Por que é necessário instalar armadilhas de óleo?

Quando há uma grande diferença de altura no sistema de tubulação de refrigeração entre a unidade evaporadora (unidade interna) e unidade condensadora ( Unidade ao ar livre), deve instalar coletores de óleo no tubo vertical para evitar que o óleo refrigerante não retorne efetivamente ao compressor, que poderia afetar os compressores’ vida útil.

O papel do petróleo nos sistemas de refrigeração

O óleo é essencial no compressor de refrigeração porque lubrifica as peças móveis, reduz o atrito, e ajuda a vedar os componentes para manter a pressão.

Na maioria dos sistemas, o óleo se mistura com o refrigerante e viaja pela tubulação. Isto é necessário para a saúde do compressor, mas também significa que o óleo deve retornar corretamente após sair do compressor.

Em refrigeração de baixa temperatura, por exemplo, as mudanças na viscosidade do óleo tornarão o retorno mais desafiador.

Resumindo, o gerenciamento adequado do óleo é fundamental para evitar falhas no compressor, especialmente em sistemas que lidam com resfriados extremos.

| Tipo de óleo | Viscosidade (cSt a 40°C) | Miscibilidade com refrigerantes | Uso Comum | Dados sobre desempenho |

|---|---|---|---|---|

| Óleo mineral | 32-68 | Baixo com HFCs | Sistemas legados | 10% menor eficiência em configurações modernas |

| Poe (Éster de poliol) | 22-100 | Alto com HFCs/HFOs | AC moderno | Melhora o retorno em 20% em baixa temperatura |

| Pag (Polialquileno glicol) | 46-150 | Alto com R-134a | Automotivo | Reduz a migração em 15% |

Compare os tipos de óleo em sistemas de refrigeração

Problemas comuns sem armadilhas de óleo

| Emitir | Descrição | Dados de impacto |

|---|---|---|

| Escassez de petróleo | Baixo retorno ao compressor | 25% maior taxa de falha |

| Queda de eficiência | Acúmulo de óleo no evaporador | 5-15% perda de transferência de calor |

| Tempo de inatividade do Slug | Aglomerados de óleo danificam válvulas | 10-20% custos de reparo elevados |

Benefícios da instalação de coletores de óleo

A instalação de coletores de óleo oferece vários benefícios que os tornam essenciais em muitas configurações de refrigeração.

Eles protegem o compressor evitando a falta de óleo ou a formação de jatos, o que prolonga a vida útil do sistema e reduz os custos de manutenção.

A eficiência energética melhora à medida que o evaporador fica livre de películas de óleo que dificultam a troca de calor.

Em aplicações comerciais, isso se traduz em operação confiável durante picos de carga.

| Métrica | Com armadilhas | Sem armadilhas | Dados de benefícios |

|---|---|---|---|

| Eficiência | 90-95% | 75-85% | 10-20% elevar |

| Vida útil | 10-15 anos | 7-10 anos | 20-30% extensão |

| Custo de energia | $800/ano | $1,000/ano | 15-20% poupança |

Quando devo instalar coletores de óleo?

1. Quando a unidade condensadora é mais alta que a unidade evaporadora

Existe um tubo vertical entre o evaporador e o tubo de sucção principal. Como o óleo refrigerante não evapora dentro do evaporador, ele se acumula no fundo. Quando muito óleo se acumula, isso bloqueará o tubo de sucção.

Se instalar coletores de óleo na parte inferior do evaporador, a quantidade de óleo armazenada na armadilha não será excessiva. Assim que a armadilha estiver quase cheia, a diferença de pressão em ambos os lados será suficiente para “bombear” o óleo para fora do purgador, empurre-o até o tubo de sucção horizontal na parte superior, e então deixe-o fluir de volta para o compressor.

Se o tubo de cobre vertical for muito longo e houver preocupação de que o óleo não possa ser bombeado até o topo, deve instalar coletor de óleo em intervalos ao longo do riser (por exemplo, a cada 6~10 metros) para garantir que o óleo retornará ao compressor em etapas.

2. Quando a unidade condensadora é mais baixa que a unidade evaporadora com uma grande diferença de altura

Mesmo sem armadilha de óleo, o óleo fluiria automaticamente de volta ao compressor por gravidade. No entanto, a preocupação aqui é que muito petróleo possa retornar de uma só vez, causando “lesma líquida” no compressor (lesma de óleo).”

Para evitar isso, deve instalar coletores de óleo em intervalos (por exemplo, a cada 6~10 metros) ao longo do tubo de sucção para que o óleo retorne ao compressor gradualmente em etapas.

3. Durante operação com carga baixa

O óleo pode se acumular na armadilha, mas devido à velocidade limitada do refrigerante, o efeito de retorno impulsionado apenas pela diferença de pressão quando o purgador está quase bloqueado é muito pequeno. A chave é aumentar regularmente a produção do compressor para aumentar a velocidade de sucção e melhorar o retorno do óleo.

Se a velocidade de sucção puder aumentar para um nível suficientemente alto, então não há necessidade de adicionar coletores de óleo adicionais. No entanto, na realidade, sob condições de baixa carga, o efeito de troca de calor interno faz com que a saída do compressor aumente excessivamente, o que pode levar a problemas de controle do sistema, como pressão de sucção excessivamente baixa e falta de superaquecimento de sucção.

Isso significa que o aumento na velocidade de sucção é limitado. Portanto, quando há uma grande diferença de altura, é necessário usar coletores de óleo para devolver o óleo passo a passo.

Princípios para instalação de coletores de óleo

1. Quando há uma diferença de altura entre as unidades internas e externas, instale um coletor de óleo na seção vertical do gás (sucção) tubo a cada 8~10 metros de baixo para cima.

O coletor de óleo pode ser feito usando duas curvas em forma de “U” ou uma curva em forma de “O”, com uma altura de 3 a 5 vezes o diâmetro do tubo.

O que mais, instale um coletor de óleo no ponto mais baixo e uma curva do coletor no ponto mais alto.

2. O tubo de descarga deve ser projetado da mesma forma que o tubo de sucção, deve considerar: controlar a queda de pressão, garantir o retorno adequado do óleo, e evitar slugging líquido, barulho, e vibração.

| A | A | R | C |

|---|---|---|---|

| milímetros | polegada | milímetros | milímetros |

| Φ19,05 | 3/4 | ≥34 | ≤105 |

| Φ22,2 | 7/8 | ≥31 | ≤150 |

| Φ25,4 | 1/1 | ≥45 | ≤150 |

| Φ28,6 | 9/8 | ≥45 | ≤150 |

| Φ34,9 | 11/8 | ≥60 | ≤250 |

| Φ38,1 | 12/8 | ≥60 | ≤350 |

| Φ41,3 | 13/8 | ≥80 | ≤450 |

| Φ44,45 | 7/4 | ≥80 | ≤500 |

| Φ54,1 | 17/8 | ≥90 | ≤500 |

Dimensões para armadilhas de óleo e curvas de armadilhas

(Observações: “A” significa diâmetro externo de cobre, “R” significa mínimo. Raio de curvatura das armadilhas de óleo, “C” significa máximo. Comprimento reto do tubo entre coletores de óleo)

Requisitos técnicos para instalação de coletores de óleo

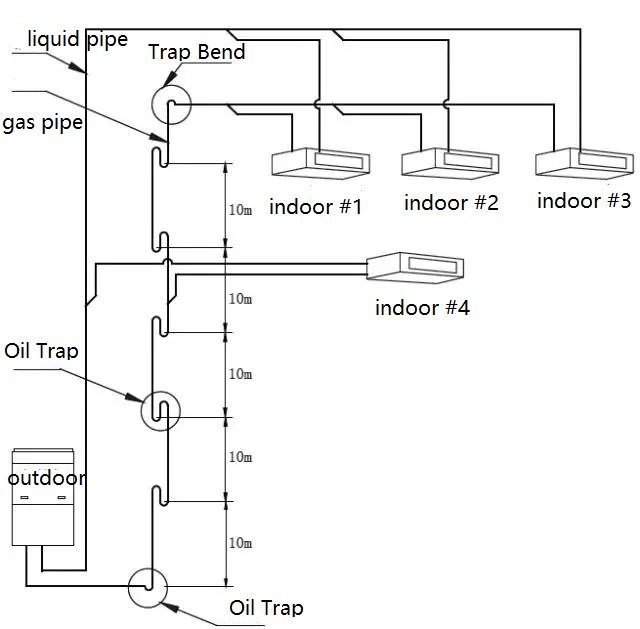

Unidade externa abaixo da unidade interna

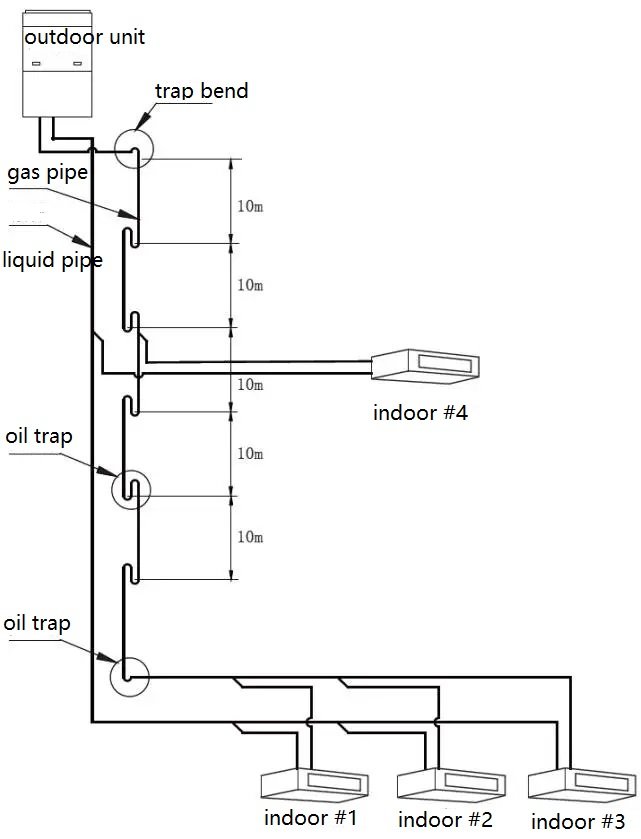

Unidade externa acima da unidade interna

Conclusão

Os coletores de óleo são essenciais em sistemas de refrigeração para garantir o retorno adequado do óleo ao compressor, especialmente quando há diferenças verticais de altura ou condições de baixa carga.

Armadilhas de óleo instaladas corretamente evitam o acúmulo de óleo, reduzir o risco de danos ao compressor, e ajudar a manter a operação eficiente e confiável do sistema.

Algum comentário?

Bem-vindo deixe uma mensagem ou repost.