In refrigeration industry, dry-bulb temperature and wet-bulb temperature are two crucial parameters. They not only influence the operational efficiency of air conditioning systems but also directly related to the comfort levels of our daily lives.

Dry-Bulb Temperature

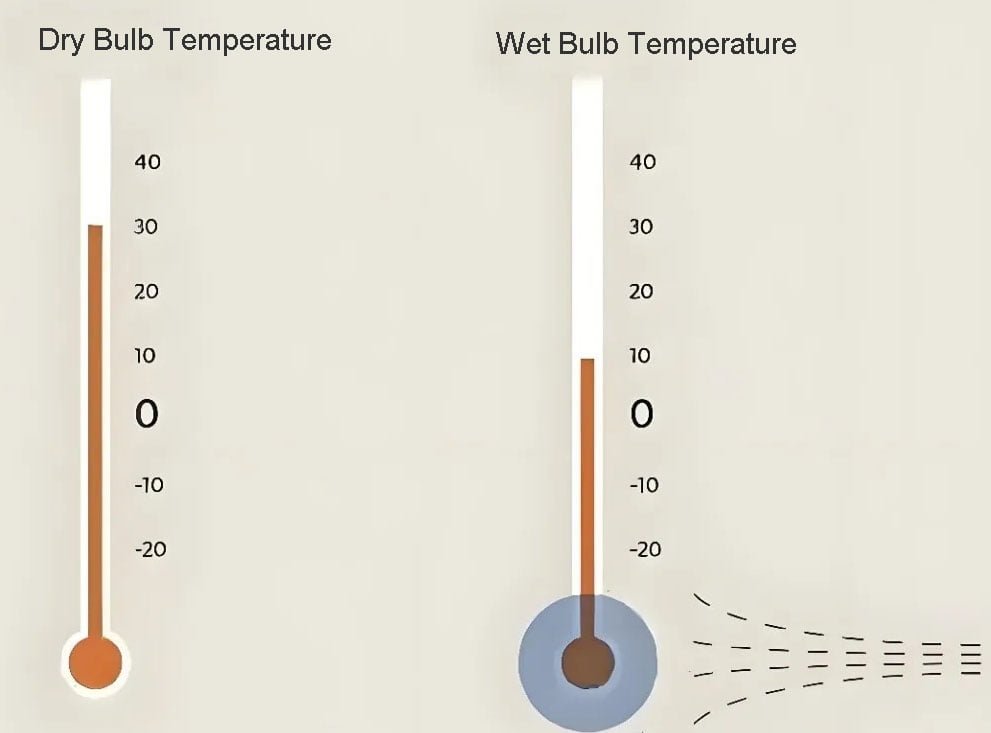

Dry-bulb temperature, is what we commonly refer to as air temperature. It’s the actual temperature of air. In refrigeration industry, dry-bulb temperature is a commonly used parameter in automatic control systems, employed to regulate valve openings, adjust indoor temperatures, and more.

Measurement of Dry-Bulb Temperature

The measurement of dry-bulb temperature is very simple:

–Expose the thermometer to the air.

–Avoid direct sunlight and interference from moisture to obtain an accurate reading.

Role of Dry-Bulb Temperature in Refrigeration Systems

Dry-bulb temperature impacts both our daily lives and the operation of refrigeration systems. For instance:

–During summer, indoor dry-bulb temperatures are set between 24°C~26°C to ensure a comfortable indoor environment.

—Air conditioning systems automatically adjust cooling functions based on the set dry-bulb temperature to maintain the desired conditions.

Wet-Bulb Temperature

Wet-bulb temperature means the lowest temperature air can reach under constant humidity conditions. It’s the temperature recorded when air passes over a wet fabric (saturated with water), causing the water to evaporate and absorb heat, thereby cooling the thermometer.

Measurement of Wet-Bulb Temperature

Measure wet-bulb temperature requires a special thermometer wrapped in a wet cloth:

–As water evaporates from the cloth, heat is absorbed, causing the thermometer to show a temperature lower than the dry-bulb temperature.

Characteristics of Wet-Bulb Temperature

–Wet-bulb temperature is closely linked to air humidity.

–When air is dry, water evaporates quickly, and the wet-bulb temperature is significantly lower than the dry-bulb temperature.

–When air is nearly saturated, evaporation slows, and the wet-bulb temperature approaches dry-bulb temperature.

Thus, wet-bulb temperature not only reflects air humidity levels but also helps assess the potential for evaporative cooling.

Applications in Refrigeration

1. Temperature Setting and Control

In air conditioning systems, dry-bulb temperature serves as the key reference for setting indoor temperature, while wet-bulb temperature is used to regulate indoor relative humidity. By measuring both, can calculate relative humidity and adjust systems to ensure an optimal indoor environment.

2. Evaluate Cooling Performance

The variations in dry-bulb and wet-bulb temperatures are indicators of air conditioning performance:

–The rate and extent of reduction in dry-bulb temperature reflect the cooling capacity of the air conditioner.

–Observe changes in wet-bulb temperature reveals the system’s dehumidification efficiency.

3. Cooling Tower Design and Operation

Wet-bulb temperature plays a vital role in cooling tower design:

–The principle of cooling towers relies on evaporative cooling, where heat is removed via water evaporation.

–Knowing the outdoor wet-bulb temperature helps determine the cooling tower’s minimum achievable temperature, enabling efficient design and operation strategy.

Dry-Bulb and Wet-Bulb Temperatures Measure and Influence

Dry-Bulb Temperature Measurement

Dry-bulb temperature measurement is simple, required only precautions against direct sunlight and moisture interference.

Wet-Bulb Temperature Measurement Considerations

Wind Speed: Wet-bulb temperature is significantly influenced by airspeed. Higher airflows enhance heat and moisture exchange, leading to more accurate readings.

Radiation: Avoid direct radiation during measurement to ensure accuracy.

Wet Cloth Condition: The choice of fabric, size, and saturation level of the wet cloth affects the measurement accuracy.

What is Dew Point Temperature?

Dew point temperature is not only a crucial measure of air humidity but also a key parameter in the design and operation of refrigeration equipment.

Dew point temperature refers to the temperature at which water vapor in the air begins to condense into water droplets. Under a given pressure, when moist air is cooled to the point where relative humidity reaches 100%, water vapor condenses into water droplets. At this temperature, the air is considered saturated, and condensation begins.

This principle relies on the relationship between saturated air’s moisture content and temperature: cooling unsaturated air to its dew point will cause condensation.

Relationship Between Dew Point Temperature and Refrigeration

1. Dew Point Temperature in Air Conditioning Systems

Dew point temperature is crucial for controlling indoor humidity.

–As air passes through condenser, some water vapor condenses into water droplets and is expelled, reducing air humidity.

–This process lowers the air’s dew point temperature, creating a comfortable environment.

2. Dew Point Temperature in Cold Room

In cold room, controlling dew point temperature prevents moisture from condensing on the surface of stored goods, thereby avoid spoilage or damage.

Dew Point Temperature Measure and Influence

Measurement of Dew Point Temperature

Use special dew point meters or hygrometers to measure dew point temperature. These instruments calculate dew point temperature based on relative humidity, air pressure, and temperature.

Factors Influence Dew Point Temperature

Air Pressure: Higher air pressure increases saturation vapor pressure and raises dew point temperature.

Air Temperature: Lower air temperatures decrease saturation vapor pressure, lead to a lower dew point temperature.

Air Moisture Content: Higher moisture content in the air results in a higher dew point temperature.

Instrument Accuracy: The precision of dew point meters significantly impacts measurement accuracy, provide reliable data for refrigeration systems.

Applications in Refrigeration

1. Dehumidification and Humidification

By controlling dew point temperature, refrigeration systems can either dehumidify or humidify air.

–Lower the dew point temperature enables dehumidification.

–Raise the dew point temperature facilitates humidification.

2. Energy Efficiency and Optimization

Accurate control of dew point temperature helps achieve energy-efficient operation of refrigeration systems, minimize overcooling and unnecessary energy consumption.

3. Equipment Selection and Design

Dew point temperature is a key factor in selecting and design refrigeration equipment to meet specific environmental and operational requirements.

Relationship among Dry-Bulb, Wet-Bulb, and Dew Point Temperatures

1. Dry-Bulb vs. Wet-Bulb Temperatures

–Dry-bulb temperature is always greater than or equal to wet-bulb temperature.

–The difference between the two (dry-bulb-wet-bulb temperature difference) reflects relative humidity: a larger difference indicates drier air, while a smaller difference indicates near-saturated air.

2. Dry-Bulb vs. Dew Point Temperatures

–Dry-bulb temperature is always greater than or equal to the dew point temperature.

–The difference between the two indicates the air’s moisture state: a larger difference signifies drier air, and a smaller difference indicates higher humidity.

3. Wet-Bulb vs. Dew Point Temperatures

–Wet-bulb temperature is higher than the dew point temperature unless the air is saturated, in which case the two are equal.

Conclusion

Dry-bulb, wet-bulb, and dew point temperatures are essential parameters in refrigeration systems, playing vital roles in temperature control, humidity regulation, and energy efficiency.

Simple Explanation as:

Dry bulb temperature: reflects air actual temperature and used to calculate the sensible heat load.

Wet bulb temperature: reflects air cooling limit and used to calculate the latent heat load and enthalpy value.

Dew point temperature: reflects the saturated state of water vapor in the air and used for dehumidification and humidity control.

Understanding their relationships and applications enables better system performance, improve comfort, and optimize energy use, making them indispensable in both industrial and daily life.

Any comments?

Welcome leave a message or repost.