Hoje vamos falar sobre tipos normais de compressores de refrigeração, Vamos mergulhar nele.

Compressor de refrigeração de pistão semi-hermético

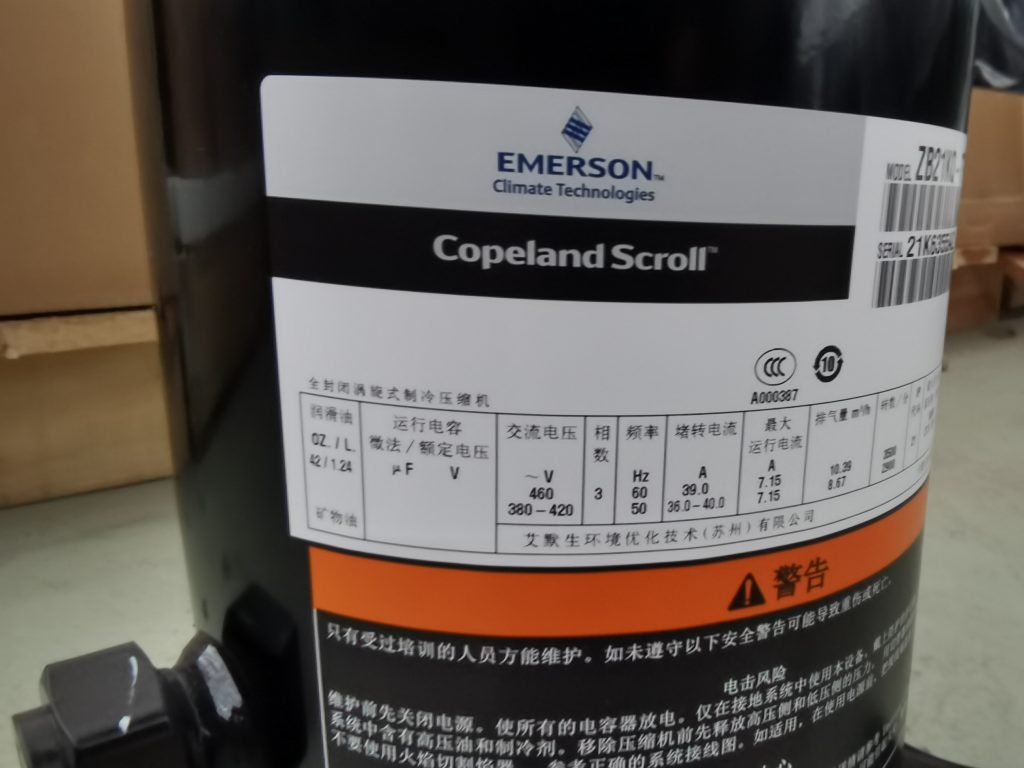

Entre vários tipos de refrigeração compressores, Os compressores de pistão são os primeiros e mais amplamente utilizados. Por exemplo, Os compressores de refrigeração de pistão semi-hermético são amplamente utilizados em equipamento de refrigeração. Fabricantes de compressores comuns incluem: Emerson, Bitzer, Sanyo, desejar,etc.

Características: Ampla faixa de pressão e capacidade de refrigeração, requisitos de material baixo, tecnologia madura, sistema de compressor simples, mas deve evitar ataque líquido.

Existem duas falhas comuns de pistão semi-hermético Compressores de refrigeração: falha mecânica e falha elétrica. As falhas mecânicas comuns incluem desgaste ou dano de bielas, eixos de manivela, Placas de válvula; As falhas elétricas são mais comuns no curto -circuito de enrolamento do motor, circuito aberto e esgotamento.

Compressor de refrigeração de rotores duplos

Os compressores de gêmeos são amplamente utilizados em eletrodomésticos, e cuja escala de exportação tem aumentado ano a ano. A taxa de crescimento composto em recente 5 anos é 12.8%. Agora muitos ar-condicionado Equipamento abaixo 7 HP (cavalos de potência) Escolha compressores de rotores duplos.

Características: poucas partes e estrutura simples, poucos peças de uso e operação confiável. Sem placa de válvula de sucção, Pequeno volume de folga, coeficiente de transmissão de gás alto, requisitos de precisão de alto processo, mau desempenho de vedação, e grande perda de vazamento.

Vantagens: Boa razão de eficiência energética de baixa frequência, não tão bom quanto rolagem (compressor)índice de eficiência energética de alta frequência, ruído um pouco maior, vibração e desgaste do que rolagem (compressor), vida mais curta do que rolagem (compressor), e difícil de obter um grande deslocamento.

Compressor de refrigeração de role

Roll compressor envolvido Rotor Rotor, role o estator, suporte, Anel de acoplamento cruzado, câmara de pressão de volta, e eixo excêntrico. Ele se dividiu em dois tipos: Compressão da câmara de baixa pressão e compressão da câmara de alta pressão.

O compressor da câmara de baixa pressão mostra que toda a concha externa está baixa temperatura, e a cavidade da concha (exceto a porta de escape e a cavidade de escape) é baixa pressão; O compressor da câmara de alta pressão mostra que toda a concha externa está alta temperatura, e a cavidade da concha (exceto a porta de admissão e a cavidade de admissão) é alta pressão.

Características: Operação suave, baixa vibração, ambiente de trabalho tranquilo, barulho baixo, vida longa, e alto valor eer. Eles são usados na refrigeração e ar-condicionado sistemas.

Compressor de refrigeração para parafuso

Compressor de refrigeração de parafuso envolvido invólucro, rotor, consequência, vedação do eixo, Balance Pistão, dispositivo de regulação de energia, etc. Tem dois parafusos com dentes em espiral malha e girando, causando o volume entre os dentes para mudar, concluindo assim o processo de sucção e compressão. Pode ajustar a capacidade de resfriamento passada 10% ~ 100%. Os compressores de refrigeração de parafuso agora são amplamente utilizados em refrigeração e Equipamento HVAC.

Características: Rotor e rolamentos’ resistência de força e desgaste são relativamente altos; O volume de escape é quase não afetado pela pressão de escape; Ele mantém uma alta eficiência em uma ampla gama de condições de operação, e pode alcançar a regulamentação de energia constante e é insensível à entrada líquida. Mas uma grande quantidade de retorno líquido também pode causar falha do compressor.

Compressor de refrigeração centrífuga

Os compressores de refrigeração centrífuga são compressores do tipo velocidade, que são equipamentos de rotação do impulsor. Eles dependem de impelidores rotativos de alta velocidade para trabalhar no gás para aumentar a pressão do gás. Compressores de refrigeração com uma única capacidade de unidade > 1.200kW são quase todos os compressores de refrigeração centrífuga, e os compressores centrífugos geralmente são usados em grande e extra grande ar-condicionado equipamento.

Características: Bom equilíbrio dinâmico, pequena vibração, poucas peças de uso, Longo ciclo de operação contínua, Fácil de obter compressão e aceleração de vários estágios, variedade de temperaturas de evaporação, pode se ajustar economicamente com problemas, baixa eficiência quando a capacidade de resfriamento é pequena.

Conclusão

Hoje, Exploramos cinco tipos comuns de compressores de refrigeração, Cada tipo tem características únicas adaptadas a aplicações específicas..

Algum comentário?

Bem-vindo deixe uma mensagem ou repost.