One-stop-OEM & ODM-oplossingspartner

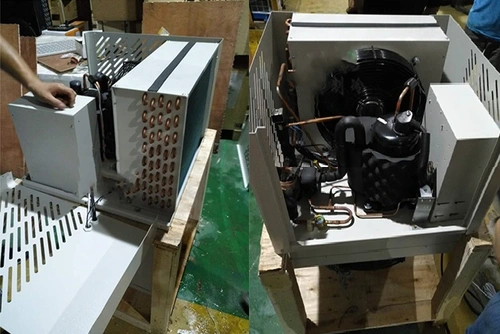

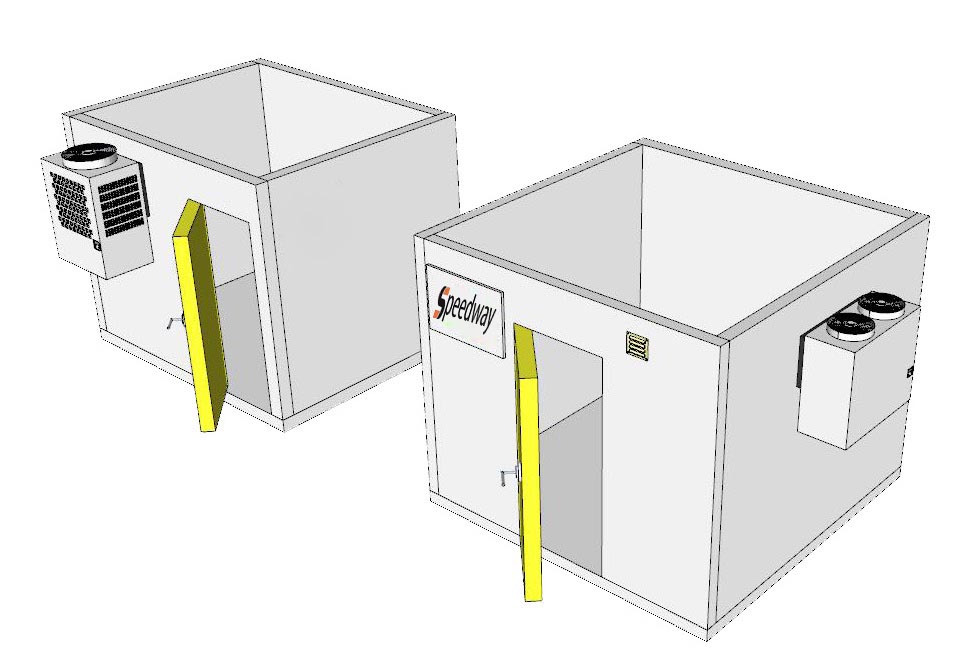

Aangepaste fabrikant en leverancier van monoblock-koelunits in China

Wij vervaardigen monoblock-koelunits van 0,5 ~ 5,0 pk (zowel omvormer als niet-omvormer) met een betere prijs. Ondertussen bieden ontwerp, installatie, inbedrijfstelling, onderhoud, technische ondersteuning en one-stop-oplossing voor uw project, Contacteer ons nu !