At CHINA SPEEDWAY, we provide tailored refrigeration products solutions for our clients. This month we have client buying cold room refrigeration unit, worked for a cold room project in very hot country (in summer). You know, the refrigeration unit used in normal area and super hot area has very different design and configuration.

In this article, we will show you the actual example how did we work in the super high ambient temperature cold room project and keep products fresh, frozen and durable, so as a reference for customers who has the similar condition.

Clients specifications

Clients need to accurately control the cold room temperture ( in a large temperature scope) to keep the goods fresh, here are the details about this cold room project.

Country: Saudi Arabia

Ambient Temperature: Maximum 40~50°C ( Maximum 60 days for total in summer, each day 8 hours)

Cold room size: 7 x 4 x 3m (length x width x height)

Cold room application: Store foods ( fresh and frozen)

Cold room set temperature: +5 ~-25°C (large temperature scope in this super high ambient temperature area)

Inverter condensing unit location: Outside the cold room

Evaporator unit location: Inside the cold room

Cold room location: Resenditial area

Basic Solution

Inverter Condensing unit (outdoor unit): 7HP (Horsepower), 380V, 3phase 50Hz, R404 refrigerant. As in summer max ambient temperature is 40~50°C, and last 60 days for maximum. So have to use bigger size condenser (use 9HP condenser but not 7HP condenser), also need a shelder to lower the temperature for condensing unit.

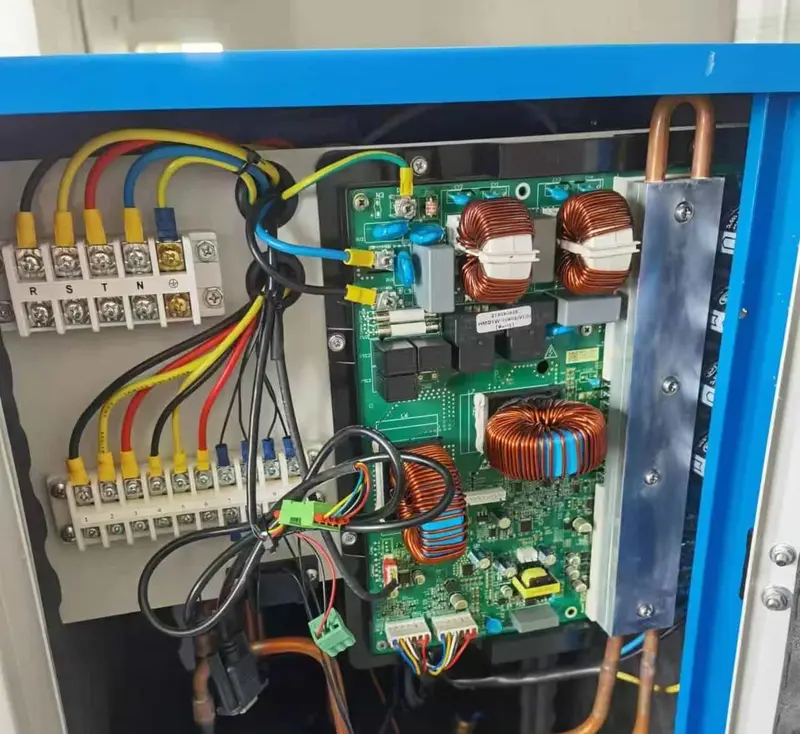

Inverter Condensing Unit Motherboard

Meanwhile, use inverter type condensing unit can save 50% electricity FOREVER, which can save lots of money for you.

Evaporator unit (indoor unit): 8HP, 380V 3 phase 50Hz with electric defrosting function

Cold room panel: 150mm thickness PU sandwich panel with 0.35mm galvanized steel

Cold room door: 150mm thickness PU sandwich panel with 10cm height threshold ( for better airtightness), cold room size–2.0×0.9m (height x width). Notice: You also can choose 100mm thickness door, but airtightness is not good as 150mm thickess.

Backup power: Use 25kva diesel generator to avoid any sudden outage, which will spoil your goods at all.

Diesel Generator

Specific Solution

1. Use large size condenser: Large condenser can sharply increase the cooling air volume, which can reduce the cold room temperature quicker.

2. Prepare a shelter for condensing unit ( outdoor unit), which can reduce its surface temperature.

Condensing Unit Shelter

3. Use a window balance with 220V 50HZ to balance room inside and outside pressure.

4. Use sealant to get better airtightness, because easily loss cooling air will affect your cold room cooling performance.

5. Prepare a plastic air stripe curtain for the cold room door to avoid any cooling air waste.

6. Use LED display screen board for inverter condensing unit to monitor the cold room temperature in REAL TIME.

LED Display Screen Board for Inverter Condensing Unit

7. Use one or two LED cold room light to keep the light clearly inside of the cold room.

8. Make a hole then install the floor drain on the floor panel, in order to clear and drainage all the waste water inside the cold room.

Need custom cold room solution?

At “CHINA SPEEDWAY”, we are experts in providing custom cold room solution for different applications.

Room temperature can be +15~-40°C (For some special condition can be -70°C), if you need another special temperature, can show us all requirements accordingly.

We will support you how to make specifically installation and provide drawings for cold room panel assembly, meanwhile give you all tips about cold room working properly and last longer lifetime.

Feel free to contact us for more details or to discuss your specific needs. We look forward to helping you optimize your systems with high-quality, precision-engineered cold room solutions.