| Tiada Pengeluaran Ais | Isu kuasa, masalah bekalan air,komponen yang tidak berfungsi. | 1. Periksa bekalan kuasa dan sambungan. |

| | 2. Memastikan bekalan air mencukupi dan tidak tersumbat. |

| | 3. Periksa injap salur masuk air untuk sebarang isu. |

| | 4. Periksa penyejat dan pemeluwap untuk kerosakan. |

| Ais tidak mencukupi | Aliran air rendah, masalah dengan tetapan suhu, masalah penyejuk. | 1. Periksa dan bersihkan penapis air. |

| | 2. Laraskan tetapan suhu jika perlu. |

| | 3. Sahkan tahap penyejuk dan cas semula jika perlu. |

| | 4. Pastikan pam air berfungsi dengan betul. |

| Isu Kualiti Ais | Air kotor, pengumpulan mineral, masalah dengan penapisan air. | 1. Bersihkan mesin ais dengan teliti. |

| | 2. Gantikan penapis air dengan kerap. |

| | 3. Periksa bekalan air untuk kekotoran. |

| | 4. Laraskan tetapan kekerasan air jika berkenaan. |

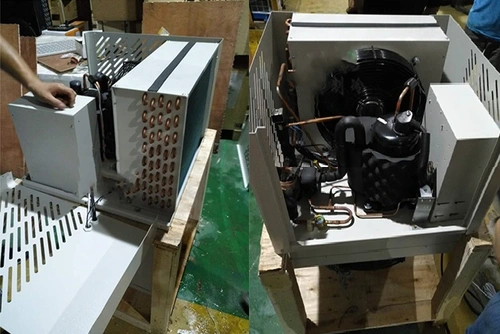

| Bunyi Berlebihan | Komponen longgar atau rosak, masalah dengan pemampat. | 1. Ketatkan komponen yang longgar. |

| | 2. Periksa sebarang objek asing yang menyebabkan bunyi bising. |

| | 3. Periksa pemampat untuk masalah. |

| | 4. Pelincir bahagian yang bergerak jika perlu. |

| Air Bocor | Longkang tersumbat, tali air rosak, masalah dengan injap masuk air. | 1. Bersihkan sebarang serpihan dari longkang. |

| | 2. Periksa saluran air untuk kebocoran dan ganti jika perlu. |

| | 3. Periksa injap salur masuk air untuk kerosakan. |

| | 4. Pastikan tekanan air yang betul. |

| Isu Paparan/Kawalan | Kerosakan elektronik, masalah sensor. | 1. Periksa kuasa pada panel kawalan. |

| | 2. Kalibrasi atau gantikan penderia yang tidak berfungsi. |

| | 3. Tetapkan semula panel kawalan jika berkenaan. |

| | 4. Kemas kini perisian tegar/perisian jika tersedia. |

| Lebihan pengeluaran ais | Kawalan tidak berfungsi, sensor yang rosak. | 1. Semak dan ukur semula sistem kawalan. |

| | 2. Periksa dan gantikan penderia yang tidak berfungsi. |

| | 3. Pastikan mesin ais ditetapkan kepada pengeluaran yang betul. |

| | 4. Periksa sebarang halangan di laluan pengeluaran ais. |

| Ais Mencair Pramatang | Suhu persekitaran yang tinggi, termostat rosak. | 1. Semak dan laraskan tetapan termostat. |

| | 2. Pastikan kawasan penyimpanan ais terlindung dengan betul. |

| | 3. Semak masalah pengudaraan di lokasi mesin. |

| | 4. Sahkan bahawa pemeluwap bersih dan berfungsi dengan baik. |

| Mesin Ais Terlalu Panas | Suhu persekitaran yang tinggi, pengudaraan yang lemah, kipas kondenser tidak berfungsi. | 1. Tingkatkan pengudaraan di lokasi mesin ais. |

| | 2. Bersihkan gegelung kondenser dengan kerap. |

| | 3. Periksa dan gantikan kipas kondenser yang rosak. |

| | 4. Kurangkan beban kerja jika mesin sentiasa berjalan. |

| Mesin Ais Tidak Dihidupkan | Isu bekalan kuasa, papan kawalan yang rosak, pendawaian yang rosak. | 1. Periksa bekalan kuasa dan sambungan. |

| | 2. Periksa dan gantikan papan kawalan yang tidak berfungsi. |

| | 3. Periksa kord kuasa dan pendawaian untuk sebarang kerosakan. |

| | 4. Uji dan ganti suis hidup/mati yang rosak jika perlu. |

| Mesin Ais Membeku | Isu penyejuk, suhu persekitaran yang rendah, termostat tidak berfungsi. | 1. Sahkan dan laraskan paras penyejuk. |

| | 2. Pastikan suhu ambien berada dalam julat yang ditetapkan. |

| | 3. Gantikan termostat yang rosak. |

| | 4. Bersihkan gegelung penyejat secara kerap. |

| Pengeluaran Ais Tidak Sekata | Pengagihan air tidak sekata, pam air rosak, masalah dengan sensor paras air. | 1. Periksa tersumbat atau sekatan dalam pengagihan air. |

| | 2. Pastikan pam air mengagihkan air secara sama rata. |

| | 3. Kalibrasi atau gantikan penderia paras air. |

| | 4. Sahkan injap salur masuk air berfungsi dengan baik. |