À China Speedway, Nous fournissons des solutions de produits de réfrigération personnalisées à nos clients. Récemment,Nous avons un client achetant une unité de chambre froide, travaillé pour un projet de chambre froide avec une distance super plus longue entre la chambre froide et l'unité de condensation extérieure. Dans cet article, Nous vous donnerons un exemple réel comment avons-nous travaillé dans ce projet de chambre froide et garder les produits stockés frais et durables, Donc, comme référence pour les clients qui ont besoin de projets de chambre froide similaires.

Spécifications des clients

Les clients doivent contrôler avec précision la portée de la température de la chambre froide pour éviter tout dommage pour les marchandises, Voici les détails de ce projet de chambre froide.

Pays: Émirats arabes unis

Température ambiante: Max 50 ~ 55 ° C ( Maximum 15 jours pour le total en été)

Taille de la chambre froide: 7X3,5x2,5m (longueur x largeur x hauteur)

Application de la chambre froide: Médecine des magasins

Température de la chambre froide: Constant 2 ~ 8 ° C

Emplacement de l'unité de condensation de l'onduleur: Sur le toit (Totalement six étages)

Emplacement de la chambre froide: Sous-sol

Distance directe entre le toit et le sous-sol: 25m

Solution de base

Unité de condensation de l'onduleur (unité extérieure): 5HP(Puissance), 220V, 1Phase 50Hz, Réfrigérant R404. avec système de protection contre les pièges à huile, avec une connexion de câble de 50 m pour afficher la carte de l'écran. Comme la température ambiante maximale est de 50 à 55 ° C, il faut donc utiliser une unité de condensation de plus grande taille (Utilisez 5hp mais pas 4hp), Besoin également d'un sheder pour abaisser la température autour de l'unité.

Unité d'évaporateur (unité intérieure): 6.5HP 220V, 1 Phase 50Hz

Panneau de chambre froide: 150Panneau de sandwich PU épaisseur de mm avec acier galvanisé de 0,35 mm

Porte chambre froide: 150Panneau de sandwich PU épaisseur de mm avec seuil de hauteur de 10 cm ( pour une meilleure étanche à l'air), taille de la chambre froide–1.8×0.9m (hauteur x largeur)

Porte de chambre froide avec seuil

Solution spécifique

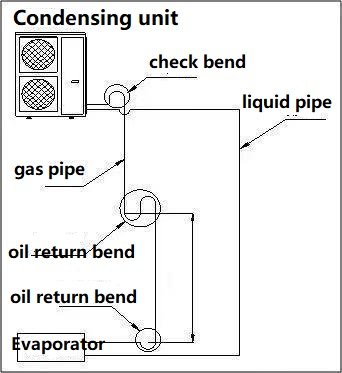

1. Utiliser un piège à huile (virage de retour) système ( faire plusieurs pièges à huile lors de l'installation du tuyau) , max préparant le câble de 50 m pour éviter toute longueur, Voir le projet à ci-dessous:

Dessin d'installation de tuyaux

2. Préparer 2 Définit les équipements de réfrigération ( Chaque ensemble comprenait une unité de condensation 1PC et une unité d'évaporatrice 1PC), Pour éviter tout dommage soudain.

3. Préparer un plastique rideau à bande d'air Pour éviter tout air de refroidissement à gaspiller.

4. Minimiser la longueur d'installation, Parce que plus plus longtemps signifie plus de chances de perdre l'air de refroidissement.

5. Utilisez le scellant pour obtenir une meilleure étanche à l'air, Parce que la température ambiante nécessite une constante 2 ~ 8 ° C

6. Préparez un générateur diesel de 20 ~ 25kva (qui peut fournir à la fois 220 V et 380 V) pour la sauvegarde quand une panne soudaine.

7. Utilisez un équilibre de fenêtre avec 220 V 50 Hz pour équilibrer la pièce à l'intérieur et à l'extérieur.

8. Utilisez un ou deux légers de la pièce froide à LED pour garder la lumière clairement à l'intérieur de la pièce froide.

9. Utilisez la carte d'écran d'affichage LED pour l'unité de condensation de l'onduleur pour surveiller la température ambiante froide en temps réel.

Carte d'écran d'affichage LED

Besoin d'une solution de chambre froide personnalisée?

À « Chine Speedway », Nous sommes des experts pour fournir une solution de chambre froide personnalisée pour différentes applications. La température ambiante peut être + 15 ~ -40 ° C, Si vous avez besoin d'une autre température spéciale, peut nous montrer toutes les exigences en conséquence.

Nous vous soutiendrons comment effectuer une installation spécifiquement et fournir des dessins pour un ensemble de panneaux de pièce froide, Pendant ce temps, donnez tous les conseils sur la chambre froide à travailler correctement et durer une vie plus longue.

N'hésitez pas à nous contacter pour plus de détails ou à discuter de vos besoins spécifiques. Nous sommes impatients de vous aider à optimiser vos systèmes de haute qualité, Solutions de chambre froide conçue avec précision.