Collegare correttamente cavi e fili è essenziale per garantire la sicurezza e l'efficienza del sistema di refrigerazione, e anche altri sistemi elettrici. Sia che tu stia lavorando a un progetto fai -da -te, riparazione dell'appliance, o installazione di nuovi cablaggi elettrici, Comprendere i vari metodi per collegare cavi e fili è cruciale.

Questa guida fornisce una panoramica dei modi più comuni per stabilire queste connessioni, comprese le loro applicazioni, Vantaggi, e svantaggi.

Alla fine, saprai come scegliere il metodo di connessione giusto per le tue esigenze specifiche.

Metodi comuni per collegare cavi e fili

SPLICE CRIMP

Descrizione: Una giunzione Crimp è un connettore che unisce due fili comprimendo il connettore sui fili, Creazione di una connessione elettrica sicura. È un metodo semplice e ampiamente usato.

Strumenti richiesti:

-

Spogliarellista

-

Strumento di crimpatura

Come usare:

-

Spogliare l'isolamento dalle estremità dei fili da unire.

-

Inserire i fili nel connettore di giunzione Crimp.

-

Usa lo strumento di crimpatura per comprimere il connettore sui fili, Garantire una connessione stretta.

Applicazioni: Comunemente usato nelle installazioni elettriche, Cablaggio automobilistico, e altre impostazioni in cui necessitano di una connessione affidabile e rapida.

Vantaggi:

-

Facile da usare

-

Richiede strumenti minimi

-

Fornisce una connessione sicura

Svantaggi:

-

Non impermeabile

-

Potrebbe non essere adatto per ambienti ad alta vibrazione

Maniche di saldatura

Descrizione: Le maniche di saldatura sono connettori con un rivestimento interno di saldatura che si scioglie quando riscaldato, Creazione di un giunto saldato tra i fili. Includono anche tubi di shrink di calore per l'isolamento.

Strumenti richiesti:

-

Spogliarellista

-

Pistola termica o saldatura

Come usare:

-

Strizza l'isolamento dalle estremità del filo.

-

Far scorrere la manica di saldatura su un filo.

-

Inserire il secondo filo nella manica.

-

Applicare il calore alla manica, sciogliendo la saldatura interna per unirsi ai fili.

-

Consenti alla connessione di raffreddare e solidificare.

Applicazioni: Usato nell'aerospaziale, settore automobilistico, e applicazioni industriali in cui necessitano di una connessione permanente e robusta.

Vantaggi:

-

Fornisce un forte, connessione permanente

-

Più affidabile della crimpatura giunta in determinati ambienti

Svantaggi:

-

Richiede abilità ed esperienza

-

Non riutilizzabile

-

Richiede tempo

Dadi di filo

Descrizione: I dadi di filo sono connettori a torsione che fissano i fili ruotando il connettore sulle estremità spogliate, comunemente usato nel cablaggio residenziale.

Strumenti richiesti:

-

Spogliarellista

-

Cacciavite (per alcuni tipi)

Come usare:

-

Strizza l'isolamento dalle estremità del filo.

-

Torci i fili insieme (opzionale per alcune applicazioni).

-

Avvitare il dado del filo sui fili intrecciati, Garantire che tutti i fili siano completamente all'interno.

Applicazioni: Ampiamente utilizzato nel cablaggio elettrico residenziale per collegare più fili nelle scatole di giunzione.

Vantaggi:

-

Molto facile da usare

-

Non costoso

-

Ampiamente disponibile

Svantaggi:

-

Non adatto per le posizioni esterne o bagnate a meno che non sia impermeabile

-

Può allentare nel tempo se non installato correttamente

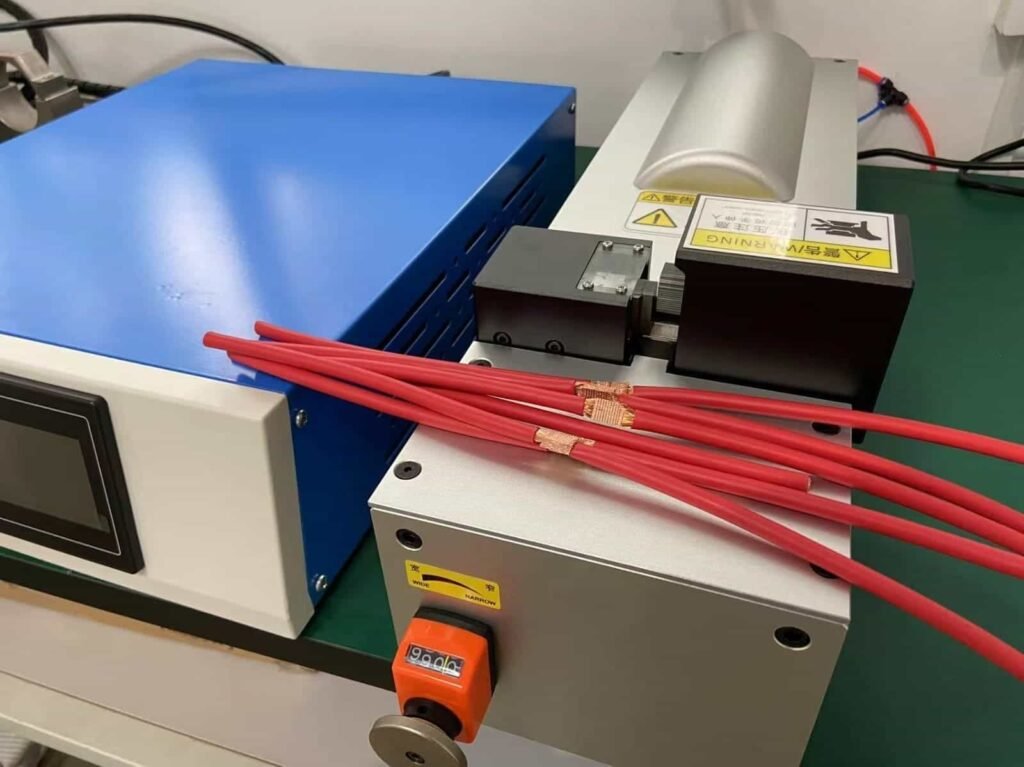

Saldatura ad ultrasuoni

Descrizione: La saldatura ad ultrasuoni utilizza vibrazioni ad alta frequenza per unire i fili senza fondere l'isolamento, Creare un forte, connessione pulita.

Strumenti richiesti:

-

Welding Machine ad ultrasuoni

Come funziona:

-

Metti i fili nella saldatura.

-

La macchina applica vibrazioni e pressione ad ultrasuoni, Saldatura dei fili insieme generando calore all'interfaccia.

Applicazioni: Utilizzato nell'automotivo, aerospaziale, e produzione di elettronica per collegamenti affidabili.

Vantaggi:

-

Crea un pulito, saldatura forte

-

Nessun danno da calore alle aree circostanti

-

Processo rapido

Svantaggi:

-

Richiede attrezzature costose

-

Non è adatto a tutti i tipi di filo

Connettori a filo push-in

Descrizione: I connettori a filo push-in consentono di inserire i fili direttamente nel connettore, Spesso con un guscio chiaro per la verifica visiva.

Strumenti richiesti:

-

Spogliarellista

Come usare:

-

Strizza l'isolamento dalle estremità del filo.

-

Spingere i fili nel connettore fino a bloccarsi in posizione.

Applicazioni: Utilizzato nel cablaggio residenziale, Soprattutto in spazi stretti, poiché sono compatti.

Vantaggi:

-

Rapido e facile da installare

-

Non è richiesta la torsione

-

Verifica visiva della connessione

Svantaggi:

-

Potrebbe non essere così sicuro se non installato correttamente

-

Limitato a specifici indicatori di filo

Terminali a vite

Descrizione: I terminali a vite si trovano su dispositivi come interruttori di luce e prese, dove i fili sono fissati facendoli girare attorno a una vite.

Strumenti richiesti:

-

Spogliarellista

-

Cacciavite

Come stabilire la connessione:

-

Spogliare l'isolamento dall'estremità del filo.

-

Formare un ciclo in senso orario con il filo spogliato.

-

Agganciare il ciclo attorno al terminale a vite.

-

Stringere la vite per fissare il filo.

Applicazioni: Standard in installazioni elettriche residenziali e commerciali.

Vantaggi:

-

Semplice e diretto

-

Facile da disconnettere e riconnettersi

Svantaggi:

-

Può allentare nel tempo se non serrato correttamente

-

Non ideale per le aree ad alta vibrazione

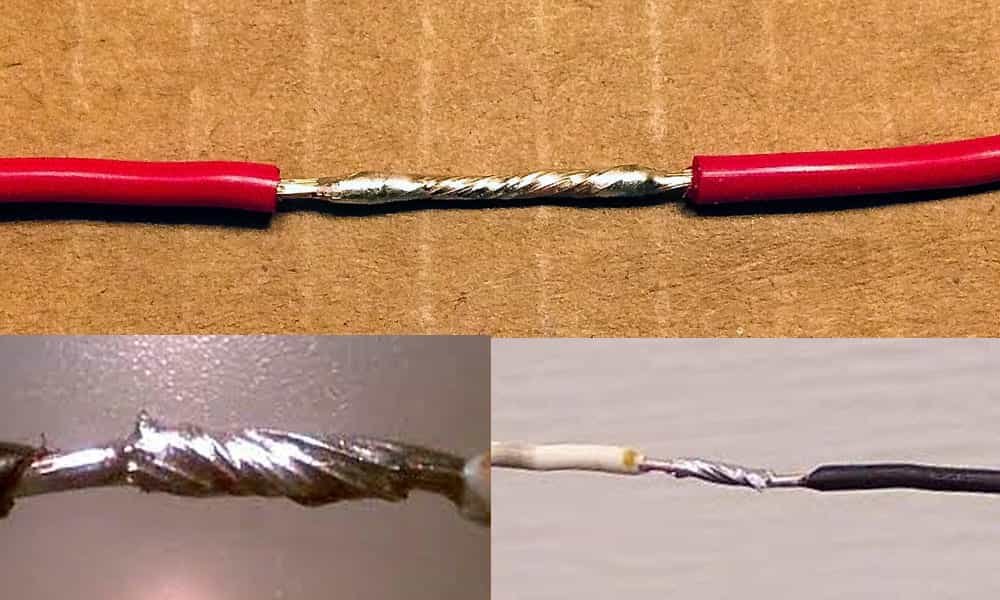

Saldatura

Descrizione: La saldatura prevede lo scioglimento della saldatura per unire i fili, Creazione di una connessione elettrica permanente.

Strumenti e materiali necessari:

-

Spogliarellista

-

Saldatura

-

Saldare

-

Tubo di rimpasto di calore (opzionale)

Guida passo-passo:

-

Strizza l'isolamento dalle estremità del filo.

-

Pulire le estremità del filo se necessario.

-

Stagno il saldatore applicando una piccola quantità di saldatura alla punta.

-

Tieni insieme i fili e applica il saldatura al giunto.

-

Applicare la saldatura al giunto, permettendolo di fluire attorno ai fili.

-

Rimuovere il saldatore e lasciare raffreddare l'articolazione.

-

Ispezionare l'articolazione; Dovrebbe essere lucido e liscio.

-

Applicare i tubi di rimpasto di calore per l'isolamento, se necessario.

Applicazioni: Utilizzato in elettronica, settore automobilistico, e le applicazioni richiedevano connessioni permanenti.

Vantaggi:

-

Forte, connessione permanente

-

Adatto per ambienti ad alta vibrazione

Svantaggi:

-

Richiede abilità e pratica

-

Richiede tempo

-

Il calore può danneggiare componenti sensibili

Connettori speciali

Connettori sotterranei/impermeabili

Descrizione: Questi connettori proteggono i collegamenti dei fili dall'umidità, soprattutto per uso esterno o sotterraneo.

Applicazioni: Sistemi di irrigazione, illuminazione esterna, sistemi di contenimento degli animali domestici.

Vantaggi:

-

Protezione impermeabile

-

Durevole in ambienti difficili

Svantaggi:

-

Più costoso

-

Può richiedere strumenti specifici

Connettori PCB (per esempio., RJ45)

Descrizione: Connettori PCB, Come RJ45, Collegare i fili ai circuiti stampati, comunemente usato per i cavi Ethernet.

Strumenti richiesti:

-

Strumento di crimpatura (per RJ45)

Come usare (per RJ45):

-

Strizza il cavo Ethernet per esporre i fili.

-

Disporre i fili nell'ordine corretto.

-

Inserire i fili nel connettore RJ45.

-

Aggrappa il connettore sul cavo.

Applicazioni: Networking, telecomunicazioni.

Vantaggi:

-

Standardizzato per applicazioni specifiche

-

Facile da installare con strumenti adeguati

Svantaggi:

-

Specifico per determinati cavi e applicazioni

Considerazioni sulla sicurezza

La sicurezza è fondamentale quando si lavora con i fili elettrici. Le considerazioni chiave includono:

-

Disattivare il potere: Assicurarsi sempre che il potere sia spento prima di lavorare, Utilizzando un tester di tensione senza contatto.

-

Isolamento adeguato: Isolare tutte le connessioni per prevenire cortocircuiti e shock.

-

Connessioni sicure: Le connessioni sciolte possono causare arco e incendi; Assicurarsi che tutte le connessioni siano strette.

-

Scegli metodi appropriati: Seleziona metodi basati sull'ambiente, vibrazione, e bisogni di permanenza.

-

Consultare i professionisti: Per progetti complessi o ad alta tensione, Assumi un elettricista autorizzato.

Tabella di confronto dei metodi di connessione

|

Metodo |

Strumenti richiesti |

Applicazioni |

Vantaggi |

Svantaggi |

|---|---|---|---|---|

|

SPLICE CRIMP |

Spogliarellista, strumento di crimpatura |

Elettrico, settore automobilistico |

Facile, strumenti minimi, sicuro |

Non impermeabile, sensibile alle vibrazioni |

|

Maniche di saldatura |

Spogliarellista, Pistola da calore/saldatura |

Aerospaziale, settore automobilistico |

Forte, permanente |

Richiede abilità, non riutilizzabile |

|

Dadi di filo |

Spogliarellista, cacciavite |

Cablaggio residenziale |

Facile, economico, ampiamente disponibile |

Non per luoghi bagnati, può allentare |

|

Saldatura ad ultrasuoni |

Welding Machine ad ultrasuoni |

Automobile, elettronica |

Pulito, forte, veloce |

Attrezzatura costosa, Uso limitato |

|

Connettori push-in |

Spogliarellista |

Cablaggio residenziale |

Presto, Nessuna torsione, compatto |

Meno sicuro se improprio, calibro limitato |

|

Terminali a vite |

Spogliarellista, cacciavite |

Dispositivi elettrici |

Semplice, riconnettibile |

Può allentare, sensibile alle vibrazioni |

|

Saldatura |

Spogliarellista, saldatura, saldare |

Elettronica, settore automobilistico |

Forte, permanente |

Abilità ad alta intensità, richiede tempo |

|

Connettori impermeabili |

Varia |

All'aperto, metropolitana |

Impermeabile, durevole |

Costoso, specifico per gli strumenti |

|

Connettori PCB (RJ45) |

Strumento di crimpatura |

Networking |

Standardizzato, Facile con gli strumenti |

Specifico dell'applicazione |

Conclusione

Collegamento di cavi e fili richiede efficacemente la comprensione dei vari metodi disponibili, Dai semplici dadi a filo alla saldatura ad ultrasuoni avanzati. Ogni metodo ha vantaggi unici ed è adatto a applicazioni specifiche.

Seguendo questa guida e dando la priorità alla sicurezza, Puoi garantire connessioni elettriche affidabili e sicure per i tuoi progetti. Fare riferimento alle risorse collegate per ulteriori dettagli e affrontare con fiducia le tue attività di cablaggio.

Eventuali commenti?

Benvenuto, lascia un messaggio o ripubblicalo.