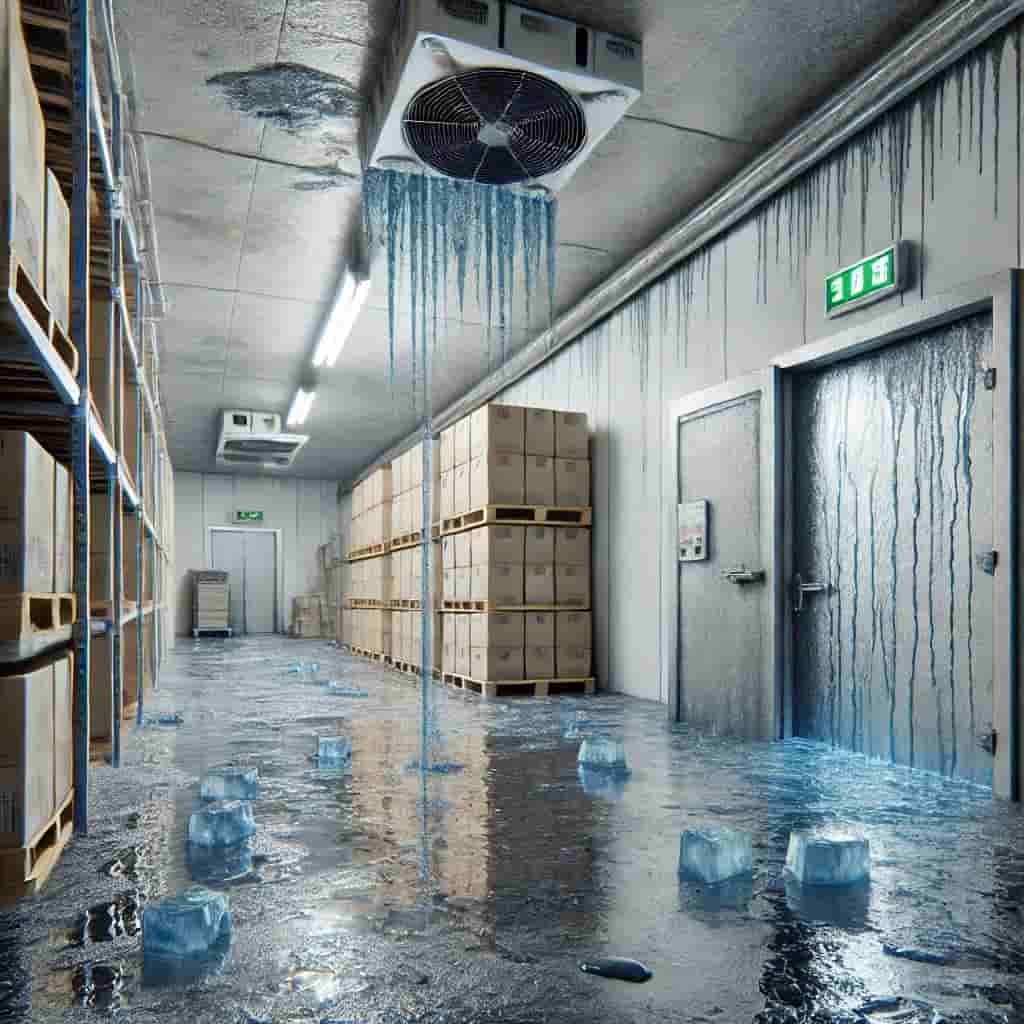

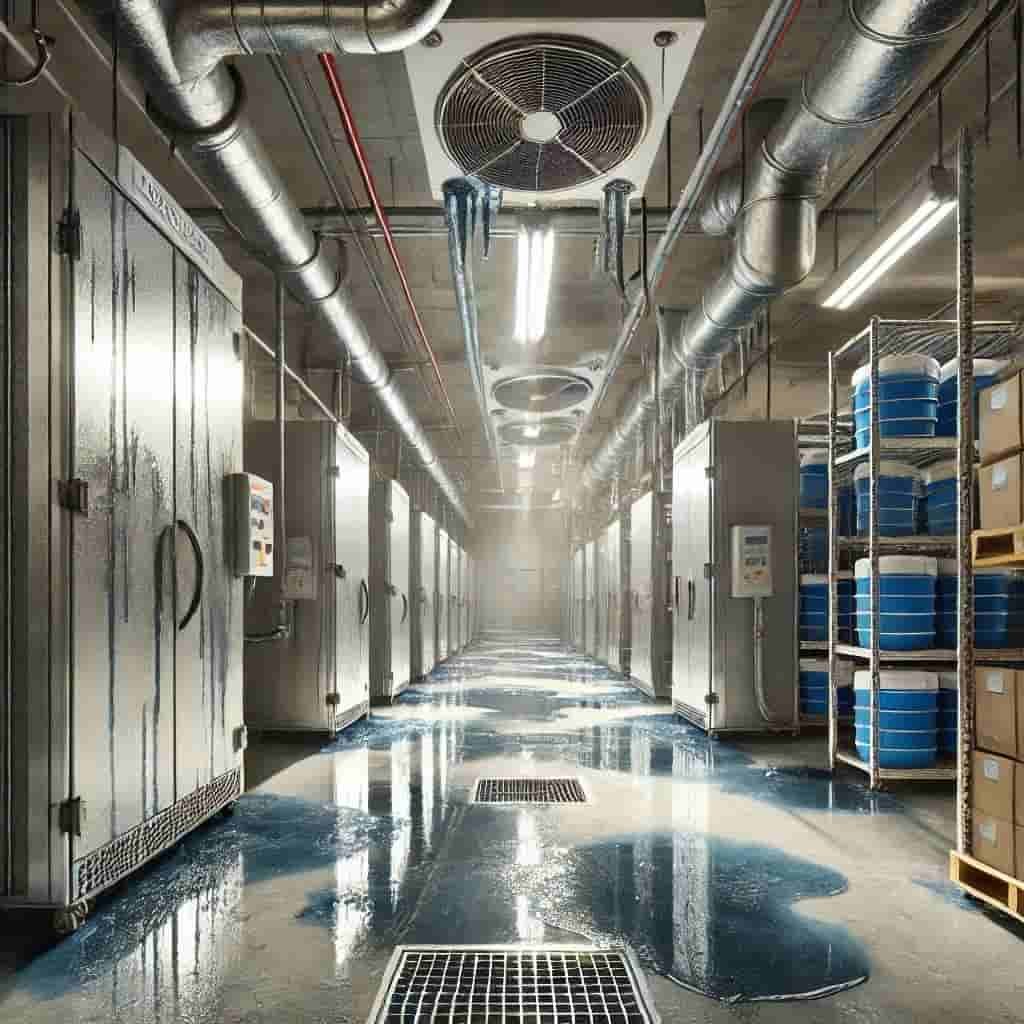

Câmaras frigoríficas são essenciais para preservar produtos perecíveis, mas o vazamento de água pode comprometer sua eficiência e causar danos dispendiosos. Se você notou poças, manchas úmidas, ou condensação em seu Quarto frio, é crucial identificar a causa raiz e resolvê-la imediatamente.

O vazamento de água não apenas atrapalha controle de temperatura mas também pode danificar produtos armazenados, equipamento, e a própria estrutura.

Desde acúmulo de condensação e sistemas de drenagem defeituosos até danos porta vedações e entrada externa de água, existem inúmeras razões pelas quais o seu Quarto frio pode estar vazando água. Compreender essas causas e implementar as soluções certas pode ajudá-lo a manter um ambiente livre de vazamentos., câmara fria eficiente.

Neste artigo, exploraremos as causas comuns de vazamento de água em câmaras frigoríficas, fornecer soluções detalhadas, e compartilhe medidas preventivas para garantir sua Quarto frio opera sem problemas.

Se você está lidando com pequenos gotas ou grandes vazamentos, Este guia o ajudará a solucionar o problema e protegerá seu investimento.

Causas e soluções para vazamento de água

1. Condensação pingando

Causas:

–Altos níveis de umidade dentro da sala fria

–Isolamento ruim nas paredes, tetos, ou pisos

—Temperatura diferenças entre o Quarto frio e seu ambiente

–Aberturas de portas frequentes, permitindo quente, ar úmido para entrar

Soluções:

–Instale a desumidificador Para controlar os níveis de umidade

–Melhorar isolamento usando materiais de alta qualidade e lacunas de vedação

–Use fechos de porta automáticos para minimizar porta aberturas

–Garanta a ventilação adequada para reduzir o acúmulo de umidade

2. Vazamento do sistema de drenagem

Causas:

–Linhas de drenagem entupidas devido a detritos, gelo, ou mofo

–Inclinação inadequada ou alinhamento da linha de drenagem

–Capacidade insuficiente da panela de drenagem para lidar com gelo derretido

Soluções:

–Limpe regularmente a linha de drenagem para evitar bloqueios

–Certifique-se de que a linha de drenagem esteja devidamente inclinada para um fluxo de água eficiente

–Instale uma bandeja de drenagem maior, se necessário

–Use um aquecedor de drenagem para evitar congelamento em ambientes mais frios

3. Vazamento de derretimento de gelo

Causas:

–Acúmulo excessivo de gelo nas bobinas do evaporador devido a sistemas de degelo defeituosos

–Bandejas de drenagem ou linhas de drenagem bloqueadas

–Drenagem inadequada durante ciclos de degelo

Soluções:

–Verifique e repare o sistema de degelo (temporizador, aquecedor, ou descongelamento com gás quente)

–Limpe a bandeja de drenagem e a linha de drenagem regularmente

–Certifique-se de que a bandeja de drenagem esteja devidamente alinhada para direcionar a água para a linha de drenagem

–Aumente a frequência dos ciclos de degelo, se necessário

4. Vazamento na vedação da porta

Causas:

Desgastado, rachado, ou danificado porta juntas

Portas desalinhadas que não fecham bem

Aberturas de portas frequentes, permitindo quente, ar úmido para entrar

Soluções:

–Inspecione e substitua a junta da porta danificada

–Ajuste ou repare o mecanismo da porta para garantir o alinhamento adequado

–Instalar porta automática fechos para minimizar aberturas de portas

–Use strip curtains to reduce air exchange when the door is open

5. Structural Leakage

Causas:

–Cracks or gaps in walls, pisos, or ceilings due to aging or poor construction

–Water ingress from external sources (por exemplo., rain or flooding)

–Poor sealing of joints or panels

Soluções:

–Inspect the structure for cracks and seal them with Quarto frio-specific sealants

–Reinforce the structure to prevent future damage

–Waterproof the exterior to protect against external water sources

–Ensure all joints and seams are properly sealed during construction or repairs

6. Refrigeration System Leakage

Causas:

Refrigerante leaks from damaged pipes or faulty components

Water pooling around the refrigeration unit due to improper installation

Condensation from uninsulated refrigerant lines

Soluções:

–Inspect the refrigeration system for leaks and repair them promptly

–Ensure proper installation and isolamento of refrigerant lines

–Check for water pooling around the unit and address the source of the leak

–Schedule regular maintenance with a qualified technician

7. Overflowing Drain Pan

Causas:

–Drain pan is too small to handle the volume of melted ice

–Improper positioning of the drain pan

–Blocked drain lines causing water to back up

Soluções:

–Instale uma bandeja de drenagem maior, se necessário

–Ensure the drain pan is properly positioned to direct water into the drain line

–Clean the drain line regularly to prevent blockages

–Check the drain pan for damage and replace it if needed

8. Vapor Barrier Leakage

Causas:

–Tears or gaps in the vapor barrier due to poor installation or damage

–Moisture penetrating the insulation due to a faulty vapor barrier

Soluções:

–Inspect the vapor barrier for tears or gaps and repair them

–Ensure the vapor barrier is properly installed and fully sealed

–Substitua a barreira de vapor se estiver danificada ou ineficaz

–Use materiais de alta qualidade para a barreira de vapor durante a construção ou reparos

9. Entrada externa de água

Causas:

–Entrada de água através de fissuras ou fendas na estrutura

–Exposição à chuva, inundação, ou vazamentos de encanamento próximos

–Má vedação do exterior da câmara fria

Soluções:

–Inspecione o exterior em busca de rachaduras ou lacunas e sele-as

–Eleve o Quarto frio ou instalar barreiras para proteger contra inundações

–Impermeabilize o exterior aplicando revestimentos protetores

–Garanta a vedação adequada de todas as juntas e costuras externas

10. Vazamento de derretimento de gelo

Causas:

–Acúmulo excessivo de gelo nas paredes, tetos, ou evaporador bobinas

–Fluxo de ar insuficiente causando resfriamento irregular

–Sistemas de degelo defeituosos levando ao acúmulo de gelo

Soluções:

–Descongele regularmente as serpentinas do evaporador e verifique o sistema de degelo

–Garanta o fluxo de ar adequado, organizando os itens armazenados e evitando obstruções

–Aumente a frequência dos ciclos de degelo, se necessário

–Inspecione e repare o sistema de degelo para evitar acúmulo excessivo de gelo

11. Vazamento na junta ou painel

Causas:

–Lacunas entre a parede, teto, ou painéis de piso devido a má vedação ou envelhecimento

–Instalação inadequada de painéis ou juntas

Soluções:

–Inspecione todas as juntas e costuras quanto a lacunas ou separações

–Use selantes específicos para câmaras frigoríficas para selar novamente as juntas

–Certifique-se de que os painéis estejam devidamente alinhados e fixados durante a instalação ou reparos

–Substitua painéis ou juntas danificadas, se necessário

12. Vazamento relacionado à umidade

Causas:

–Altos níveis de umidade dentro do Quarto frio

–Ventilação inadequada ou controle de umidade

–Aberturas de portas frequentes, permitindo quente, ar úmido para entrar

Soluções:

–Instale a desumidificador Para controlar os níveis de umidade

–Garanta a ventilação adequada para reduzir o acúmulo de umidade

–Usar porta automática fechos para minimizar aberturas de portas

–Monitore os níveis de umidade regularmente e ajuste as configurações conforme necessário

Medidas Preventivas Gerais

–Realize inspeções regulares do Quarto frio para sinais de vazamento de água.

–Treinar funcionários para identificar e relatar possíveis problemas com antecedência.

–Implementar um programa de manutenção programado para resolver os problemas de forma proativa.

–Mantenha um log de manutenção para rastrear os reparos e identificar problemas recorrentes.

Conclusão

O vazamento de água em sua sala fria pode levar a problemas significativos, De produtos estragados a danos estruturais.

No entanto, Ao entender as causas comuns - como condensação, drenagem com defeito, vedações danificadas, ou entrada de água externa - você pode tomar medidas proativas para resolver e evitar esses problemas.

Manutenção regular, isolamento adequado, e os reparos oportunos são essenciais para garantir o seu Quarto frio opera com eficiência e permanece livre de vazamentos.

Não deixe vazamento de água interromper suas operações ou comprometer seus produtos armazenados. Ao implementar as soluções descritas neste artigo e permanecer vigilante com as inspeções, Você pode proteger sua sala fria e prolongar sua vida útil.

Lembrar, um bem conservado Quarto frio Não apenas economiza dinheiro, mas também garante a qualidade e a segurança de seus itens perecíveis. Tome medidas hoje para manter sua sala fria em estado ideal!