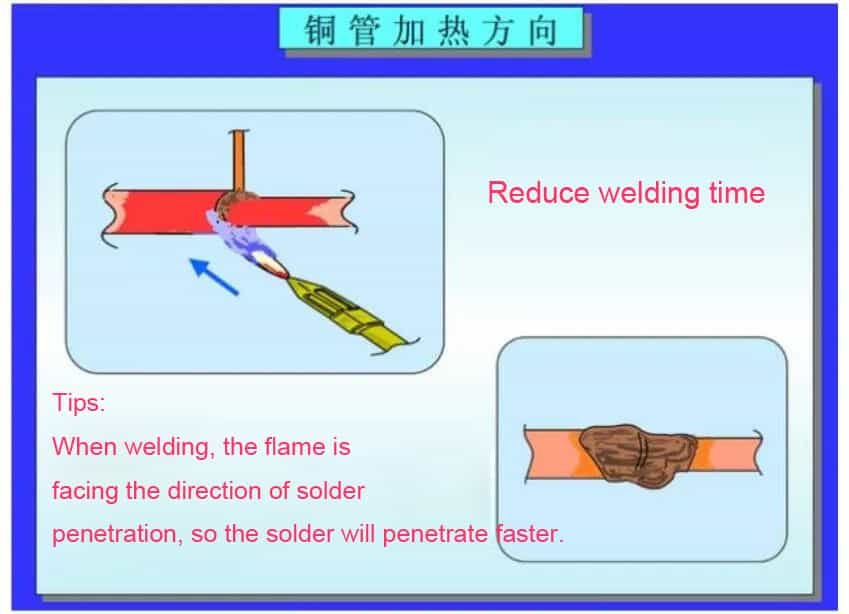

3. Copper Tube Heat Direction

4. Add Solder

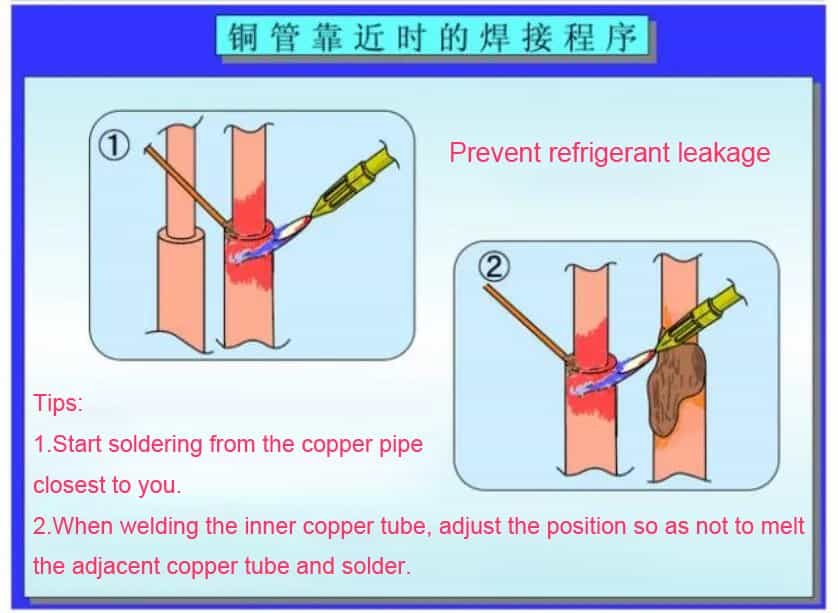

5. Multi Copper Tube Welding

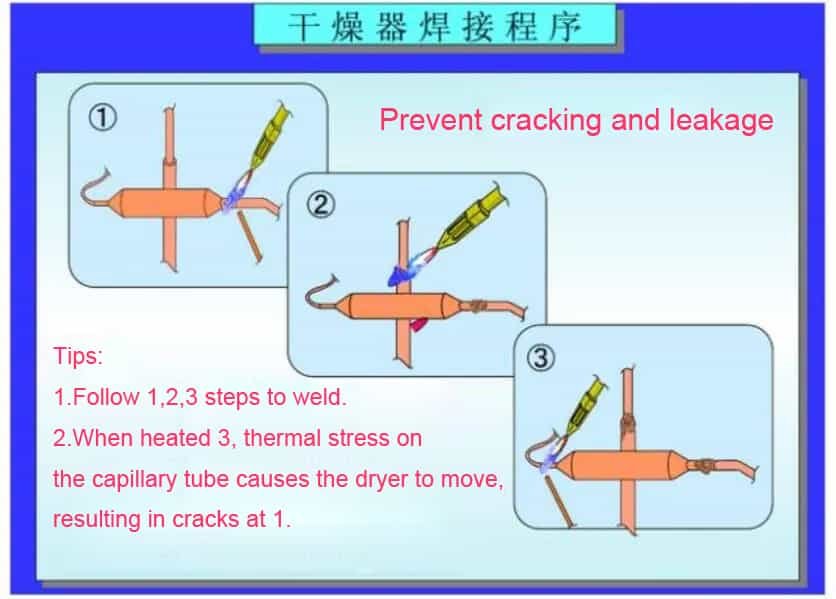

6. Dryer Welding

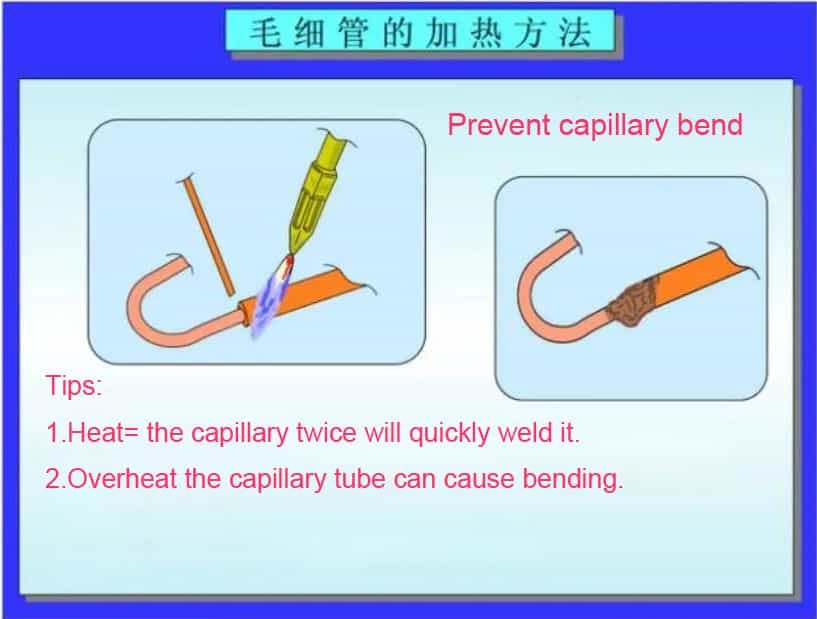

7. Heat Capillary

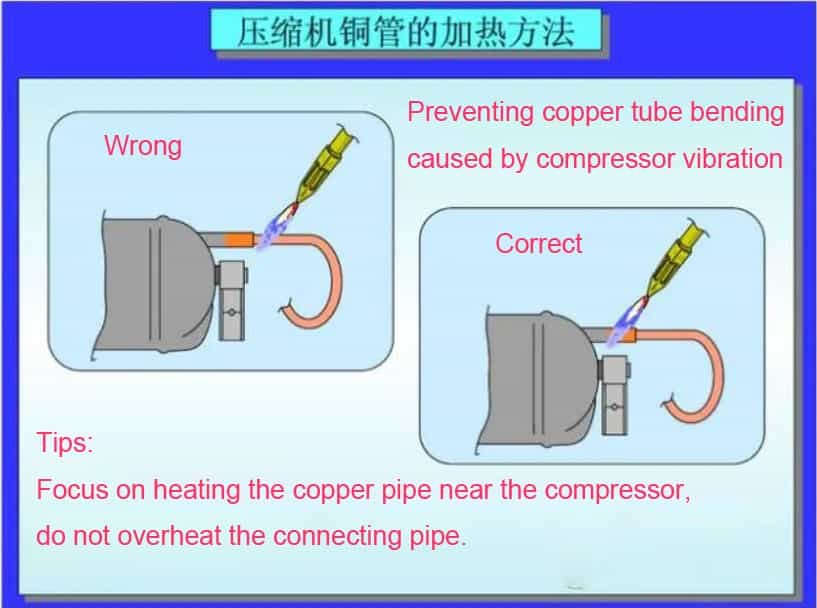

8. Compressor Tube Heating

Welding Quality Check

Check whether the welding parts’ sealing is good. Add refrigerant or nitrogen then stabilize for a while, and can use soapy water to check if the welding is absolutely leak-free.

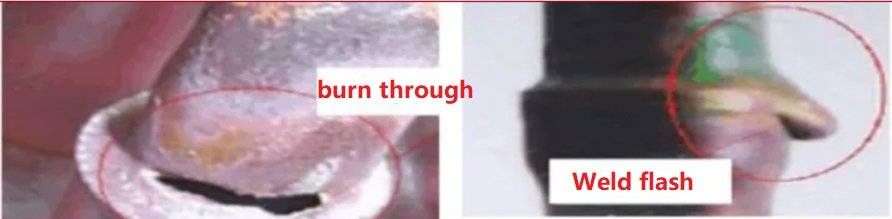

Unqualified welding

When air conditioner is running, the welds shouldn’t be cracked (seam) due to vibration. Debris shouldn’t block the pipes during welding, nor allow moisture enter due to improper operation.

The surface of the welded parts should be clean and free of oil stains.

Conclusion

In a word, welding copper pipe for air conditioners requires careful preparation, precise operation, and thorough post-welding checks to ensure a secure and efficient connection.

By following proper welding tips, execute the process with attention to detail, and verify the results, you can achieve reliable and long-lasting performance for your air conditioning system.

Any comments?

Welcome leave a message or repost.