Dans le monde du CVC (Chauffage, Ventilation, Climatisation, et réfrigération) systèmes, Le distributeur de réfrigérant joue un rôle crucial mais souvent négligé. Si tu’je cherche « qu'est-ce qu'un distributeur de réfrigérant, » « comment fonctionne un distributeur de réfrigérant, » ou « types de distributeurs de réfrigérant, » ce guide couvre tout ce que vous devez savoir.

Que vous’vous êtes un technicien CVC, ingénieur, ou le propriétaire dépanne votre unité de climatisation, comprendre le distributeur de réfrigérant peut optimiser l’efficacité du système, éviter des pannes coûteuses, et assure un refroidissement uniforme.

Nous’je vais le décomposer étape par étape, des bases au dépannage avancé.

Introduction au distributeur de réfrigérant

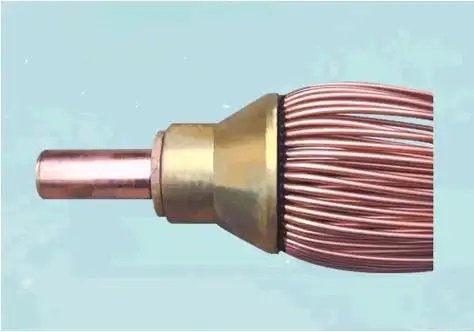

Le distributeur de réfrigérant est un dispositif mécanique essentiel dans réfrigération et climatisation systèmes, spécifiquement utilisé pour disperser uniformément le réfrigérant liquide et vapeur sur plusieurs circuits parallèles dans un serpentin d'évaporateur.

Souvent comparé à un « pomme de douche » pour réfrigérant, il assure un flux équilibré, prévenir les points chauds ou les inefficacités qui pourraient entraîner un refroidissement irrégulier ou une tension sur le système.

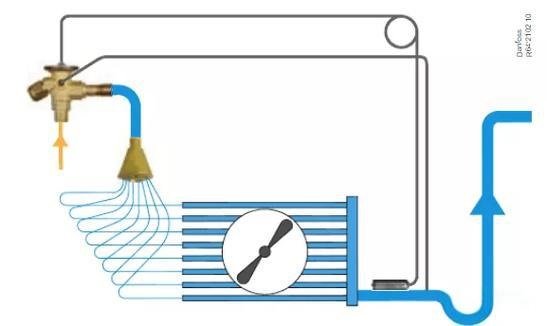

Dans les configurations CVCR, le distributeur se situe entre le détendeur thermostatique (TXV) et l'évaporateur, manipulation de réfrigérant saturé (un mélange de liquide et de gaz) pour favoriser une absorption optimale de la chaleur.

Pourquoi est-ce important?

Une mauvaise distribution peut provoquer le gel de la batterie, efficacité réduite, ou dommage au compresseur.

Pour ceux qui interrogent « fonction du distributeur de réfrigérant, » il’c'est essentiellement l'égaliseur qui maximise le transfert d'énergie, améliorant les performances globales du système jusqu'à 20 à 30 % dans les évaporateurs multi-circuits. Ce guide le démystifie aussi bien pour les débutants que pour les pros.

Histoire et évolution des distributeurs de réfrigérant

L'histoire du distributeur de réfrigérant reflète l'évolution plus large des réfrigérants et de la technologie HVACR, datant de la fin du 19ème siècle, lorsque la réfrigération mécanique est apparue. Dans 1876, L'ingénieur allemand Carl von Linde a breveté des procédés de liquéfaction des gaz, jeter les bases de systèmes modernes. Les premiers distributeurs étaient rudimentaires, s'appuyant sur des collecteurs simples sans mélange précis.

Dans les années 1920, avec l'invention des chlorofluorocarbures (CFC) par Thomas Midgley, les distributeurs ont évolué pour gérer des réfrigérants plus volatils comme le R12. Les années 1970 et 1980 ont vu des progrès sur fond de préoccupations environnementales, passer des CFC aux HCFC (par exemple., R22). Distributeurs intégrant des buses pour un meilleur contrôle de la vitesse, résoudre des problèmes tels que le débit inégal dans les bobines plus grandes.

Aujourd'hui, avec l'élimination progressive du R22 dans le cadre du Protocole de Montréal et la montée en puissance des HFC comme le R410a, R32, R404, etc.. les distributeurs modernes comportent des orifices interchangeables et des conceptions venturi pour un faible GWP (Potentiel de réchauffement climatique) réfrigérants. Les tendances futures pointent vers des adaptations écologiques pour les systèmes basés sur le CO2, mettre l'accent sur la durabilité dans l'évolution du CVC.

Comment fonctionne un distributeur de réfrigérant

Compréhension « comment fonctionne un distributeur de réfrigérant » commence par son placement dans le cycle de réfrigération. Après que le TXV dose le fluide frigorigène dans le distributeur, l'appareil utilise une buse pour accélérer le débit, créant une chute de pression qui mélange les phases liquide et vapeur de manière homogène.

Ce mélange à grande vitesse se divise ensuite en tubes ou circuits capillaires, assurant une évaporation uniforme à travers le serpentin.

Étapes clés du fonctionnement:

- Phase d'entrée: Le réfrigérant saturé entre du TXV à une pression modérée.

- Chambre de mélange: Des chicanes internes ou des effets venturi agitent le réfrigérant, atteindre 50-70% qualité de la vapeur pour une distribution uniforme.

- Distribution de points de vente: Des tubes alimentent l'évaporateur, où le réfrigérant absorbe la chaleur, se transformer en vapeur avant de retourner au compresseur.

- Dynamique de la pression: Un dimensionnement approprié maintient un 5-10 chute de psi, empêcher la stratification (accumulation de liquide).

Dans les évaporateurs multicircuits, cela empêche « mauvaise distribution, » où certaines sections se nourrissent tandis que d'autres meurent de faim, conduisant à des inefficacités. Pour les apprenants visuels, imaginez-le comme un agent de la circulation dirigeant le réfrigérant « voitures » pour éviter les confitures.

Types de distributeurs de réfrigérant

Tous les distributeurs de réfrigérant ne sont pas égaux : la sélection dépend de la taille du système, type de réfrigérant, et conception de l'évaporateur. Ici’s une ventilation des types courants:

| Taper | Description | Idéal pour | Principales fonctionnalités |

|---|---|---|---|

| Ajutage | Utilise des orifices interchangeables pour contrôler le débit; ressemble à un capuchon perforé | Applications flexibles comme les unités de climatisation commerciales | Taille ajustable, rénovations faciles; gère bien le R-410A |

| Venturi-Flo | Unité monobloc avec buse venturi pour un mélange naturel via augmentation de la vitesse | Systèmes haute capacité | Pas de pièces détachées, réduit le colmatage; idéal pour le R-134a |

| DR (Distributeur de liquide) | Style Danfoss avec branchement uniforme pour évaporateurs multi-sections | Réfrigération industrielle | Compatible avec le R-404A, R-407C; garantit de faibles fractions de vides |

| Entrée à bride (par exemple., Espèces 1109/1124) | Se boulonne directement à la sortie TXV avec bride mâle | Systèmes intégrés Sporlan | Compact, résistant aux vibrations; pour les petites unités résidentielles |

| Distributeurs d'orifices | Conception de base semblable à une pomme de douche avec trous fixes | Configurations budgétaires | Simple, rentable; courant dans les anciens systèmes R-22 |

Choisissez en fonction du réfrigérant (par exemple., Le R410a nécessite une tolérance de pression plus élevée) et nombre de circuits - jusqu'à 12 pour les grandes bobines.

Importance dans les systèmes CVCR

Le distributeur de réfrigérant n'est pas négociable pour l'efficacité des CVC modernes. Il favorise un transfert de chaleur uniforme, réduisant la consommation d'énergie en garantissant que chaque section du serpentin évapore le réfrigérant de manière optimale. Sans ça, les systèmes souffrent:

- Refroidissement inégal: Points chauds/froids dans les chambres.

- Surcharge du compresseur: Retour de flux dû à un débit déséquilibré.

- Pertes d'efficacité: Jusqu'à 15% factures d'énergie plus élevées.

Dans les milieux commerciaux, il prolonge la durée de vie de l'équipement en minimisant le stress thermique. Pour les recherches éco-responsables comme « économies d'énergie du distributeur de réfrigérant, » notez qu'il prend en charge les transitions à faible GWP, s'aligner sur les réglementations de l'EPA.

Guide d'installation pour les distributeurs de réfrigérant

Une installation correcte du distributeur de réfrigérant est essentielle pour éviter les fuites ou les restrictions.. Suivez toujours les spécifications du fabricant (par exemple., Lignes directrices de Parker Sporlan). Outils nécessaires: clé dynamométrique, flux, chalumeau de brasage.

Pas à pas:

- Préparez le système: Évacuer le réfrigérant; isoler l'évaporateur.

- Monter le distributeur: Positionner horizontalement au-dessus du collecteur de la bobine, 6-12 pouces de TXV. Fixer avec des pinces.

- Connecter l'entrée: Braser ou boulonner à la sortie TXV; utiliser ASC (Sélecteur de distributeur automatique) si nécessaire pour la rétention de la buse.

- Fixer les tubes de sortie: Couper à longueur (faire correspondre les circuits de bobines); se termine et se connecte avec les syndicats. Assurer des longueurs égales pour l’équilibre.

- Isoler et tester: Envelopper de mousse; essai de pression à 300 psi, puis vérifier les fuites avec de l'azote.

- Frais et commissions: Ajouter du réfrigérant; surveiller la surchauffe (8-12Cible °F).

Pour un pourboire: Pour R410a, utilisez des tubes plus longs pour un meilleur mélange. Consultez les codes locaux pour plus de sécurité.

Conseils d'entretien pour une durée de vie plus longue

L'entretien régulier du distributeur de réfrigérant évite 80% des échecs. Planifier des contrôles semestriels.

- Inspection visuelle: Recherchez la corrosion, raccords lâches, ou des résidus d'huile indiquant des fuites.

- Orifices propres: Rincer avec du solvant si bouché; éviter les abrasifs.

- Vérifier les tubes: Assurez-vous qu’il n’y a pas de plis; remplacer si diamètre réduit.

- Mise au point à l'échelle du système: Vérifier la fonction TXV et la surchauffe; ajuster le distributeur si des déséquilibres de débit sont détectés.

- Pureté du réfrigérant: Utilisez des filtres pour éviter les débris; changer chaque année.

Pour « nettoyage du distributeur de réfrigérant, » un simple soufflage d'azote suffit pour la plupart des types. Cela prolonge la vie à 10+ années.

Problèmes courants et dépannage pour le distributeur de réfrigérant

Le dépannage des problèmes du distributeur de réfrigérant révèle souvent des restrictions ou des dysfonctionnements.

Symptômes: Faible pression d'aspiration, gel du serpentin, ou des températures inégales.

| Problème | Causes | Dépannage |

|---|---|---|

| Répartition inégale | Buse bouchée ou longueurs de tube inégales | Mesurer les flux; redimensionner les orifices; égaliser les tubes |

| Gel | Faibles frais ou restrictions | Vérifier la surchauffe; décongeler et recharger; inspecter les débris |

| Fuites | Rupture du joint brasé | Braser réparer ou remplacer; utiliser 45% soudure à l'argent |

| Mauvais mélange | Venturi usé | Remplacer le distributeur; test de chute de vitesse |

Utiliser des jauges: Visez une surchauffe de 5 à 10 °F. Si persistant, appelez un professionnel pour éviter d'endommager le compresseur.

Conclusion

La maîtrise du distributeur de fluide frigorigène débloque l'efficacité, performances CVCR fiables. De sa mécanique à venturi à la polyvalence des types de buses, ce composant garantit le bon fonctionnement de votre système.

Se souvenir: Installer correctement, maintenir avec diligence, et dépanner de manière proactive. Alors que les réfrigérants évoluent vers la durabilité, les distributeurs s'adapteront : restez informés via des ressources comme ASHRAE.

Pour en savoir plus « Meilleures pratiques en matière de distributeur de réfrigérant, » ajouter ce guide à vos favoris.

Tout commentaire?

Bienvenue laisser un message ou reposter.