In the world of HVACR (Ogrzewanie, Wentylacja, Klimatyzacja, i Chłodnictwo) systemy, dystrybutor czynnika chłodniczego odgrywa kluczową, choć często pomijaną rolę. Jeśli szukasz “co to jest dystrybutor czynnika chłodniczego,” “jak działa dystrybutor czynnika chłodniczego,” Lub “rodzaje dystrybutorów czynnika chłodniczego,” ten przewodnik zawiera wszystko, co musisz wiedzieć.

Whether you’re an HVACR technician, inżynier, lub właściciel domu rozwiązuje problemy z klimatyzatorem, zrozumienie dystrybutora czynnika chłodniczego może zoptymalizować wydajność systemu, zapobiegać kosztownym awariom, i zapewniają równomierne chłodzenie.

Rozłożymy to krok po kroku, od podstaw po zaawansowane rozwiązywanie problemów.

Wprowadzenie do dystrybutora czynnika chłodniczego

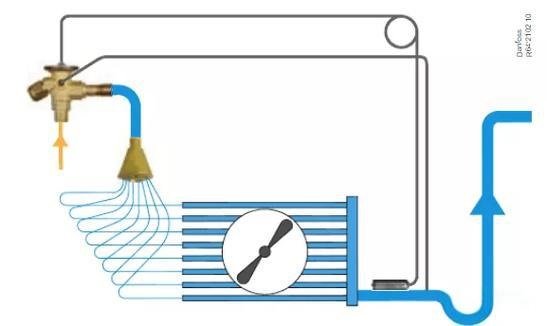

Refrigerant distributor is a vital mechanical device in chłodzenie I klimatyzacja systemy, specjalnie stosowany do równomiernego rozprowadzania cieczy i pary czynnika chłodniczego w wielu równoległych obwodach w wężownicy parownika.

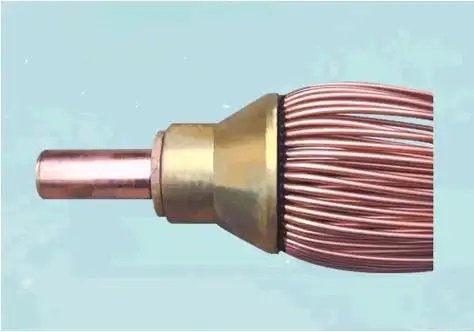

Często porównywany do A “głowica prysznicowa” na czynnik chłodniczy, zapewnia zrównoważony przepływ, zapobieganie powstawaniu gorących punktów lub nieefektywności, które mogą prowadzić do nierównomiernego chłodzenia lub obciążenia systemu.

In HVACR setups, dystrybutor znajduje się pomiędzy termostatycznym zaworem rozprężnym (TXV) i parownik, postępowania z nasyconym czynnikiem chłodniczym (mieszanina cieczy i gazu) aby zapewnić optymalną absorpcję ciepła.

Dlaczego to ma znaczenie??

Zła dystrybucja może spowodować zamrożenie cewki, zmniejszona wydajność, lub uszkodzenie sprężarki.

Dla pytających “funkcja dystrybutora czynnika chłodniczego,” jest to zasadniczo korektor, który maksymalizuje transfer energii, poprawa ogólnej wydajności systemu nawet o 20 ~ 30% w parownikach wieloobwodowych. Ten przewodnik wyjaśnia tę tajemnicę zarówno początkującym, jak i profesjonalistom.

Historia i ewolucja dystrybutorów czynników chłodniczych

The story of refrigerant distributor mirrors the broader evolution of refrigerants and HVACR tech, którego początki sięgają końca XIX wieku, kiedy pojawiło się chłodzenie mechaniczne. W 1876, Niemiecki inżynier Carl von Linde opatentował procesy skraplania gazu, kładąc podwaliny pod nowoczesne systemy. Pierwsi dystrybutorzy byli prymitywni, opierając się na prostych rozdzielaczach bez precyzyjnego mieszania.

Do lat dwudziestych XX wieku, wraz z wynalezieniem chlorofluorowęglowodorów (CFC) przez Thomasa Midgleya, dystrybutorzy ewoluowali, aby obsługiwać bardziej lotne czynniki chłodnicze, takie jak R12. Lata 70. i 80. XX wieku przyniosły postęp w obliczu problemów środowiskowych, przejście z CFC na HCFC (np., R22). Dystrybutorzy wbudowali dysze dla lepszej kontroli prędkości, rozwiązując problemy takie jak nierówny przepływ w większych cewkach.

Dzisiaj, wraz z wycofywaniem R22 na mocy Protokołu Montrealskiego i wzrostem liczby HFC, takich jak R410a, R32, R404, itp. nowoczesne dystrybutory charakteryzują się wymiennymi kryzami i konstrukcjami Venturiego zapewniającymi niski współczynnik GWP (Potencjał globalnego ocieplenia) czynniki chłodnicze. Przyszłe trendy wskazują na przyjazne dla środowiska adaptacje systemów opartych na CO2, emphasizing sustainability in HVACR evolution.

Jak działa dystrybutor czynnika chłodniczego

Zrozumienie “jak działa dystrybutor czynnika chłodniczego” rozpoczyna się od umieszczenia go w obiegu chłodniczym. Po tym, jak TXV odmierza czynnik chłodniczy do dystrybutora, urządzenie wykorzystuje dyszę przyspieszającą przepływ, tworząc spadek ciśnienia, który jednorodnie miesza fazę ciekłą i gazową.

Ta mieszanina o dużej prędkości rozgałęzia się następnie w rurki kapilarne lub obwody, zapewniając równomierne parowanie w całej wężownicy.

Kluczowe etapy działania:

- Faza wlotowa: Nasycony czynnik chłodniczy wpływa z TXV pod umiarkowanym ciśnieniem.

- Komora mieszania: Wewnętrzne przegrody lub efekty Venturiego mieszają czynnik chłodniczy, osiągnięcie 50-70% jakość pary zapewniająca równomierną dystrybucję.

- Dystrybucja outletowa: Rury zasilają parownik, gdzie czynnik chłodniczy pochłania ciepło, zamienia się w parę przed powrotem do sprężarki.

- Dynamika ciśnienia: Właściwy rozmiar utrzymuje a 5-10 spadek psi, zapobieganie stratyfikacji (gromadzenie się cieczy).

W parownikach wieloobiegowych, to zapobiega “zła dystrybucja,” gdzie niektóre sekcje przekarmiają, inne zaś głodują, prowadząc do nieefektywności. Dla wzrokowców, wyobraźcie sobie to jako policjanta drogowego kierującego czynnikiem chłodniczym “samochody” aby uniknąć zacięć.

Rodzaje dystrybutorów czynników chłodniczych

Nie wszyscy dystrybutorzy czynnika chłodniczego są sobie równi — wybór zależy od wielkości systemu, Typ czynnika chłodniczego, i projekt parownika. Oto zestawienie popularnych typów:

| Typ | Opis | Najlepsze dla | Kluczowe funkcje |

|---|---|---|---|

| Nozzle | Wykorzystuje wymienne kryzy do kontroli przepływu; przypomina perforowaną czapkę | Elastyczne zastosowania, takie jak komercyjne jednostki prądu przemiennego | Regulowany rozmiar, łatwe modernizacje; dobrze radzi sobie z R-410A |

| Venturi-Flo | Jednoczęściowe urządzenie z dyszą Venturiego do naturalnego mieszania poprzez zwiększenie prędkości | Systemy o dużej wydajności | No loose parts, reduces clogging; ideal for R-134a |

| RD (Liquid Distributor) | Danfoss-style with uniform branching for multi-section evaporators | Industrial refrigeration | Compatible with R-404A, R-407C; ensures low void fractions |

| Flange Inlet (np., Types 1109/1124) | Bolts directly to TXV outlet with male flange | Sporlan-integrated systems | Kompaktowy, vibration-resistant; for smaller residential units |

| Orifice Distributors | Basic showerhead-like design with fixed holes | Budget setups | Prosty, cost-effective; common in older R-22 systems |

Choose based on refrigerant (np., R410a needs higher pressure tolerance) and circuit count—up to 12 for large coils.

Importance in HVACR Systems

Refrigerant distributor is non-negotiable for efficiency in modern HVACR. It promotes uniform heat transfer, reducing energy use by ensuring every coil section evaporates refrigerant optimally. Without it, systems suffer:

- Uneven Cooling: Hot/cold spots in rooms.

- Compressor Overload: Floodback from imbalanced flow.

- Efficiency Losses: Aż do 15% higher energy bills.

In commercial settings, it extends equipment life by minimizing thermal stress. For eco-conscious searches like “refrigerant distributor energy savings,” note it supports low-GWP transitions, aligning with EPA regulations.

Installation Guide for Refrigerant Distributors

Proper refrigerant distributor installation is critical to avoid leaks or restrictions. Always follow manufacturer specs (np., Parker Sporlan guidelines). Tools needed: torque wrench, flux, brazing torch.

Step-by-step:

- Prep the System: Evacuate refrigerant; isolate the evaporator.

- Mount the Distributor: Position horizontally above the coil header, 6-12 inches from TXV. Secure with clamps.

- Connect Inlet: Braze or bolt to TXV outlet; use ASC (Automatic Distributor Selector) if needed for nozzle retention.

- Attach Outlet Tubes: Cut to length (match coil circuits); zakończ końcówki i połącz ze złączkami. Zapewnij równe długości dla równowagi.

- Zaizoluj i przetestuj: Owinąć pianką; próba ciśnieniowa o godz 300 psi, następnie sprawdź szczelność za pomocą azotu.

- Opłata i prowizja: Dodaj czynnik chłodniczy; monitorować przegrzanie (8-12Cel °F).

Dla napiwku: Dla R410a, użyj dłuższych rurek dla lepszego mieszania. Aby zapewnić bezpieczeństwo, zapoznaj się z lokalnymi przepisami.

Wskazówki dotyczące konserwacji zapewniające dłuższą żywotność

Regularna konserwacja dystrybutora czynnika chłodniczego zapobiega 80% niepowodzeń. Zaplanuj kontrole dwa razy w roku.

- Oględziny: Poszukaj korozji, luźne okucia, lub pozostałości oleju wskazujące na nieszczelności.

- Oczyść otwory: W przypadku zatkania przepłukać rozpuszczalnikiem; unikać materiałów ściernych.

- Sprawdź rurkę: Upewnij się, że nie ma żadnych załamań; wymienić, jeżeli średnica została zmniejszona.

- Dostosowanie całego systemu: Sprawdź działanie TXV i przegrzanie; wyregulować dystrybutor w przypadku wykrycia braku równowagi przepływu.

- Czystość czynnika chłodniczego: Używaj filtrów, aby zapobiec zanieczyszczeniom; zmieniać co roku.

Dla “czyszczenie dystrybutora czynnika chłodniczego,” w przypadku większości typów wystarczy zwykły przedmuch azotu. To wydłuża życie 10+ lata.

Typowe problemy i rozwiązywanie problemów u dystrybutora czynnika chłodniczego

Rozwiązywanie problemów z dystrybutorem czynnika chłodniczego często ujawnia ograniczenia lub awarie.

Objawy: Niskie ciśnienie ssania, zamrożenie cewki, lub nierówne temperatury.

| Wydanie | Powoduje | Rozwiązywanie problemów |

|---|---|---|

| Nierówna dystrybucja | Zatkana dysza lub nierówne długości rurek | Pomiar przepływów; zmienić rozmiar otworów; wyrównać rurki |

| Zamrożenie | Niska opłata lub ograniczenie | Sprawdź przegrzanie; rozmrozić i naładować; sprawdzić, czy nie ma zanieczyszczeń |

| Wycieki | Uszkodzenie złącza lutowanego | Lutowanie naprawić lub wymienić; używać 45% srebrny lut |

| Słabe miksowanie | Zużyta zwężka Venturiego | Wymień dystrybutora; spadek prędkości testowej |

Użyj mierników: Celuj w przegrzanie na poziomie 5–10°F. Jeśli trwałe, zadzwoń do profesjonalisty, aby uniknąć uszkodzenia sprężarki.

Wniosek

Opanowanie dystrybutora czynnika chłodniczego odblokowuje efektywność, reliable HVACR performance. Od mechaniki napędzanej zwężką Venturiego po wszechstronność typu dyszy, ten komponent zapewnia płynne działanie systemu.

Pamiętać: Zainstaluj poprawnie, zachować pilnie, i proaktywnie rozwiązywać problemy. W miarę ewolucji czynników chłodniczych w kierunku zrównoważonego rozwoju, dystrybutorzy dostosują się – bądź na bieżąco dzięki zasobom takim jak ASHRAE.

Więcej na ten temat “najlepsze praktyki dystrybutorów czynników chłodniczych,” dodaj ten przewodnik do zakładek.

Wszelkie uwagi?

Witamy zostaw wiadomość lub opublikuj ponownie.