| Pas de production de glace | Problèmes d'alimentation, problèmes d'approvisionnement en eau,composants défectueux. | 1. Vérifier l'alimentation et les connexions. |

| | 2. Assurez-vous que l’approvisionnement en eau est adéquat et n’est pas bloqué. |

| | 3. Inspectez la vanne d’entrée d’eau pour tout problème. |

| | 4. Examiner l'évaporateur et le condenseur pour déceler tout dommage. |

| Glace insuffisante | Faible débit d'eau, problèmes avec les réglages de température, problèmes de réfrigérant. | 1. Vérifiez et nettoyez le filtre à eau. |

| | 2. Ajustez les réglages de température si nécessaire. |

| | 3. Vérifiez les niveaux de réfrigérant et rechargez si nécessaire. |

| | 4. Assurez-vous que la pompe à eau fonctionne correctement. |

| Problèmes de qualité de la glace | Eau sale, accumulation de minéraux, problèmes de filtration de l'eau. | 1. Nettoyer soigneusement la machine à glace. |

| | 2. Remplacez régulièrement les filtres à eau. |

| | 3. Inspecter l’approvisionnement en eau pour les impuretés. |

| | 4. Ajustez les paramètres de dureté de l’eau, le cas échéant. |

| Bruit excessif | Composants desserrés ou endommagés, problèmes avec le compresseur. | 1. Resserrer les composants lâches. |

| | 2. Vérifiez tout corps étranger provoquant du bruit. |

| | 3. Inspectez le compresseur pour détecter les problèmes. |

| | 4. Lubrifier les pièces mobiles si nécessaire. |

| Une fuite d'eau | Une canalisation bouchée, conduites d'eau endommagées, problème avec la vanne d'arrivée d'eau. | 1. Éliminez tous les débris du drain. |

| | 2. Vérifiez les conduites d'eau pour déceler les fuites et remplacez-les si nécessaire. |

| | 3. Inspectez la vanne d’arrivée d’eau pour déceler tout dommage. |

| | 4. Assurer une bonne pression d’eau. |

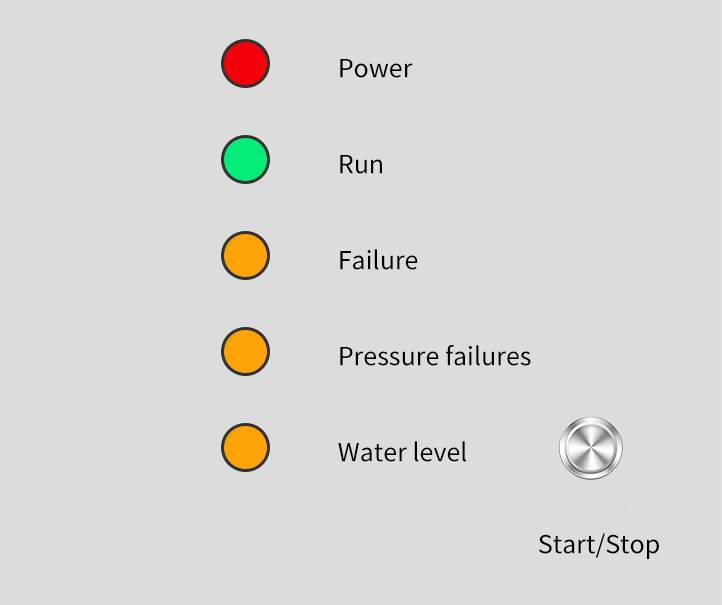

| Problèmes d'affichage/de contrôle | Dysfonctionnements électroniques, problèmes de capteur. | 1. Vérifier l'alimentation du panneau de commande. |

| | 2. Calibrer ou remplacer les capteurs défectueux. |

| | 3. Réinitialisez le panneau de commande le cas échéant. |

| | 4. Mettre à jour le firmware/logiciel si disponible. |

| Ice Over-production | Contrôle défectueux, capteurs défectueux. | 1. Vérifier et recalibrer le système de contrôle. |

| | 2. Inspecter et remplacer les capteurs défectueux. |

| | 3. Assurez-vous que la machine à glace est réglée sur la bonne production. |

| | 4. Vérifiez toute obstruction dans le chemin de production de glace. |

| Fonte prématurée des glaces | Température ambiante élevée, thermostat défectueux. | 1. Vérifiez et ajustez les paramètres du thermostat. |

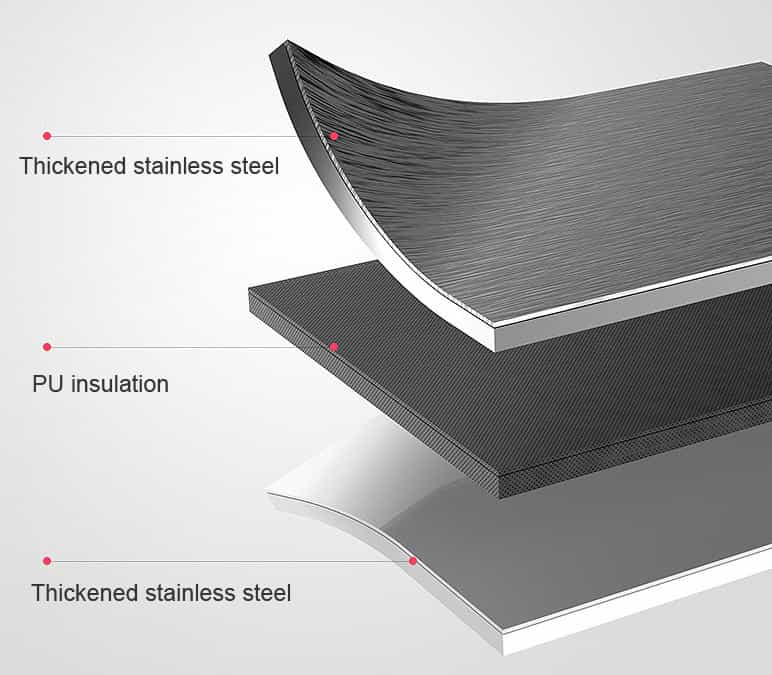

| | 2. Assurez-vous que la zone de stockage de glace est correctement isolée. |

| | 3. Vérifiez les problèmes de ventilation à l’emplacement de la machine. |

| | 4. Vérifiez que le condenseur est propre et fonctionne bien. |

| Surchauffe de la machine à glace | Température ambiante élevée, mauvaise ventilation, ventilateur du condenseur défectueux. | 1. Améliorer la ventilation à l’emplacement de la machine à glace. |

| | 2. Nettoyer régulièrement les serpentins du condenseur. |

| | 3. Vérifier et remplacer un ventilateur de condenseur défectueux. |

| | 4. Réduisez la charge de travail si la machine fonctionne constamment. |

| La machine à glace ne s'allume pas | Problèmes d'alimentation, tableau de commande défectueux, câblage endommagé. | 1. Vérifier l'alimentation et les connexions. |

| | 2. Inspecter et remplacer un tableau de commande défectueux. |

| | 3. Examinez le cordon d'alimentation et le câblage pour déceler tout dommage. |

| | 4. Testez et remplacez un interrupteur marche/arrêt défectueux si nécessaire. |

| La machine à glace gèle | Problèmes de réfrigérant, basse température ambiante, thermostat défectueux. | 1. Vérifier et ajuster les niveaux de réfrigérant. |

| | 2. Assurez-vous que la température ambiante se situe dans la plage spécifiée. |

| | 3. Remplacer un thermostat défectueux. |

| | 4. Nettoyer régulièrement les serpentins de l'évaporateur. |

| Production de glace inégale | Répartition inégale de l'eau, pompe à eau défectueuse, problèmes avec le capteur de niveau d'eau. | 1. Vérifiez les obstructions ou les restrictions dans la distribution d'eau. |

| | 2. Assurez-vous que la pompe à eau distribue l’eau uniformément. |

| | 3. Calibrer ou remplacer le capteur de niveau d'eau. |

| | 4. Vérifiez que la vanne d'arrivée d'eau fonctionne correctement. |