In the world of HVACR (Heating, Ventilation, Air Conditioning, and Refrigeration) systems, refrigerant distributor plays a crucial yet often overlooked role. If you’re searching for “what is a refrigerant distributor,” “how does a refrigerant distributor work,” or “types of refrigerant distributors,” this guide covers everything you need to know.

Whether you’re an HVACR technician, engineer, or homeowner troubleshooting your AC unit, understanding the refrigerant distributor can optimize system efficiency, prevent costly breakdowns, and ensure even cooling.

We’ll break it down step by step, from basics to advanced troubleshooting.

Introduction to Refrigerant Distributor

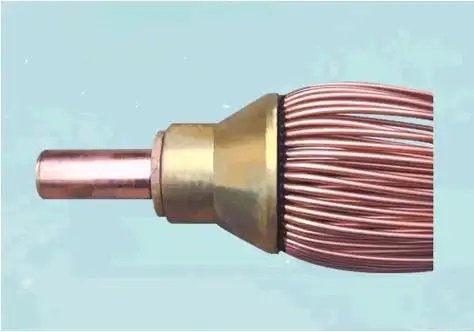

Refrigerant distributor is a vital mechanical device in refrigeration and air conditioning systems, specifically used to evenly disperse liquid and vapor refrigerant across multiple parallel circuits in an evaporator coil.

Often likened to a “showerhead” for refrigerant, it ensures balanced flow, preventing hotspots or inefficiencies that could lead to uneven cooling or system strain.

In HVACR setups, the distributor sits between the thermostatic expansion valve (TXV) and the evaporator, handling saturated refrigerant (a mix of liquid and gas) to promote optimal heat absorption.

Why does this matter?

Poor distribution can cause coil freeze-up, reduced efficiency, or compressor damage.

For those querying “refrigerant distributor function,” it’s essentially the equalizer that maximizes energy transfer, improving overall system performance by up to 20~30% in multi-circuit evaporators. This guide demystifies it for beginners and pros alike.

History and Evolution of Refrigerant Distributors

The story of refrigerant distributor mirrors the broader evolution of refrigerants and HVACR tech, dating back to the late 19th century when mechanical refrigeration emerged. In 1876, German engineer Carl von Linde patented gas liquefaction processes, laying groundwork for modern systems. Early distributors were rudimentary, relying on simple manifolds without precise mixing.

By the 1920s, with the invention of chlorofluorocarbons (CFCs) by Thomas Midgley, distributors evolved to handle more volatile refrigerants like R12. The 1970s-1980s saw advancements amid environmental concerns, shifting from CFCs to HCFCs (e.g., R22). Distributors incorporated nozzles for better velocity control, addressing issues like uneven flow in larger coils.

Today, with the phase-out of R22 under the Montreal Protocol and rise of HFCs like R410a, R32, R404, etc. modern distributors feature interchangeable orifices and venturi designs for low-GWP (Global Warming Potential) refrigerants. Future trends point to eco-friendly adaptations for CO2-based systems, emphasizing sustainability in HVACR evolution.

How a Refrigerant Distributor Works

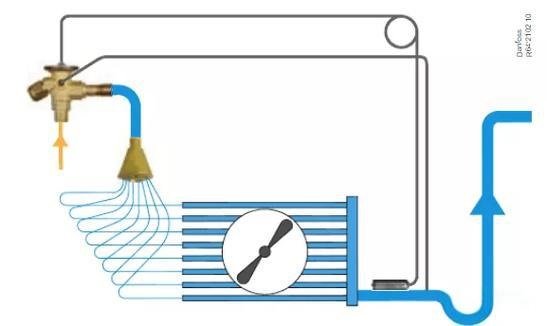

Understanding “how a refrigerant distributor works” starts with its placement in the refrigeration cycle. After the TXV meters refrigerant into the distributor, the device uses nozzle to accelerate the flow, creating a pressure drop that mixes liquid and vapor phases homogeneously.

This high-velocity mixture then branches into capillary tubes or circuits, ensuring even evaporation across the coil.

Key steps in operation:

- Inlet Phase: Saturated refrigerant enters from the TXV at moderate pressure.

- Mixing Chamber: Internal baffles or venturi effects agitate the refrigerant, achieving 50-70% vapor quality for uniform distribution.

- Outlet Distribution: Tubes feed the evaporator, where refrigerant absorbs heat, turning to vapor before returning to the compressor.

- Pressure Dynamics: Proper sizing maintains a 5-10 psi drop, preventing stratification (liquid pooling).

In multi-circuit evaporators, this prevents “mal-distribution,” where some sections overfeed while others starve, leading to inefficiencies. For visual learners, imagine it as a traffic cop directing refrigerant “cars” to avoid jams.

Types of Refrigerant Distributors

Not all refrigerant distributors are created equal—selection depends on system size, refrigerant type, and evaporator design. Here’s a breakdown of common types:

| Type | Description | Best For | Key Features |

|---|---|---|---|

| Nozzle | Uses interchangeable orifices to control flow; resembles a perforated cap | Flexible applications like commercial AC units | Adjustable sizing, easy retrofits; handles R-410A well |

| Venturi-Flo | One-piece unit with venturi nozzle for natural mixing via velocity increase | High-capacity systems | No loose parts, reduces clogging; ideal for R-134a |

| RD (Liquid Distributor) | Danfoss-style with uniform branching for multi-section evaporators | Industrial refrigeration | Compatible with R-404A, R-407C; ensures low void fractions |

| Flange Inlet (e.g., Types 1109/1124) | Bolts directly to TXV outlet with male flange | Sporlan-integrated systems | Compact, vibration-resistant; for smaller residential units |

| Orifice Distributors | Basic showerhead-like design with fixed holes | Budget setups | Simple, cost-effective; common in older R-22 systems |

Choose based on refrigerant (e.g., R410a needs higher pressure tolerance) and circuit count—up to 12 for large coils.

Importance in HVACR Systems

Refrigerant distributor is non-negotiable for efficiency in modern HVACR. It promotes uniform heat transfer, reducing energy use by ensuring every coil section evaporates refrigerant optimally. Without it, systems suffer:

- Uneven Cooling: Hot/cold spots in rooms.

- Compressor Overload: Floodback from imbalanced flow.

- Efficiency Losses: Up to 15% higher energy bills.

In commercial settings, it extends equipment life by minimizing thermal stress. For eco-conscious searches like “refrigerant distributor energy savings,” note it supports low-GWP transitions, aligning with EPA regulations.

Installation Guide for Refrigerant Distributors

Proper refrigerant distributor installation is critical to avoid leaks or restrictions. Always follow manufacturer specs (e.g., Parker Sporlan guidelines). Tools needed: torque wrench, flux, brazing torch.

Step-by-step:

- Prep the System: Evacuate refrigerant; isolate the evaporator.

- Mount the Distributor: Position horizontally above the coil header, 6-12 inches from TXV. Secure with clamps.

- Connect Inlet: Braze or bolt to TXV outlet; use ASC (Automatic Distributor Selector) if needed for nozzle retention.

- Attach Outlet Tubes: Cut to length (match coil circuits); flare ends and connect with unions. Ensure equal lengths for balance.

- Insulate and Test: Wrap with foam; pressure-test at 300 psi, then leak-check with nitrogen.

- Charge and Commission: Add refrigerant; monitor superheat (8-12°F target).

Pro Tip: For R410a, use longer tubes for better mixing. Consult local codes for safety.

Maintenance Tips for Longer Life

Regular refrigerant distributor maintenance prevents 80% of failures. Schedule bi-annual checks.

- Visual Inspection: Look for corrosion, loose fittings, or oil residue indicating leaks.

- Clean Orifices: Flush with solvent if clogged; avoid abrasives.

- Check Tubing: Ensure no kinks; replace if diameter-reduced.

- System-Wide Tune-Up: Verify TXV function and superheat; adjust distributor if flow imbalances detected.

- Refrigerant Purity: Use filters to prevent debris; change annually.

For “refrigerant distributor cleaning,” a simple nitrogen blow-through suffices for most types. This extends life to 10+ years.

Common Issues and Troubleshooting For Refrigerant Distributor

Troubleshooting refrigerant distributor issues often reveals restrictions or malfunctions.

Symptoms: Low suction pressure, coil freeze-up, or uneven temps.

| Issue | Causes | Troubleshooting |

|---|---|---|

| Uneven Distribution | Clogged nozzle or unequal tube lengths | Measure flows; resize orifices; equalize tubing |

| Freeze-Up | Low charge or restriction | Check superheat; thaw and recharge; inspect for debris |

| Leaks | Brazed joint failure | Braze repair or replace; use 45% silver solder |

| Poor Mixing | Worn venturi | Replace distributor; test velocity drop |

Use gauges: Aim for 5-10°F superheat. If persistent, call a pro to avoid compressor damage.

Conclusion

Mastering the refrigerant distributor unlocks efficient, reliable HVACR performance. From its venturi-driven mechanics to nozzle-type versatility, this component ensures your system runs smoothly.

Remember: Install correctly, maintain diligently, and troubleshoot proactively. As refrigerants evolve toward sustainability, distributors will adapt—stay informed via resources like ASHRAE.

For more on “refrigerant distributor best practices,” bookmark this guide.

Any comments?

Welcome leave a message or repost.