Nel mondo dell'HVACR (Riscaldamento, Ventilazione, Aria condizionata, e Refrigerazione) sistemi, Il distributore di refrigerante svolge un ruolo cruciale ma spesso trascurato. Se stai cercando “cos'è un distributore di refrigerante,” “come funziona un distributore di refrigerante,” O “tipi di distributori di refrigerante,” questa guida copre tutto ciò che devi sapere.

Che tu sia un tecnico HVACR, ingegnere, o il proprietario della casa che risolve i problemi dell'unità AC, comprendere il distributore del refrigerante può ottimizzare l'efficienza del sistema, prevenire costosi guasti, e garantire un raffreddamento uniforme.

Lo analizzeremo passo dopo passo, dalle nozioni di base alla risoluzione avanzata dei problemi.

Introduzione al distributore di refrigerante

Il distributore di refrigerante è un dispositivo meccanico vitale refrigerazione E aria condizionata sistemi, utilizzato specificatamente per disperdere uniformemente il refrigerante liquido e vapore su più circuiti paralleli in una serpentina dell'evaporatore.

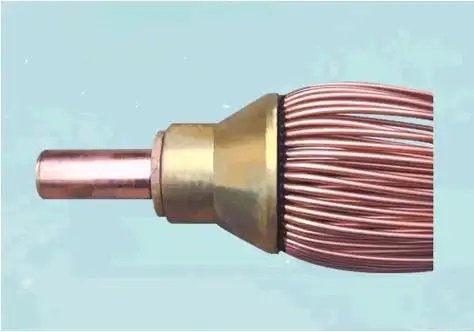

Spesso paragonato a a “soffione della doccia” per refrigerante, garantisce un flusso equilibrato, prevenendo punti caldi o inefficienze che potrebbero portare a un raffreddamento non uniforme o a sollecitazioni del sistema.

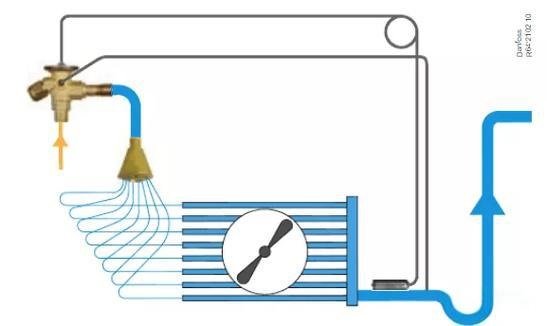

Nelle configurazioni HVACR, il distributore si trova tra la valvola di espansione termostatica (TXV) e l'evaporatore, maneggiare il refrigerante saturo (una miscela di liquido e gas) per favorire un assorbimento ottimale del calore.

Perché è importante??

Una cattiva distribuzione può causare il congelamento della bobina, efficienza ridotta, o danni al compressore.

Per coloro che hanno domande “funzione distributore di refrigerante,” è essenzialmente l’equalizzatore che massimizza il trasferimento di energia, migliorare le prestazioni complessive del sistema fino al 20~30% negli evaporatori multicircuito. Questa guida lo demistifica sia per i principianti che per i professionisti.

Storia ed evoluzione dei distributori di refrigerante

La storia del distributore di refrigerante rispecchia l'evoluzione più ampia dei refrigeranti e della tecnologia HVACR, risalente alla fine del XIX secolo quando emerse la refrigerazione meccanica. In 1876, L'ingegnere tedesco Carl von Linde brevettò il processo di liquefazione del gas, gettare le basi per i sistemi moderni. I primi distributori erano rudimentali, basandosi su varietà semplici senza miscelazione precisa.

Negli anni '20, con l'invenzione dei clorofluorocarburi (CFC) di Thomas Midgley, i distributori si sono evoluti per gestire refrigeranti più volatili come l'R12. Gli anni ’70 e ’80 videro progressi nel contesto delle preoccupazioni ambientali, passaggio dai CFC agli HCFC (per esempio., R22). I distributori hanno incorporato ugelli per un migliore controllo della velocità, affrontare problemi come il flusso irregolare nelle bobine più grandi.

Oggi, con l’eliminazione graduale dell’R22 ai sensi del Protocollo di Montreal e l’aumento degli HFC come l’R410a, R32, R404, eccetera. i distributori moderni sono dotati di orifizi intercambiabili e design Venturi per un basso GWP (Potenziale di riscaldamento globale) refrigeranti. Le tendenze future indicano adattamenti ecologici per i sistemi basati sulla CO2, enfatizzare la sostenibilità nell’evoluzione dell’HVACR.

Come funziona un distributore di refrigerante

Comprensione “come funziona un distributore di refrigerante” inizia con il suo inserimento nel ciclo frigorifero. Dopo il TXV dosa il refrigerante nel distributore, il dispositivo utilizza l'ugello per accelerare il flusso, creando una caduta di pressione che mescola omogeneamente la fase liquida e quella vapore.

Questa miscela ad alta velocità si ramifica quindi in tubi o circuiti capillari, garantendo un'evaporazione uniforme attraverso la batteria.

Passaggi chiave del funzionamento:

- Fase di ingresso: Il refrigerante saturo entra dalla TXV a pressione moderata.

- Camera di miscelazione: I deflettori interni o gli effetti Venturi agitano il refrigerante, raggiungimento 50-70% qualità del vapore per una distribuzione uniforme.

- Distribuzione outlet: I tubi alimentano l'evaporatore, dove il refrigerante assorbe calore, trasformandosi in vapore prima di ritornare al compressore.

- Dinamica della pressione: Il dimensionamento corretto mantiene a 5-10 calo PSI, prevenendo la stratificazione (ristagno di liquidi).

Negli evaporatori multicircuito, questo impedisce “cattiva distribuzione,” dove alcune sezioni si nutrono eccessivamente mentre altre muoiono di fame, portando a inefficienze. Per studenti visivi, immaginatelo come un vigile urbano che dirige il refrigerante “automobili” per evitare inceppamenti.

Tipi di distributori di refrigerante

Non tutti i distributori di refrigerante sono uguali: la scelta dipende dalle dimensioni del sistema, Tipo di refrigerante, e progettazione dell'evaporatore. Ecco una ripartizione dei tipi comuni:

| Tipo | Descrizione | Ideale per | Caratteristiche principali |

|---|---|---|---|

| Ugello | Utilizza orifizi intercambiabili per controllare il flusso; assomiglia ad un cappuccio perforato | Applicazioni flessibili come le unità AC commerciali | Taglia regolabile, facili retrofit; gestisce bene l'R-410A |

| Venturi-Flo | Unità monopezzo con ugello Venturi per una miscelazione naturale tramite aumento di velocità | Sistemi ad alta capacità | Nessuna parte sciolta, riduce l'intasamento; ideale per R-134a |

| RD (Distributore di liquidi) | Stile Danfoss con ramificazione uniforme per evaporatori a più sezioni | Refrigerazione industriale | Compatibile con R-404A, R-407C; garantisce frazioni a basso vuoto |

| Ingresso flangiato (per esempio., Tipi 1109/1124) | Si fissa direttamente all'uscita TXV con flangia maschio | Sistemi integrati Sporlan | Compatto, resistente alle vibrazioni; per le unità abitative più piccole |

| Distributori di orifizi | Design semplice simile a un soffione con fori fissi | Configurazioni del budget | Semplice, conveniente; comune nei vecchi sistemi R-22 |

Scegli in base al refrigerante (per esempio., L'R410a necessita di una tolleranza di pressione maggiore) e conteggio dei circuiti: fino a 12 per bobine di grandi dimensioni.

Importanza nei sistemi HVACR

Il distributore di refrigerante non è negoziabile per l'efficienza nei moderni sistemi HVACR. Promuove un trasferimento di calore uniforme, ridurre il consumo di energia garantendo che ogni sezione della batteria evapori il refrigerante in modo ottimale. Senza di esso, i sistemi soffrono:

- Raffreddamento non uniforme: Punti caldi/freddi nelle camere.

- Sovraccarico del compressore: Ritorno di flusso dovuto a un flusso squilibrato.

- Perdite di efficienza: Fino a 15% bollette energetiche più elevate.

In contesti commerciali, prolunga la vita dell'apparecchiatura riducendo al minimo lo stress termico. Per ricerche eco-consapevoli come “risparmio energetico del distributore di refrigerante,” nota che supporta transizioni a basso GWP, in linea con le normative EPA.

Guida all'installazione per distributori di refrigerante

La corretta installazione del distributore di refrigerante è fondamentale per evitare perdite o restrizioni. Seguire sempre le specifiche del produttore (per esempio., Linee guida Parker Sporlan). Strumenti necessari: chiave dinamometrica, flusso, torcia per brasatura.

Passo dopo passo:

- Preparare il sistema: Evacuare il refrigerante; isolare l'evaporatore.

- Montare il distributore: Posizionare orizzontalmente sopra l'intestazione della bobina, 6-12 pollici da TXV. Fissare con fascette.

- Collegare l'ingresso: Brasare o imbullonare l'uscita TXV; utilizzare ASC (Selettore distributore automatico) se necessario per la ritenzione dell'ugello.

- Collegare i tubi di uscita: Tagliato a misura (abbinare i circuiti della bobina); le estremità svasate e si collegano con i sindacati. Garantire lunghezze uguali per l'equilibrio.

- Isolare e testare: Avvolgere con schiuma; prova di pressione a 300 psi, quindi controllare le perdite con azoto.

- Tassa e Commissione: Aggiungere refrigerante; monitorare il surriscaldamento (8-12Obiettivo °F).

Per Suggerimento: Per R410a, utilizzare provette più lunghe per una migliore miscelazione. Consultare i codici locali per la sicurezza.

Suggerimenti per la manutenzione per una maggiore durata

La manutenzione regolare del distributore di refrigerante impedisce 80% di fallimenti. Pianificare controlli biennali.

- Ispezione visuale: Cerca la corrosione, raccordi allentati, o residui di olio che indicano perdite.

- Orifizi puliti: Lavare con solvente se intasato; evitare gli abrasivi.

- Controllare il tubo: Assicurarsi che non vi siano pieghe; sostituire se diametro ridotto.

- Ottimizzazione a livello di sistema: Verificare la funzione TXV e il surriscaldamento; regolare il distributore se vengono rilevati squilibri di flusso.

- Purezza del refrigerante: Utilizzare i filtri per prevenire i detriti; cambiare ogni anno.

Per “pulizia del distributore del refrigerante,” per la maggior parte dei tipi è sufficiente un semplice soffiaggio di azoto. Questo allunga la vita 10+ anni.

Problemi comuni e risoluzione dei problemi per il distributore di refrigerante

La risoluzione dei problemi del distributore di refrigerante spesso rivela restrizioni o malfunzionamenti.

Sintomi: Bassa pressione di aspirazione, congelamento della bobina, o temperature irregolari.

| Problema | Cause | Risoluzione dei problemi |

|---|---|---|

| Distribuzione non uniforme | Ugello ostruito o lunghezze del tubo non uguali | Misurare i flussi; ridimensionare gli orifizi; equalizzare i tubi |

| Congelamento | Carica bassa o restrizione | Controllare il surriscaldamento; scongelare e ricaricare; controllare la presenza di detriti |

| Perdite | Rottura del giunto brasato | Saldare, riparare o sostituire; utilizzo 45% saldatura d'argento |

| Scarsa miscelazione | Venturi consumato | Sostituire il distributore; caduta di velocità di prova |

Usa i misuratori: Obiettivo per un surriscaldamento di 5-10 ° F. Se persistente, chiamare un professionista per evitare danni al compressore.

Conclusione

Padroneggiare il distributore di refrigerante sblocca l'efficienza, prestazioni HVACR affidabili. Dalla meccanica azionata da Venturi alla versatilità del tipo a ugello, questo componente garantisce il corretto funzionamento del sistema.

Ricordare: Installare correttamente, mantenere diligentemente, e risolvere i problemi in modo proattivo. Mentre i refrigeranti si evolvono verso la sostenibilità, i distributori si adatteranno: tieniti informato tramite risorse come ASHRAE.

Per saperne di più “migliori pratiche per i distributori di refrigerante,” aggiungi questa guida ai segnalibri.

Eventuali commenti?

Benvenuto, lascia un messaggio o ripubblicalo.