Pourquoi est-il nécessaire de régler les pièges à huile?

Lorsqu'il y a une grande différence de hauteur dans le système de tuyauterie de réfrigération entre l'unité d'évaporateur (unité intérieure) et unité de condensation ( unité extérieure), Doit installer des pièges à huile sur le tuyau vertical pour empêcher l'huile de réfrigérant de ne pas revenir efficacement vers le compresseur, ce qui pourrait autrement affecter les compresseurs’ durée de vie.

Le rôle de l'huile dans les systèmes de réfrigération

L'huile est essentielle dans le compresseur de réfrigération car il lubrifie les pièces mobiles, réduit la friction, et aide à sceller les composants pour maintenir la pression.

Dans la plupart des systèmes, Mélange d'huile avec un réfrigérant et se déplace à travers la tuyauterie. Ceci est nécessaire pour le compresseur’S SANTÉ, Mais cela signifie également que l'huile doit reculer correctement après avoir quitté le compresseur.

En réfrigération à basse température, par exemple, l'huile’Les changements de viscosité rendront le retour plus difficile.

En résumé, Une bonne gestion du pétrole est essentielle pour prévenir la défaillance du compresseur, en particulier dans les systèmes manipulant des rhumes extrêmes.

| Type d'huile | Viscosité (CST à 40 ° C) | Miscibilité avec les réfrigérants | Utilisation courante | Données sur les performances |

|---|---|---|---|---|

| Huile minérale | 32-68 | Bas avec HFCS | Systèmes hérités | 10% Efficacité plus faible dans les configurations modernes |

| Poe (Polyols ester) | 22-100 | Haut avec HFCS / HFOS | AC moderne | Améliore le retour par 20% à faible tempête |

| Pagir (Polyalkylène glycol) | 46-150 | Haut avec R-134A | Automobile | Réduit la migration par 15% |

Comparez les types d'huile dans les systèmes de réfrigération

Problèmes communs sans pièges à pétrole

| Problème | Description | Données sur les données |

|---|---|---|

| Pénurie d'huile | Retour faible au compresseur | 25% taux d'échec plus élevé |

| Baisse de l'efficacité | Accumulation d'huile d'évaporateur | 5-15% perte de transfert de chaleur |

| Temps d'arrêt de la limace | Vannes de dommage des touffes d'huile | 10-20% Coûts de réparation élevés |

Avantages de l'installation de pièges à huile

Installer des pièges à huile offre plusieurs avantages qui en font un incontournable dans de nombreuses configurations de réfrigération.

Ils protègent le compresseur en empêchant la famine ou la fraude à l'huile, qui étend le système’S de la durée de vie et réduit les coûts de maintenance.

L'efficacité énergétique s'améliore à mesure que l'évaporateur reste à l'écart des films d'huile qui entravent l'échange de chaleur.

Dans les applications commerciales, Cela se traduit par un fonctionnement fiable pendant les charges de pointe.

| Métrique | Avec des pièges | Sans pièges | Données de bénéfice |

|---|---|---|---|

| Efficacité | 90-95% | 75-85% | 10-20% soulèvement |

| Durée de vie | 10-15 années | 7-10 années | 20-30% extension |

| Coût énergétique | $800/année | $1,000/année | 15-20% économies |

Quand devrait installer des pièges à huile?

1. Lorsque l'unité de condensation est plus élevée que l'unité d'évaporateur

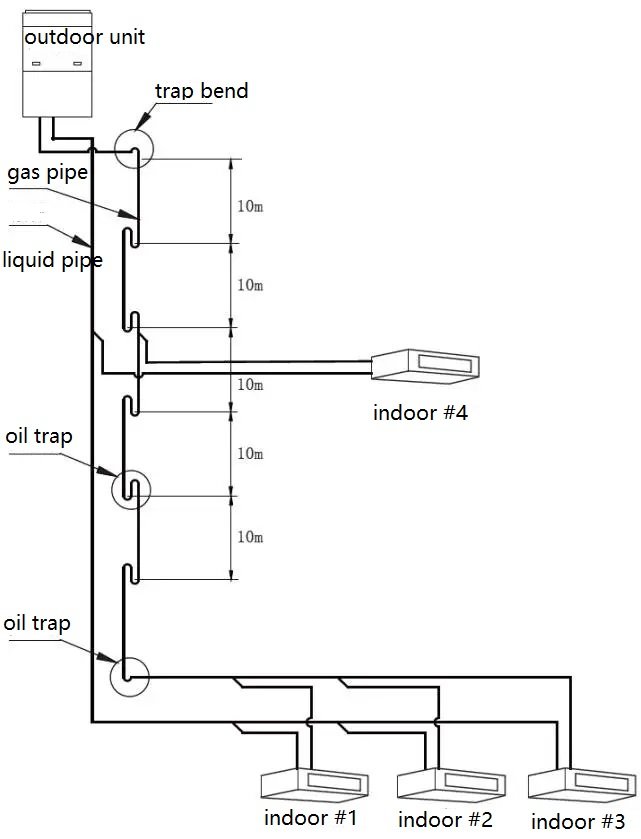

Il y a un tuyau vertical entre l'évaporateur et le tuyau d'aspiration principal. Puisque l'huile de réfrigérant ne fait pas’t s'évaporent à l'intérieur de l'évaporateur, il s'accumule en bas. Quand trop d'huile s'accumule, il bloquera le tuyau d'aspiration.

Si vous installez des pièges à huile au bas de l'évaporateur, La quantité d'huile stockée dans le piège a gagné’t à être excessif. Dès que le piège est presque plein, La différence de pression des deux côtés sera suffisante pour «pomper» l'huile hors du piège, Poussez-le vers le tuyau d'aspiration horizontal en haut, puis laissez-le couler vers le compresseur.

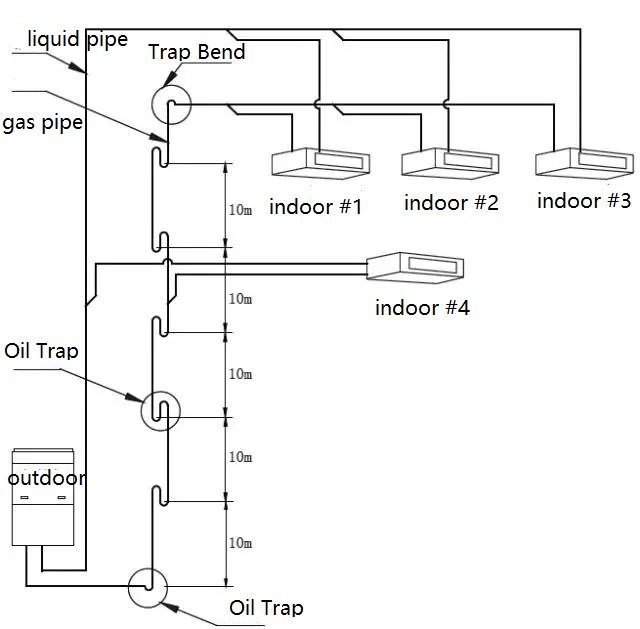

Si le tuyau en cuivre vertical est très long et que l'huile ne soit pas pompée jusqu'au sommet, devrait installer un piège à huile à intervalles le long de la colonne montante (Par exemple, Tous les 6 ~ 10 mètres) Pour s'assurer que l'huile reviendra au compresseur par étapes.

2. Lorsque l'unité de condensation est inférieure à l'unité d'évaporateur avec une grande différence de hauteur

Même sans piège à huile, L'huile coulerait automatiquement vers le compresseur par gravité. Cependant, La préoccupation ici est que trop d'huile pourrait revenir à la fois, provoquant le compresseur «lim (limace d'huile).”

Pour éviter cela, devrait installer des pièges à huile à intervalles (Par exemple, Tous les 6 ~ 10 mètres) le long du tuyau d'aspiration afin que l'huile revienne au compresseur progressivement par étapes.

3. Pendant l'opération à faible charge

L'huile peut s'accumuler dans le piège, mais en raison de la vitesse du réfrigérant limité, L'effet de retour entraîné uniquement par la différence de pression lorsque le piège est presque bloqué est très petit. La clé est d'augmenter régulièrement la sortie du compresseur pour augmenter la vitesse d'aspiration et améliorer le retour d'huile.

Si la vitesse d'aspiration peut passer à un niveau suffisamment élevé, Ensuite, il n'est pas nécessaire d'ajouter des pièges à huile supplémentaires. Cependant, en réalité, Dans des conditions à faible charge, L'effet d'échange de chaleur interne provoque une augmentation excessive de la sortie du compresseur, ce qui peut entraîner des problèmes de contrôle du système tels que la pression d'aspiration excessivement faible et le manque de surchauffe d'aspiration.

Cela signifie que l'augmentation de la vitesse d'aspiration est limitée. Donc, Quand il y a une grande différence de hauteur, il est nécessaire d'utiliser des pièges à huile pour retourner l'huile étape par étape.

Principes pour l'installation de pièges à huile

1. Lorsqu'il y a une différence de hauteur entre les unités intérieures et extérieures, Installez un piège à pétrole sur la section verticale du gaz (succion) tuyau tous les 8 à 10 mètres du bas en haut.

Le piège à huile peut être fabriqué à l'aide de deux virages en forme de «U» ou d'un virage en forme de «O», avec une hauteur 3 ~ 5 fois le diamètre du tuyau.

Quoi’c'est plus, Installez un piège à huile au point le plus bas et un pliage de piège au point le plus élevé.

2. Le tuyau de décharge doit concevoir de la même manière que le tuyau d'aspiration, doit considérer: Contrôle de la chute de pression, Assurer un bon rendement en pétrole, et empêcher la frappe liquide, bruit, et vibration.

| UN | UN | R | C |

|---|---|---|---|

| millimètre | pouce | millimètre | millimètre |

| Φ19.05 | 3/4 | ≥34 | ≤105 |

| Φ22.2 | 7/8 | ≥31 | ≤150 |

| Φ25.4 | 1/1 | ≥45 | ≤150 |

| Φ28.6 | 9/8 | ≥45 | ≤150 |

| Φ34.9 | 11/8 | ≥60 | ≤250 |

| Φ38.1 | 12/8 | ≥60 | ≤350 |

| Φ41.3 | 13/8 | ≥80 | ≤450 |

| Φ44.45 | 7/4 | ≥80 | ≤500 |

| Φ54.1 | 17/8 | ≥90 | ≤500 |

Dimensions pour les pièges à huile et les pliages de pièges

(Remarques: « UN » signifie diamètre extérieur en cuivre, « R » signifie min. Rayon de pliage des pièges à huile, « C » signifie max. Longueur de tuyau droit entre les pièges à huile)

Exigences techniques pour installer des pièges à huile

Unité extérieure sous l'unité intérieure

Unité extérieure au-dessus de l'unité intérieure

Conclusion

Les pièges à huile sont essentiels dans les systèmes de réfrigération pour assurer un bon retour d'huile au compresseur, surtout quand il y a des différences de hauteur verticale ou des conditions de faible charge.

Les pièges à huile correctement installés empêchent l'accumulation d'huile, réduire le risque de dommages au compresseur, et aider à maintenir un fonctionnement du système efficace et fiable.

Tout commentaire?

Bienvenue laisser un message ou reposter.