Tại sao cần thiết phải đặt bẫy dầu?

Khi có sự chênh lệch lớn về độ cao trong hệ thống đường ống làm lạnh giữa dàn bay hơi (đơn vị trong nhà) và thiết bị ngưng tụ ( Đơn vị ngoài trời), phải lắp bẫy dầu trên đường ống đứng để tránh dầu môi chất lạnh không hồi lưu hiệu quả về máy nén., nếu không thì có thể ảnh hưởng đến máy nén’ cuộc sống phục vụ.

Vai trò của dầu trong hệ thống lạnh

Dầu rất cần thiết trong máy nén lạnh vì nó bôi trơn các bộ phận chuyển động, giảm ma sát, và giúp bịt kín các bộ phận để duy trì áp suất.

Trong hầu hết các hệ thống, dầu trộn với chất làm lạnh và đi qua đường ống. Điều này là cần thiết cho sức khỏe của máy nén, nhưng điều đó cũng có nghĩa là dầu phải quay trở lại bình thường sau khi rời khỏi máy nén.

Trong tủ lạnh nhiệt độ thấp, ví dụ, sự thay đổi độ nhớt của dầu sẽ khiến việc quay trở lại trở nên khó khăn hơn.

Tóm tắt, quản lý dầu thích hợp là chìa khóa để ngăn ngừa hỏng hóc máy nén, đặc biệt là trong các hệ thống xử lý cảm lạnh cực độ.

| Loại dầu | Độ nhớt (cSt ở 40°C) | Khả năng trộn lẫn với chất làm lạnh | Sử dụng chung | Dữ liệu về hiệu suất |

|---|---|---|---|---|

| Dầu khoáng | 32-68 | Thấp với HFC | Hệ thống kế thừa | 10% hiệu quả thấp hơn trong các thiết lập hiện đại |

| Poe (Este polyol) | 22-100 | Cao với HFC/HFO | Điều hòa hiện đại | Cải thiện lợi nhuận bằng cách 20% ở nhiệt độ thấp |

| PAG (Polyalkylene Glycol) | 46-150 | Cao với R-134a | Ô tô | Giảm di cư bằng cách 15% |

So sánh các loại dầu trong hệ thống lạnh

Các vấn đề thường gặp khi không có bẫy dầu

| Vấn đề | Sự miêu tả | Dữ liệu tác động |

|---|---|---|

| Thiếu dầu | Hiệu suất quay trở lại máy nén thấp | 25% tỷ lệ thất bại cao hơn |

| Giảm hiệu quả | Tích tụ dầu bay hơi | 5-15% tổn thất truyền nhiệt |

| Thời gian ngừng hoạt động từ Slug | Cục dầu làm hỏng van | 10-20% chi phí sửa chữa tăng cao |

Lợi ích của việc lắp đặt bẫy dầu

Việc lắp đặt bẫy dầu mang lại nhiều lợi ích khiến chúng trở thành thứ bắt buộc phải có trong nhiều hệ thống làm lạnh.

Chúng bảo vệ máy nén bằng cách ngăn ngừa tình trạng thiếu dầu hoặc tắc nghẽn dầu, giúp kéo dài tuổi thọ của hệ thống và giảm chi phí bảo trì.

Hiệu suất năng lượng được cải thiện khi thiết bị bay hơi không có màng dầu cản trở quá trình trao đổi nhiệt.

Trong các ứng dụng thương mại, điều này có nghĩa là hoạt động đáng tin cậy trong thời gian tải cao điểm.

| Số liệu | Có bẫy | Không có bẫy | Dữ liệu lợi ích |

|---|---|---|---|

| Hiệu quả | 90-95% | 75-85% | 10-20% nâng đỡ |

| Tuổi thọ | 10-15 năm | 7-10 năm | 20-30% sự mở rộng |

| Chi phí năng lượng | $800/năm | $1,000/năm | 15-20% Tiết kiệm |

Khi nào nên lắp đặt bẫy dầu?

1. Khi thiết bị ngưng tụ cao hơn thiết bị bay hơi

Có đường ống đứng giữa dàn bay hơi và ống hút chính. Vì dầu làm lạnh không bay hơi bên trong thiết bị bay hơi, nó tích lũy ở phía dưới. Khi tích tụ quá nhiều dầu, nó sẽ chặn ống hút.

Nếu lắp bẫy dầu ở đáy thiết bị bay hơi, lượng dầu chứa trong bẫy sẽ không quá nhiều. Ngay khi bẫy gần đầy, chênh lệch áp suất hai bên sẽ đủ để “bơm” dầu ra khỏi bẫy, đẩy nó lên ống hút nằm ngang phía trên, và sau đó cho phép nó chảy trở lại máy nén.

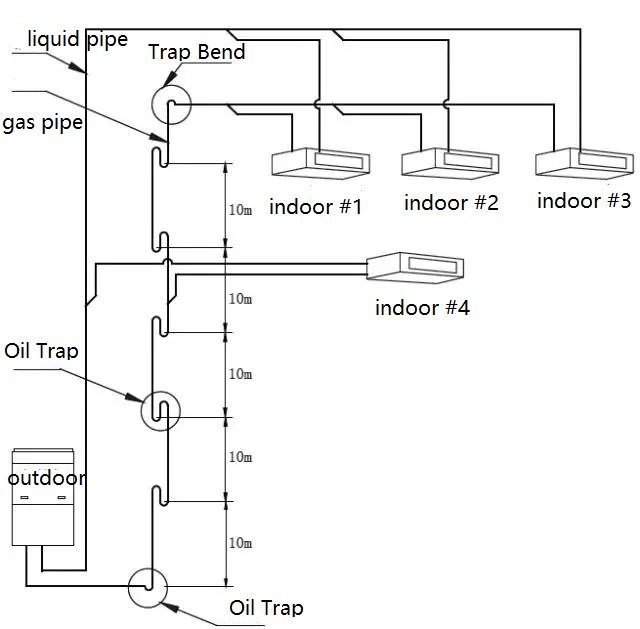

Nếu ống đồng thẳng đứng rất dài và có lo ngại rằng dầu có thể không được bơm hết lên trên, nên lắp bẫy dầu định kỳ dọc theo ống đứng (Ví dụ, cứ sau 6 ~ 10 mét) để đảm bảo dầu sẽ quay trở lại máy nén theo từng giai đoạn.

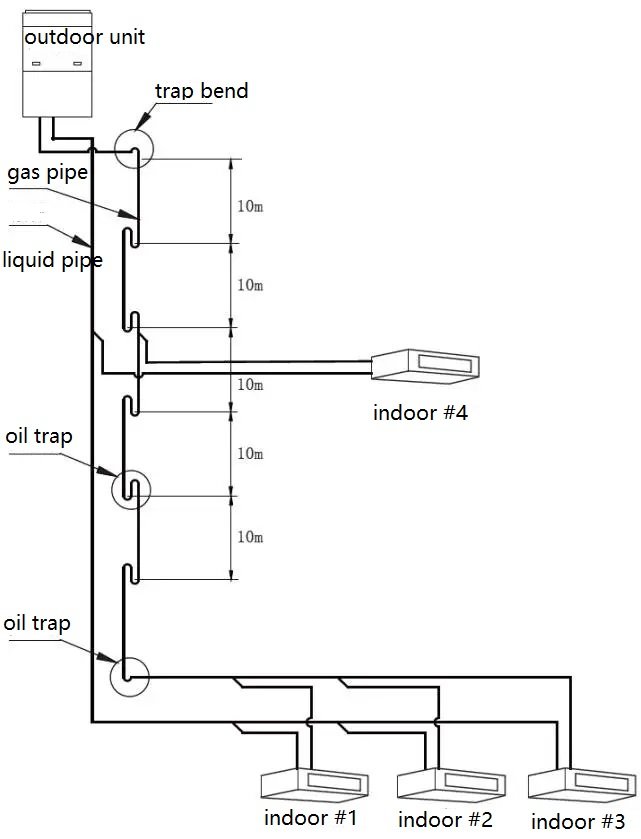

2. Khi thiết bị ngưng tụ thấp hơn thiết bị bay hơi có chênh lệch chiều cao lớn

Ngay cả khi không có bẫy dầu, dầu sẽ tự động chảy ngược về máy nén nhờ trọng lực. Tuy nhiên, mối lo ngại ở đây là quá nhiều dầu có thể quay trở lại cùng một lúc, khiến máy nén bị “sên lỏng” (sên dầu).”

Để tránh điều này, nên lắp bẫy dầu định kỳ (Ví dụ, cứ sau 6 ~ 10 mét) dọc theo đường ống hút để dầu dần dần quay trở lại máy nén theo từng giai đoạn.

3. Trong quá trình hoạt động tải thấp

Dầu có thể tích tụ trong bẫy, nhưng do tốc độ làm lạnh hạn chế, hiệu ứng quay trở lại chỉ do chênh lệch áp suất khi bẫy gần bị chặn là rất nhỏ. Điều quan trọng là thường xuyên tăng công suất máy nén để tăng tốc độ hút và cải thiện khả năng hồi dầu..

Nếu tốc độ hút có thể tăng đến mức đủ cao, thì không cần bổ sung thêm bẫy dầu. Tuy nhiên, trong thực tế, trong điều kiện tải thấp, hiệu ứng trao đổi nhiệt bên trong khiến công suất máy nén tăng quá mức, điều này có thể dẫn đến các vấn đề về điều khiển hệ thống như áp suất hút quá thấp và thiếu lực hút quá nhiệt.

Điều này có nghĩa là việc tăng tốc độ hút bị hạn chế. Vì thế, khi có sự chênh lệch chiều cao lớn, cần sử dụng bẫy dầu để thu hồi dầu từng bước.

Nguyên tắc lắp đặt bẫy dầu

1. Khi có sự chênh lệch độ cao giữa dàn lạnh và dàn nóng, lắp đặt bẫy dầu trên phần thẳng đứng của khí (hút) ống cứ sau 8 ~ 10 mét từ dưới lên trên.

Bẫy dầu có thể được chế tạo bằng cách sử dụng hai chỗ uốn hình chữ “U” hoặc một chỗ uốn hình chữ “O”, với chiều cao gấp 3 ~ 5 lần đường kính ống.

Còn gì nữa, lắp đặt bẫy dầu ở điểm thấp nhất và uốn cong bẫy ở điểm cao nhất.

2. Ống xả nên thiết kế giống như ống hút, phải xem xét: kiểm soát sụt áp, đảm bảo hồi dầu thích hợp, và ngăn ngừa sự trượt của chất lỏng, tiếng ồn, và rung động.

| MỘT | MỘT | r | C |

|---|---|---|---|

| mm | inch | mm | mm |

| Φ19.05 | 3/4 | ≥34 | 105 |

| Φ22,2 | 7/8 | ≥31 | 150 |

| Φ25,4 | 1/1 | ≥45 | 150 |

| Φ28,6 | 9/8 | ≥45 | 150 |

| Φ34,9 | 11/8 | ≥60 | 250 |

| Φ38.1 | 12/8 | ≥60 | 350 |

| Φ41.3 | 13/8 | ≥80 | 450 |

| Φ44,45 | 7/4 | ≥80 | 500 |

| Φ54.1 | 17/8 | ≥90 | 500 |

Kích thước cho bẫy dầu và đường cong bẫy

(Nhận xét: “MỘT” có nghĩa là Đường kính ngoài bằng đồng, “r” có nghĩa là tối thiểu. Bán kính uốn cong của bẫy dầu, “C” có nghĩa là tối đa. Chiều dài ống thẳng giữa các bẫy dầu)

Yêu cầu kỹ thuật khi lắp đặt bẫy dầu

Dàn nóng bên dưới dàn lạnh

Dàn nóng phía trên dàn lạnh

Phần kết luận

Bẫy dầu rất cần thiết trong hệ thống lạnh để đảm bảo dầu quay trở lại máy nén thích hợp, đặc biệt là khi có sự khác biệt về chiều cao theo chiều dọc hoặc điều kiện tải thấp.

Bẫy dầu được lắp đặt đúng cách ngăn chặn sự tích tụ dầu, giảm nguy cơ hư hỏng máy nén, và giúp duy trì hoạt động hệ thống hiệu quả và đáng tin cậy.

Mọi ý kiến?

Chào mừng bạn để lại tin nhắn hoặc đăng lại.