OEM de parada única & Parceiro de soluções para câmaras frias ODM

Produzimos a maioria dos tipos de portas para câmaras frigoríficas com tamanhos personalizados, grossura, e materiais. Espessura da porta: 75/100/120/150/200mm ou mais. A qualidade é garantida, entre em contato conosco livremente.

Porta da câmara fria (Também chamada de porta de armazenamento refrigerado) refere-se a uma porta que é especialmente instalada em um ambiente gelado, como um freezer ou um refrigerador, para isolamento térmico e hermeticidade.

Quarto frio O projeto de isolamento visa principalmente bloquear a transferência de calor entre a câmara fria e o exterior. A porta da câmara fria de alta qualidade aumentará muito o efeito de isolamento térmico da câmara fria. E geralmente coordenado com cortinas de ar, a porta da sala fria pode efetivamente reduzir a perda de resfriamento da sala fria.

Porta deslizante automática

Porta Nunca Inflamável (Núcleo PU)

Há 2 métodos para produzir núcleo de porta de câmara fria:

#1. Poliuretano (PU) Injeção

Use máquina de moldagem por injeção de pressão PU para produzir. A estrutura de poliuretano é densa, sem encolher, e a porta é lisa e bonita.

#2. Placa de isolamento térmico

A placa de isolamento térmico PU não só tem alta resistência, mas também tem um bom efeito de isolamento térmico; Há um dispositivo de segurança na porta da câmara fria para escapar facilmente quando pessoas forem acidentalmente fechadas na câmara fria.

A superfície de ambos os lados usa aço inoxidável, cor de aço, Liga de alumínio,etc.

Os trilhos guia são feitos de liga de alumínio à prova de ferrugem, e tem um sistema anti-gelo. Todos os parafusos são galvanizados, com aço inoxidável de 2,0 mm de espessura (ou personalize seu material) moldura de porta soldada sem costura de borda, durável e não deformação.

Trilho Guia

Moldura da porta

Parafuso

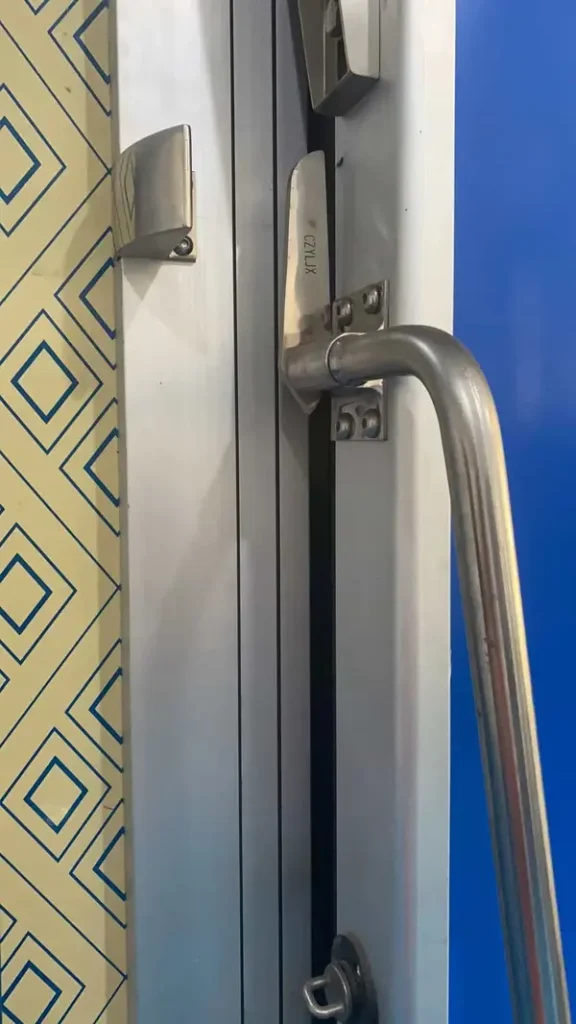

Imprensa de porta

Abridor de porta

Dispositivo de fuga de porta

Porta de câmara fria usada principalmente para logística de cadeia de frio, processamento de comida, Shopping, supermercados, hotelaria e restauração aeronáutica, biofarmacêuticos, química fina, eletrônica de precisão e outras indústrias. Enquanto isso, usado para a produção, armazenamento e logística de alimentos, medicamentos e outros produtos que requerem um ambiente de temperatura constante.

frutos do mar

Cadeia fria

Supermercado

Catering para aviação

biomedicina

Química Fina

Processamento de comida

Eletrônica de Precisão

Devido à diferença de temperatura entre o interior e o exterior da câmara fria, quando abrir a porta, o ar quente passa pela abertura para gerar forte convecção, resultando em perda de resfriamento.

A quantidade de ar quente que entra na câmara fria está relacionada com a altura e largura da porta, a diferença de temperatura entre dentro e fora da sala, e, claro, o tempo e a frequência de abertura da porta.

Você deve selecionar uma porta da câmara fria que abra e feche rapidamente, enquanto isso é melhor colocar uma cortina de ar.

#1. Selecione de acordo com a temperatura

Se você escolher uma porta de espessura mais fina para câmaras frigoríficas de baixa temperatura, não alcançará o efeito de isolamento ideal, mas vai congelar a porta, e danificar a porta.

A temperatura do resfriador é de -15℃~+10℃, você pode escolher 100mm (10cm) porta de espessura; Congelador é -30 ~ -15℃, escolha 150 mm (15cm) porta de espessura; O freezer rápido é de -30 ℃ ~ -45 ℃, você deve escolher 200mm (20cm) porta de espessura.

De acordo com a diferença de temperatura, a espessura da porta da câmara fria pode ser selecionada 50, 75, 100, 120, 150, 180, 200milímetros.

#2. Selecione de acordo com o tamanho

O tamanho da porta da câmara fria não é fixo, pode ser feito em vários tamanhos de acordo com os requisitos personalizados. Pode ser dividido em manual ou elétrico de uma folha, porta deslizante de folhas duplas ou porta articulada, escolha o tamanho e o tipo apropriado de porta da câmara fria de acordo com a aplicação da câmara fria.

Por exemplo, se uma empilhadeira for necessária para entrar e sair, você deve escolher uma porta elétrica para câmara fria para facilitar a entrada e saída. Para pequena câmara fria, apenas poucas pessoas entram e saem, então pode escolher operar manualmente a porta.

Enquanto isso, quando a instalação, você também deve compreender a localização específica da porta da câmara fria. Se escolher uma porta deslizante, você precisa ter espaço suficiente para colocar o slide.

#3. Selecione de acordo com o material

A moldura da porta da câmara fria pode ser feita de liga de alumínio,aço inoxidável, cor aço ou plástico PVC. O PVC é um mau condutor de calor, que não só pode garantir efetivamente uma temperatura constante, mas também fortalecer a capacidade de carga da moldura da porta e dos trilhos guia. Ainda pode ser usado em baixas temperaturas.

O envoltório da porta da sala fria adota soldagem sem costura de aço inoxidável ou plástico reforçado com fibra de vidro (PRFV) que é impermeável, forte isolamento térmico e resistência à corrosão.

O núcleo interno da porta da câmara fria é geralmente feito de poliuretano (PU) , PIR, ou material XPS. XPS tem boa resistência à umidade, alta resistência à compressão, preço moderado, desempenho estável e longa vida útil. É a melhor escolha para materiais de isolamento de câmaras frigoríficas.

Aplicativo: Câmara fria geral, congelador, câmara frigorífica marítima e outras com temperatura > -40 °C

Equipamento: Moldura de porta de alumínio, corrediça em forma de U de liga de alumínio, Núcleo de PU, maçaneta da porta de aço inoxidável, fechadura de porta de aço inoxidável, alça de empurrar interna.

Função: Dispositivo de fuga Opcional: cinto de aquecimento elétrico de orvalho, pequena porta na porta.

Grossura: 75~300mm ou personalizado.

Tamanho: Personalizado.

Aplicativo: Câmara fria de hospitalidade, congelador, resfriador, câmara frigorífica marinha, indústria alimentícia, indústria médica, e outros com temperatura > -35 °C

Equipamento: Moldura de porta de alumínio, corrediça em forma de U de liga de alumínio, Núcleo de PU, maçaneta da porta de aço inoxidável, fechadura de porta de aço inoxidável, alça de empurrar interna, janela de vidro temperado.

Função: Dispositivo de fuga Opcional: janela de vidro, cinto de aquecimento elétrico de orvalho.

Grossura: 75~300mm ou personalizado.

Tamanho: Personalizado.

Aplicativo: Câmara fria de alimentos, câmara fria civil, planta de processamento de frutos do mar, refeições.

Equipamento: Moldura de porta em aço inoxidável, aço inoxidável / chapa de aço colorida, fechadura de porta importada. A junta da moldura da porta é feita de material de borracha com resistência a baixas temperaturas e forte elasticidade.

Controle de abertura de porta: Botão, puxar corda, anel geomagnético, fotoelétrico, radar.

Opcional: Página de porta simples ou dupla, janela de vidro (Vidro antiembaçante).

Fonte de energia: 220~240 V 50/60 Hz, 380~440 V 50/60 Hz

Grossura: 75~300mm ou personalizado.

Tamanho: Personalizado.

Aplicativo: Fábrica de laticínios, fábrica farmacêutica, fábrica de produtos químicos, armazém de frutas e legumes, hotel.

Equipamento: Moldura de porta em PVC, cor de aço / galvanizado / alumínio / placa de aço inoxidável, coberto com película protetora de PVC, fechadura de porta importada,janela visual (opcional).

Recurso: A fechadura da porta é leve e fácil de reiniciar. A porta mais perto (opcional) pode fortalecer o retorno e fixar a folha da porta. O ângulo de abertura da folha da porta deve ser inferior a 90 grau.

Grossura: 75~200mm ou personalizado.

Tamanho: Personalizado.

Aplicativo: Fábrica de laticínios, fábrica farmacêutica, fábrica de produtos químicos, armazém de frutas e legumes, hotel.

Equipamento: Moldura de porta em PVC/aço inoxidável, cor de aço / galvanizado / alumínio / placa de aço inoxidável, coberto com película protetora de PVC, fechadura de porta importada,janela visual (opcional).

Recurso: A fechadura da porta é leve e fácil de reiniciar. O ângulo de abertura da folha da porta deve ser inferior a 90 grau.

Opcional: Página de porta simples ou dupla,fecho de porta que pode fortalecer o retorno e fixar a folha da porta.

Grossura: 75~200mm ou personalizado.

Tamanho: Personalizado.

Aplicativo: Câmara fria com entradas e saídas frequentes. Fabricação, quartos limpos, grandes instalações industriais, edifícios hangares,etc. Especialmente a câmara fria para distribuição. Como KFC, Pizza Hut, Supermercado.

Recurso: Com dispositivo automático de abertura e fechamento (geomagnético ou radar). Rolamento de PVC com cortina de borracha resistente a impactos. Ideal para passagem de empilhadeiras e equipamentos pesados.

Controle de abertura de porta: Puxe a corda, botão, remoto ou manual. A velocidade de elevação automática é de 1,2 ~ 2,5 m/s.

Fonte de energia: 220~240 V 50/60 Hz, 380~440 V 50/60 Hz

Grossura: 12~20mm ou personalizado.

Tamanho: Personalizado.

| Nome do componente | Características |

|---|---|

| Painel da porta | Estrutura completamente fechada sem moldura, espuma inteira de poliuretano e painel, painel é feito de aço colorido, chapa de aço inoxidável ou alumínio, tem bom desempenho de isolamento térmico. |

| Moldura da porta | Feito de liga de alumínio ou aço em forma de C coberto por aço inoxidável, aparência arrumada e durável, não como moldura de porta de madeira que é fácil corrosão. |

| Dispositivo de trilho guia | Feito de liga de alumínio, seu dispositivo de roda guia atua em conjunto com a roda de compressão para que a porta possa se separar da moldura da porta ao abrir e pressionar contra a moldura da porta e o chão ao fechar. |

| Sistema de controle elétrico | Adote um redutor usado na turbina e uma correia síncrona para transferir o movimento. Enquanto isso, possui embreagem eletromagnética para realizar automaticamente a conversão entre pad e manual, o que garante a segurança da porta elétrica. |

| Faixa de vedação | Resistência a baixas temperaturas, resistência ao óleo, feito de EPDM altamente elástico, temperatura ambiente: -50°C ~ +130 °C pode funcionar corretamente. |

| Fio de aquecimento | Temperatura constante automática, 220V ou 36V, aquecimento de baixa tensão. |

| Acessórios | As peças metálicas do painel da porta são de aço inoxidável de alta precisão. |

| Espessura da porta | 75/100/150/200milímetros |

| Nome do componente | Características |

|---|---|

| Painel da porta | Material e painel de aço inoxidável/alumínio/aço combinam-se com a caixa, com espuma integrada de poliuretano, sem fenômeno de ponte fria, desempenho extremamente bom de preservação de calor. |

| Moldura da porta | Possui faixa de aquecimento elétrico para controle de temperatura próprio, não há necessidade de dispositivo de controle de temperatura ou fonte de alimentação de interruptor manual. |

| Faixa de vedação | Listras magnéticas embutidas em plástico flexível, pode modificar até mesmo pequenos erros causados pela fabricação. |

| Dispositivo de fuga | Com dispositivos de fuga e segurança, e também possui alça interna. |

| Acessórios | Use aço inoxidável ou material de liga de zinco de alta resistência. |

| Espessura da porta | 50/75/100/150/200milímetros |

Perguntas frequentes sobre a porta da sala fria

Principais recursos da porta da câmara fria incluídos: isolamento para minimizar a transferência de temperatura, vedações herméticas para evitar vazamento de ar, durabilidade para suportar o uso repetido, e um mecanismo de bloqueio para segurança.

A porta da câmara frigorífica utiliza materiais de isolamento e mecanismos de vedação para minimizar a transferência de calor e manter a temperatura desejada dentro da câmara frigorífica.

A Speedway está comprometida com a qualidade em todos os aspectos do nosso negócio - nosso pessoal, processos e produtos. Chamamos isso de ‘Padrão VELOCIDADE'.

Vedações comumente usadas na porta da câmara fria incluídas: juntas de compressão, juntas magnéticas, ou selos infláveis. Estas vedações garantem um fechamento hermético e minimizam a infiltração de ar.

Congratulamo-nos com qualquer pedido de amostra antes da compra em grande quantidade, isso significa que 1pc é aceitável. Para pedido em massa, a quantidade é de 30 unidades no total.

A manutenção regular envolve: limpando as superfícies da porta, verificar e substituir vedações ou juntas danificadas, inspecionar e lubrificar dobradiças e peças móveis, e garantindo que a porta funcione suavemente.

A instalação adequada envolve: seguindo as orientações do fabricante, garantindo que a porta esteja aprumada e nivelada, selando corretamente o perímetro, e testando a porta para operação adequada.

Temos fábrica própria para produzir os principais produtos para portas de câmaras frigoríficas, mas também negociamos outros produtos relacionados porque temos recursos para fornecer boa qualidade e serviço.

Sim,Nós temos 3 engenheiros seniores, 10 profissional r & equipe D, 55 pessoal de produção profissional.

Os recursos de segurança incluem: mecanismos de liberação de emergência, sensores de segurança para detectar obstruções, e alarmes de aviso para indicar o movimento da porta.

A vida útil da porta da câmara fria pode variar dependendo de fatores como: uso, manutenção, e condições ambientais. Geralmente, portas bem conservadas podem durar de 8 a 10 anos.

Apoiamos o pagamento através de transferência bancária, como T/T, L/C, Western Union. Também aceita pagamento Paypal para pedido de peça de amostra.

Sim, as portas da sala fria podem ser personalizadas para caber em tamanhos específicos, configurações, e requisitos de temperatura do armazenamento refrigerado.

Sim, mas é muito importante consultar um técnico profissional especializado em reparos de portas de câmaras frigoríficas para avaliar a extensão dos danos e fornecer soluções adequadas.

Sim, nós fizemos. Nossa fábrica tem interior 100% inspeção para cada unidade antes do carregamento, também pode fazer o relatório de teste legal para cada remessa. O que mais, pode convidar SGS / TUV / Inspeção BV de acordo com os clientes’ solicitar, mas os clientes devem pagar a taxa de teste.

Primeiro, precisamos iniciar o negócio para nos entendermos, se as coisas correrem bem e você atender aos nossos “pedido de distribuidor”, então assinaremos o contrato formal e o acordo para garantir seus direitos em seu mercado.

Contate nosso vendedor para mais detalhes por favor.

Seja nosso parceiro para aumentar a reputação da sua marca, obtenha uma experiência impressionante para que seus clientes se lembrem de você por toda a vida, e ajudá-lo a se destacar no mercado competitivo !

Pesquisar produto relacionado

E-mail:

sales@cn-beyond.com

cn-beyond@hotmail.com