In de wereld van HVACR (Verwarming, Ventilatie, Airconditioning, en koeling) systemen, koelmiddeldistributeur speelt een cruciale maar vaak over het hoofd geziene rol. Als u zoekt naar “wat is een koelmiddelverdeler,” “hoe werkt een koelmiddelverdeler,” of “soorten koelmiddelverdelers,” deze gids behandelt alles wat u moet weten.

Of u nu een HVACR-technicus bent, ingenieur, of huiseigenaar die problemen met uw AC-unit oplost, Het begrijpen van de koelmiddelverdeler kan de systeemefficiëntie optimaliseren, kostbare storingen voorkomen, en zorgen voor een gelijkmatige koeling.

We zullen het stap voor stap opsplitsen, van de basis tot geavanceerde probleemoplossing.

Inleiding tot de koelmiddeldistributeur

Koelmiddelverdeler is een essentieel mechanisch apparaat in koeling En airconditioning systemen, specifiek gebruikt om vloeibaar en dampvormig koelmiddel gelijkmatig te verspreiden over meerdere parallelle circuits in een verdamperspiraal.

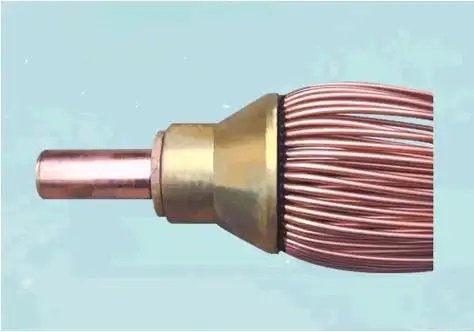

Vaak vergeleken met a “douchekop” voor koelmiddel, het zorgt voor een evenwichtige stroom, het voorkomen van hotspots of inefficiënties die kunnen leiden tot ongelijkmatige koeling of systeembelasting.

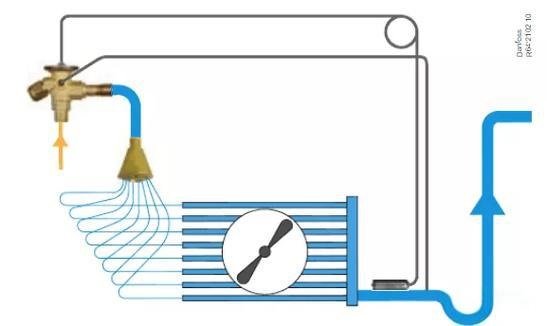

In HVACR-opstellingen, de verdeler zit tussen het thermostatische expansieventiel (TXV) en de verdamper, omgaan met verzadigd koelmiddel (een mengsel van vloeistof en gas) om een optimale warmteopname te bevorderen.

Waarom doet dit er toe?

Een slechte distributie kan ervoor zorgen dat de spoel bevriest, verminderde efficiëntie, of schade aan de compressor.

Voor degenen die vragen stellen “koelmiddelverdelerfunctie,” het is in wezen de equalizer die de energieoverdracht maximaliseert, verbetering van de algehele systeemprestaties met maximaal 20~30% in verdampers met meerdere circuits. Deze gids demystificeert het voor zowel beginners als professionals.

Geschiedenis en evolutie van koelmiddeldistributeurs

Het verhaal van de koelmiddeldistributeur weerspiegelt de bredere evolutie van koelmiddelen en HVACR-technologie, dateert uit het einde van de 19e eeuw, toen mechanische koeling opkwam. In 1876, De Duitse ingenieur Carl von Linde patenteerde processen voor het vloeibaar maken van gas, de basis leggen voor moderne systemen. Vroege distributeurs waren rudimentair, vertrouwend op eenvoudige spruitstukken zonder nauwkeurig mengen.

Tegen de jaren twintig, met de uitvinding van chloorfluorkoolwaterstoffen (CFK's) van Thomas Midgley, distributeurs zijn geëvolueerd om meer vluchtige koelmiddelen zoals R12 te verwerken. In de jaren zeventig en tachtig werd er vooruitgang geboekt op het gebied van milieuproblemen, verschuiving van CFK’s naar HCFK’s (bijv., R22). Distributeurs hebben mondstukken ingebouwd voor een betere snelheidsregeling, het aanpakken van problemen zoals ongelijkmatige stroming in grotere spoelen.

Vandaag, met de geleidelijke afschaffing van R22 onder het Montreal Protocol en de opkomst van HFK's zoals R410a, R32, R404, enz. moderne distributeurs zijn voorzien van verwisselbare openingen en venturi-ontwerpen voor een laag GWP (Potentieel voor opwarming van de aarde) koelmiddelen. Toekomstige trends wijzen op milieuvriendelijke aanpassingen voor op CO2 gebaseerde systemen, nadruk op duurzaamheid in de HVACR-evolutie.

Hoe een koelmiddeldistributeur werkt

Begrip “hoe een koelmiddelverdeler werkt” begint met de plaatsing ervan in de koelcyclus. Nadat de TXV koelmiddel in de verdeler doseert, het apparaat gebruikt een mondstuk om de stroom te versnellen, waardoor een drukval ontstaat die vloeistof- en dampfasen homogeen mengt.

Dit hogesnelheidsmengsel vertakt zich vervolgens in capillaire buizen of circuits, waardoor een gelijkmatige verdamping over de spoel wordt gegarandeerd.

Belangrijke stappen in de werking:

- Inlaatfase: Verzadigd koelmiddel komt met gematigde druk uit de TXV.

- Mengkamer: Interne schotten of venturi-effecten brengen het koelmiddel in beroering, bereiken 50-70% dampkwaliteit voor uniforme verdeling.

- Outletdistributie: Buizen voeden de verdamper, waar koelmiddel warmte absorbeert, het verandert in damp voordat het terugkeert naar de compressor.

- Drukdynamiek: De juiste maatvoering zorgt voor een 5-10 psi-daling, stratificatie voorkomen (vloeibare bundeling).

In verdampers met meerdere circuits, dit voorkomt “slechte distributie,” waar sommige secties zich te veel voeden, terwijl andere verhongeren, wat tot inefficiënties leidt. Voor visuele leerlingen, Stel je het voor als een verkeersagent die koelmiddel regelt “auto's” om jam te voorkomen.

Soorten koelmiddeldistributeurs

Niet alle koelmiddelverdelers zijn gelijk; de selectie hangt af van de systeemgrootte, soort koelmiddel, en verdamperontwerp. Hier vindt u een overzicht van veelvoorkomende typen:

| Type | Beschrijving | Beste voor | Belangrijkste kenmerken |

|---|---|---|---|

| Mondstuk | Maakt gebruik van verwisselbare openingen om de stroom te regelen; lijkt op een geperforeerde dop | Flexibele toepassingen zoals commerciële AC-units | Verstelbare maat, eenvoudige retrofits; kan goed omgaan met R-410A |

| Venturi-Flo | Unit uit één stuk met venturimondstuk voor natuurlijk mengen via snelheidsverhoging | Systemen met hoge capaciteit | Geen losse onderdelen, vermindert verstopping; ideaal voor R-134a |

| RD (Vloeistofdistributeur) | Danfoss-stijl met uniforme aftakking voor verdampers met meerdere secties | Industriële koeling | Compatibel met R-404A, R-407C; zorgt voor lage holtefracties |

| Flensinlaat (bijv., Soorten 1109/1124) | Kan rechtstreeks op de TXV-uitlaat worden vastgeschroefd met mannelijke flens | Sporlan-geïntegreerde systemen | Compact, trillingsbestendig; voor kleinere wooneenheden |

| Openingsverdelers | Basic douchekopachtig ontwerp met vaste gaten | Budgetinstellingen | Eenvoudig, kosteneffectief; gebruikelijk bij oudere R-22-systemen |

Kies op basis van koudemiddel (bijv., R410a heeft een hogere druktolerantie nodig) en aantal circuits - tot 12 voor grote spoelen.

Belang in HVACR-systemen

Een koelmiddelverdeler is niet onderhandelbaar wat betreft efficiëntie in moderne HVACR. Het bevordert een uniforme warmteoverdracht, het verminderen van het energieverbruik door ervoor te zorgen dat elk spoelgedeelte het koelmiddel optimaal verdampt. Zonder, systemen lijden:

- Ongelijkmatige koeling: Warme/koude plekken in kamers.

- Overbelasting compressor: Overstroming door onevenwichtige stroming.

- Efficiëntieverliezen: Tot aan 15% hogere energierekening.

In commerciële omgevingen, het verlengt de levensduur van apparatuur door thermische stress te minimaliseren. Voor milieubewuste zoekopdrachten zoals “energiebesparing van de koelmiddelverdeler,” merk op dat het overgangen met een laag GWP ondersteunt, in lijn met de EPA-regelgeving.

Installatiehandleiding voor koelmiddelverdelers

Een juiste installatie van de koelmiddelverdeler is van cruciaal belang om lekken of beperkingen te voorkomen. Volg altijd de specificaties van de fabrikant (bijv., Parker Sporlan-richtlijnen). Gereedschap nodig: momentsleutel, stroom, soldeerbrander.

Stap voor stap:

- Bereid het systeem voor: Koelmiddel afvoeren; isoleer de verdamper.

- Monteer de distributeur: Plaats horizontaal boven de spoelkop, 6-12 inch van TXV. Zet vast met klemmen.

- Sluit de inlaat aan: Soldeer of schroef vast aan de TXV-uitlaat; gebruik ASC (Automatische distributeurselectie) indien nodig voor het vasthouden van de spuitmonden.

- Bevestig uitlaatbuizen: Op lengte gesneden (overeenkomen met spoelcircuits); flare eindigt en verbindt met vakbonden. Zorg voor gelijke lengtes voor evenwicht.

- Isoleer en test: Wikkel met schuim; druktest op 300 psi, controleer vervolgens de lekkage met stikstof.

- Kosten en commissie: Voeg koelmiddel toe; oververhitting in de gaten houden (8-12°F doel).

Voor Tip: Voor R410a, gebruik langere buizen voor een betere menging. Raadpleeg de lokale codes voor de veiligheid.

Onderhoudstips voor een langere levensduur

Regelmatig onderhoud van de koelmiddelverdeler voorkomt dit 80% van mislukkingen. Plan halfjaarlijkse controles.

- Visuele inspectie: Zoek naar corrosie, losse fittingen, of olieresten die op lekken duiden.

- Schone openingen: Spoel met oplosmiddel als het verstopt is; vermijd schuurmiddelen.

- Controleer de slangen: Zorg ervoor dat er geen knikken zijn; vervangen als de diameter kleiner is.

- Systeembrede afstemming: Controleer de TXV-functie en oververhitting; Pas de verdeler aan als er onevenwichtigheden in de stroom worden gedetecteerd.

- Zuiverheid van koelmiddel: Gebruik filters om vuil te voorkomen; jaarlijks veranderen.

Voor “Reiniging van de koelmiddelverdeler,” Voor de meeste soorten volstaat een eenvoudige stikstofdoorblaas. Dit verlengt de levensduur 10+ jaren.

Veelvoorkomende problemen en probleemoplossing voor koelmiddeldistributeurs

Het oplossen van problemen met de koelmiddeldistributie brengt vaak beperkingen of storingen aan het licht.

Symptomen: Lage zuigdruk, bevriezing van de spoel, of ongelijke temperaturen.

| Probleem | Oorzaken | Probleemoplossen |

|---|---|---|

| Ongelijke verdeling | Verstopte spuitmond of ongelijke buislengtes | Meet stromen; de grootte van de openingen wijzigen; buizen egaliseren |

| Bevriezen | Lage kosten of beperking | Controleer oververhitting; ontdooien en opladen; inspecteren op vuil |

| Lekken | Gesoldeerde verbindingsfout | Soldeer repareren of vervangen; gebruik 45% zilver soldeer |

| Slecht mengen | Versleten venturi | Distributeur vervangen; snelheidsdaling testen |

Gebruik meters: Streef naar oververhitting van 5-10°F. Indien volhardend, bel een professional om schade aan de compressor te voorkomen.

Conclusie

Het beheersen van de koelmiddelverdeler maakt efficiënt, betrouwbare HVACR-prestaties. Van de venturi-aangedreven mechanica tot de veelzijdigheid van het mondstuktype, dit onderdeel zorgt ervoor dat uw systeem soepel werkt.

Herinneren: Installeer correct, ijverig onderhouden, en problemen proactief oplossen. Terwijl koelmiddelen evolueren naar duurzaamheid, distributeurs zullen zich aanpassen en op de hoogte blijven via bronnen als ASHRAE.

Voor meer informatie “beste praktijken voor koelmiddeldistributeurs,” Maak een bladwijzer van deze handleiding.

Eventuele opmerkingen?

Welkom laat een bericht achter of repost.