In the fast-paced world of logistics, food storage, and manufacturing, maintaining precise temperature control is crucial. Whether you’re running supermarket, warehouse, or a special facility, ensure cold storage areas remain efficient and effective is a constant challenge. One of the most practical yet often overlooked solutions to this problem is the use of cold room curtains.

What Are Cold Room Curtains?

Cold room curtains are flexible barriers made from materials like PVC , Mesh strip, PEVA, or insulated fabrics, used to regulate the temperature within cold storage areas such as freezers, chillers, or temperature-controlled rooms. These curtains are hung over doorways, entrances, or open areas to help maintain a stable internal temperature while allowing easy access for people and equipment.

Basic Function

- Temperature Control: Cold room curtains act as a barrier to minimize the exchange of warm and cold air when doors are open. This helps maintain the set low temperature inside the storage area, which is crucial for perishable goods storage.

- Energy Efficiency: By reducing the amount of cold air that escapes and warm air that enters, these curtains help lower energy consumption, and reduce operational costs.

- Passability: Cold room curtains allow people and vehicles, like forklifts, to pass through without fully open or close heavy doors, improving efficiency and workflow.

- Contamination Prevention: In addition to temperature control, these curtains can help prevent the entry of dust, insects, and other contaminants, contributing to a cleaner and more hygienic environment within the cold storage area.

Cold Room Curtains Classification

PVC Strip Curtain

Description:

- Made from flexible polyvinyl chloride (PVC) strips that overlap.

- Available in different thickness and width.

Application:

- Used in walk-in coolers and freezers.

- Suitable for areas with frequent pedestrian or vehicle traffic.

- Ideal for temperature-controlled environments which require easy access.

Insulated Curtain

Description:

- Made from insulated materials like foam or quilted fabric.

- Provide better thermal insulation compared to PVC strips.

Application:

- Used in cold room required stricter temperature control.

- Suitable for freezer rooms, blast freezers, and environments with low temperatures.

- Ideal for areas with less frequent access.

Polar Grade Curtain

Description:

- A special type PVC curtain used for extremely low temperatures (≤ -40°C).

- Made from special formulated materials to prevent brittleness in freezing conditions.

Application:

- Suitable for deep freeze environments like blast freezers.

- Commonly used in food processing plants and cold storage facilities handling sensitive products.

Anti-microbial Curtain

Description:

- PVC or fabric curtains treated with anti-microbial agents.

- Can prevent the growth of bacteria, mold, and fungi.

Application:

- Ideal for food processing areas, healthcare facilities, and environments with strict hygiene requirements.

- Suitable for cold storage areas storing perishable goods.

Hybrid Curtain

Description:

- Combines different materials (e.g., PVC and insulation) for multi-functional use.

- Will provide both flexibility and insulation.

Application:

- Suitable for cold storage areas required both temperature control and easy access.

- Common in large industrial cold room and logistics facilities.

PEVA Curtain

Description:

- PEVA (Polyethylene Vinyl Acetate) curtains are made from a non-chlorinated vinyl material which is an eco-friendly alternative to PVC.

- Free of harmful chemicals like chlorine and phthalates, making it a safer choice for various applications.

- It is a flexible, lightweight, and durable material that is often used in environments where both temperature control and hygiene are important.

Application:

- PEVA curtains are ideal for light-duty use where chemical safety and moisture resistance are key considerations, such as shower curtains, partitions, or basic barriers in cold storage.

- Such as hospital, clinic, and laboratory, can use PEVA curtains as partitions or barriers to maintain cleanliness and prevent the spread of contaminants.

Air Curtain

Description:

- Blows air stream across the doorway, creat an invisible barrier between cold room inside and outside.

- Maintain temperature control by preventing air exchange, whether it’s keeping cool air in room and warm air out, without the need for a physical barrier like a door.

Application:

- Used in commercial and industrial settings, such as cold rooms, supermarkets, and food processing facilities.

- Ideal for doorways with frequent traffic, helping to maintain internal temperatures, improve energy efficiency, and prevent the entry of contaminants like dust and insects.

How to Choose Right Cold Room Curtains?

Factors to Consider

Size

- Doorway Dimension: Measure width and height of the doorway or entrance where will install the curtains. Proper sizing is essential to ensure the curtains effectively cover the opening and minimize air leakage.

- Curtain Overlap: When choosing strip curtains, ensure that there is sufficient overlap between strips to prevent gaps, which can reduce the curtain’s effectiveness.

- Custom Fit: In some cases, you need custom-sized curtains to fit non-standard doorways or special equipment access points.

Material

- PVC: The most common material used for cold room curtains, PVC is flexible, durable, and resistant to low temperatures. PVC is ideal in areas with frequent traffic.

- Insulated Fabric: For environments that require strict temperature control, insulated curtains made from foam or quilted fabric provide superior thermal protection.

- Anti-microbial Coating: In food processing or healthcare environments, curtains with anti-microbial properties can help prevent the growth of bacteria and mold.

Thickness

- Standard Thickness: For general cold storage areas with moderate temperature differences, standard PVC curtains (usually 2~4mm thick) are sufficient.

- Heavy-Duty Thickness: In areas with extreme temperature differences or high traffic, thicker curtains (≥ 8mm) provide better insulation and durability.

- Insulated Layers: For maximum temperature control, consider insulated curtains with multiple layers or additional padding.

Installation

- Ease of Installation: Some curtains come with simple mounting hardware and can be easily installed by maintenance staff, while others may require professional installation by expert.

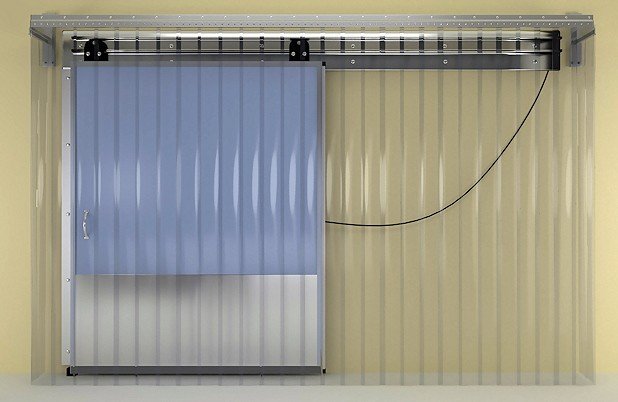

- Mounting Options: Consider how the curtains will be mounted. Options include wall-mounted, ceiling-mounted, or track systems that allow the curtains to slide open and closed.

- Accessibility: In high-traffic areas, ensure the installation doesn’t hinder movement. For example, PVC strip curtains allow easy passage, while insulated curtains require extra consideration for access points.

Matching Curtains to Specific Needs

High-Traffic Areas

- Durable PVC Strips: In areas with frequent movement of people or equipment, such as loading docks or walk-in coolers, choose durable PVC strip curtains that can withstand repeated use.

- Reinforced Edges: Look for curtains with reinforced edges to prevent wear and tear, especially in environments with heavy machinery or forklifts.

Extreme Temperatures

- Polar Grade Curtains: In environments with very low temperatures, such as blast freezers, polar-grade PVC curtains can remain flexible and effective in temperatures lower than -40°C.

- Insulated Curtains: For areas that need to maintain strict temperature control, insulated curtains offer superior protection against temperature fluctuations.

Hygiene-Sensitive Areas

- Anti-microbial Curtains: In food processing, healthcare, or pharmaceutical environments, anti-microbial curtains help prevent contamination and maintain strict hygiene standards.

Visibility and Safety

- Clear PVC Curtains: If visibility is crucial, such as in retail cold storage or areas with heavy foot traffic, clear PVC curtains allow staff to see through the barrier, reducing the risk of accidents.

- Color-Coded Strips: In some environments, color-coded curtains can help designate specific areas, improving organization and safety.

Considerations for Custom Solutions

Tailored Fit

- Custom Size: For non-standard doorways or unique access points, custom-sized curtains ensure a perfect fit, maximize efficiency and temperature control.

- Special Shapes: If you have irregularly shaped openings, custom solutions can accommodate these needs without reduce performance.

Dual-Purpose Curtains

- Combination Curtains: In some cases, you need curtains that serve multiple functions, such as providing insulation while allowing airflow. Combination curtains, such as mesh and PVC hybrids, can meet these specific needs.

Special Features

- Automated Systems: For high-tech facilities, consider curtains with automated opening and closing systems that respond to motion or temperature changes, improving convenience and efficiency.

- Heavy-Duty Mounts: In environments with large or heavy curtains, consider reinforced or motorized mounts to ensure stability and ease of use.

Cold Room Curtain Maintenance and Care Tips

Regular Clean

- Dust and Debris Removal: Dust, dirt, and debris can accumulate on cold room curtains over time, especially in high-traffic areas. Clean curtains regularly to prevent buildup can reduce their effectiveness. Use a damp cloth or a mild detergent to wipe down the curtains, ensuring that they remain clean and transparent.

- Prevent Ice Buildup: In cold environments, ice or frost can accumulate on the curtains, which can cause them to become stiff or damaged. Regularly check for ice buildup and remove it carefully to avoid tearing the material.

Inspect for Wear and Tear

- Check for Damage: Inspect the curtains for any signs of wear and tear, such as cracks, tears, or fraying edges. Damaged curtains can compromise the insulation and efficiency of your cold room. Replace any damaged sections promptly to maintain proper functionality.

- Inspect Fasteners: Ensure the curtain fasteners, such as hooks, brackets, or tracks, are securely in place. Loose or damaged fasteners can cause the curtains to sag or become misaligned, reducing their effectiveness.

Proper Handling

- Avoid Rough Handling: Train staff to handle the curtains carefully, especially when move equipment or goods through the doorways. Rough handling can lead to premature wear or damage to the curtains.

- Use in Moderation: Encourage staff to only open the curtains when necessary, minimize unnecessary exposure to temperature fluctuations and reduce the strain on the curtains.

Schedule Maintenance Check

- Routine Inspections: Schedule regular maintenance checks to assess the condition of the curtains and address any issues before they become major problems. This included: inspect both curtains and hardware which used to support them.

- Preventive Maintenance: Consider performing preventive maintenance tasks, such as lubricating tracks or hinges, to ensure smooth operation and reduce the likelihood of mechanical issues.

Monitor Performance

- Energy Efficiency: Keep an eye on your cold room’s energy consumption. If you notice a spike in energy usage, it may indicate that the curtains are no longer providing effective insulation, and need repair or replacement.

- Temperature Control: Regularly check the temperature inside the cold room. If the temperature is fluctuating more than usual, the curtains may not be sealing properly, and need adjustments.

Seasonal Adjustments

- Adapt to Conditions: Depend on the season, you should adjust the curtains to handle different temperature and humidity levels. For example, during warmer months, you need to clean or inspect the curtains more frequently to ensure they are effectively blocking warm air.

Keep Spare Parts Handy

- Have Replacements Ready: Keep spare parts, such as extra curtain strips or fasteners, on hand to quickly address any damage. This will minimize downtime and ensure that your cold room remains fully operational.

Conclusion

Cold storage curtains play a crucial role in maintaining temperature stability, energy efficiency, and overall operational effectiveness in cold rooms and refrigerated environments. Whether you choose strip curtains, air curtains, or insulated curtains, proper selection, installation, and maintenance are essential to maximize their benefits.

Investing in quality curtains and maintaining them diligently will not only help protect your products but also reduce energy costs and improve the efficiency of your cold storage facility.

Any comments?

Welcome leave a message or repost.